About our architectural door surrounds

It’s not just trim; it’s a complete, engineered system designed to turn any doorway into a powerful architectural statement.

The anatomy of a grand entrance

An entrance is more than an opening; it’s the first handshake of a building. It establishes prestige, tells a story, and guides the human eye. Our door surrounds are engineered to be that powerful focal point. Crafted from a lightweight, high-density foam, they transform any standard doorway into a memorable architectural statement.

Each custom door surround system consists of precision-made parts that work in harmony:

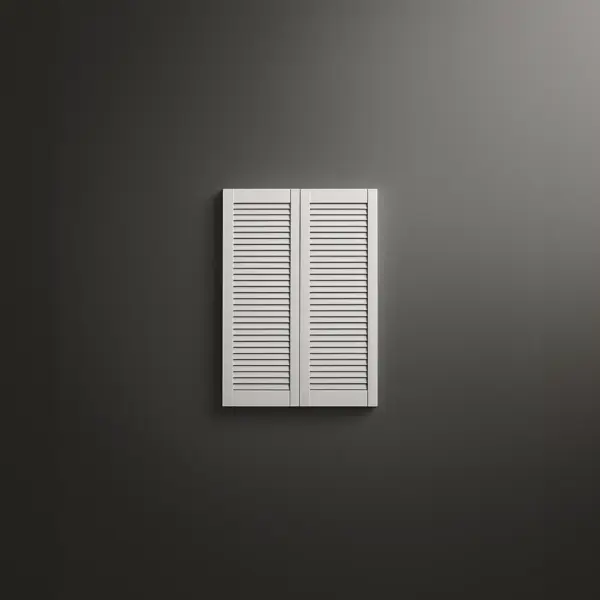

- Pilasters or Casing: The vertical elements (door casing or more decorative pilaster door surrounds) that frame the doorway, creating a sense of strength and presence.

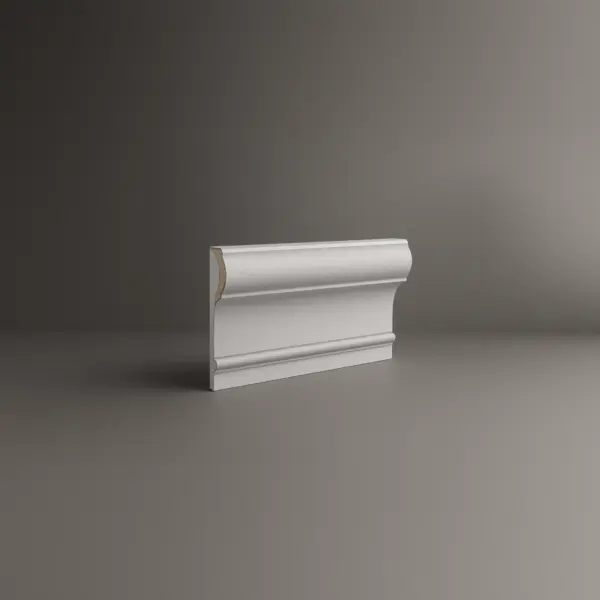

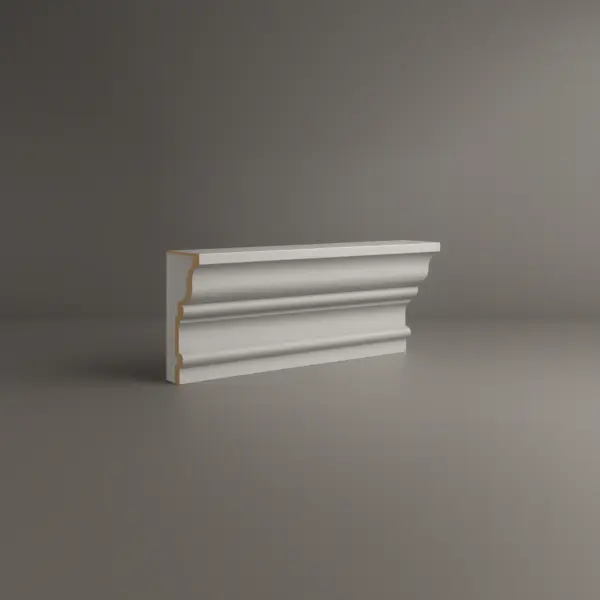

- Architrave & Frieze: The horizontal door architrave and decorative frieze that span the top, adding character and detail.

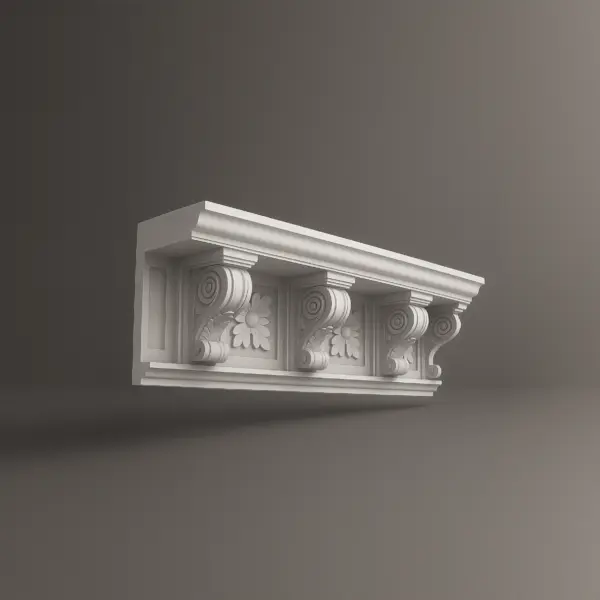

- Pediment: The crowning element (available in triangular, curved, or custom profiles) that serves as an unmistakable architectural statement.

We deliver a fully integrated, site-ready assembly that ensures your vision is executed with uncompromising technical accuracy.

The science behind a flawless finish: from foam to "stone"

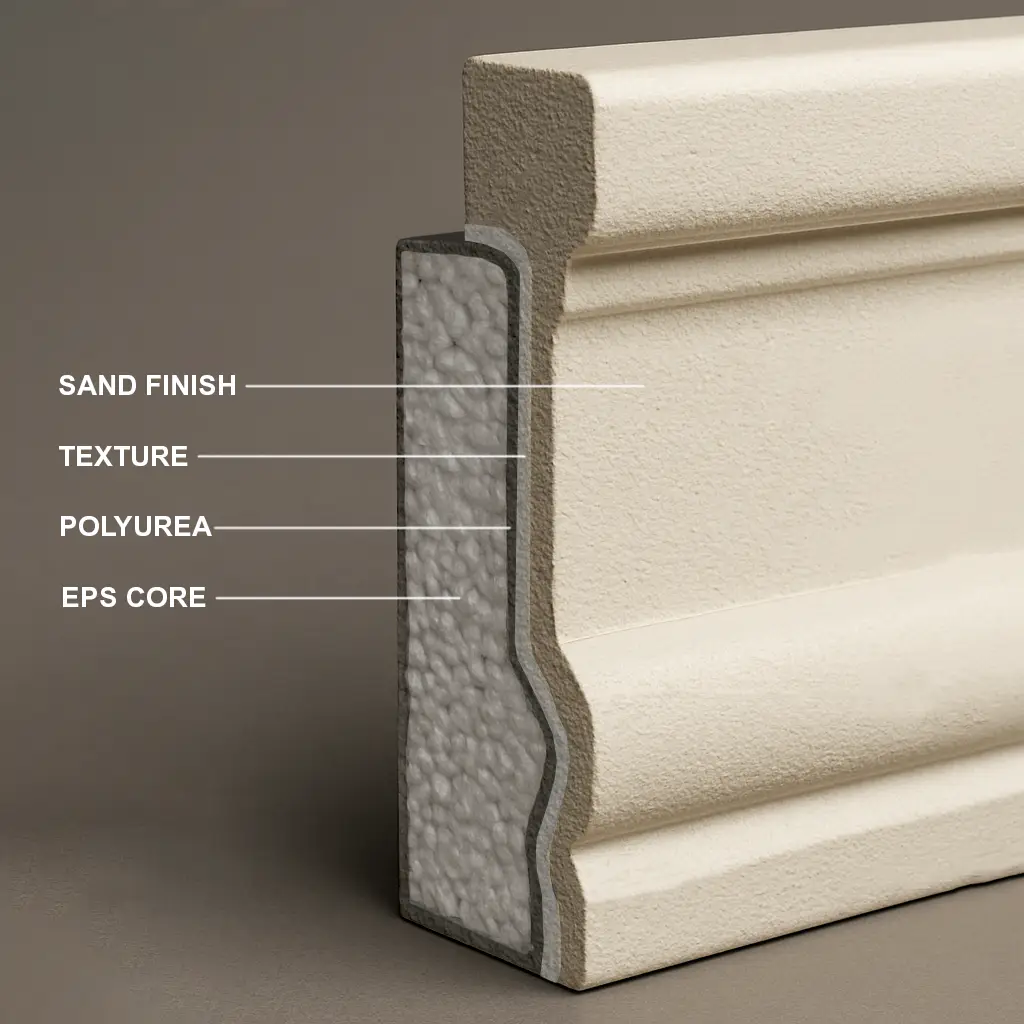

Our architectural door surrounds are not just foam; they are a composite masterpiece of material science. The process begins with a structural, high-density Expanded Polystyrene (EPS) foam core, precision-cut with CNC technology to match your exact architectural drawings. This ensures every curve, angle, and detail of your door molding is perfect.

This lightweight core is then encapsulated in our signature polyurea hard coat. This isn’t just a layer of paint; it’s a spray-applied, seamless, waterproof, and impact-resistant shell that transforms the foam into a monolithic structure with incredible durability. It’s the armor that makes our foam door surrounds ready for the real world.

The final step is the art: an integrated, architectural finish that provides the authentic texture and feel of limestone, precast concrete, or rich wood, while offering superior resistance to UV rays, weathering, and time. This is how we build entrances that are not only beautiful but brutally tough.

Assortment of architecture door surrounds

Foam door surrounds vs. traditional materials:

the smart choice

Choose a lightweight, durable, and fully customizable exterior door surround—built to impress, made to last.

Requires cranes, reinforced structures, and large crews. Inflates budget & timeline.

Delayed by weather, long curing times, and the need for specialized, expensive labor.

Prone to cracking, rot, pests, and water damage. Requires costly, recurring maintenance.

Custom work is slow, difficult, and astronomically costly, forcing design sacrifices.

High costs for material, labor, machinery, and inevitable long-term repairs.

Installs with a small crew, no cranes needed. Slashes shipping & structural costs.

Prefabricated system for rapid, predictable installation that accelerates your project.

Impervious to rot, cracks, and moisture. Zero maintenance required. Set it and forget it.

CNC-precision allows any complex or custom design. No creative compromises.

Significant savings on labor, equipment, and shipping. A smarter, more profitable investment.

Сustom architecture door surrounds

From Your Sketch to a Stunning Front Door Surround

Our process is engineered for clarity, speed, and precision—turning your vision into a ready-to-install reality.

It all begins with a deep dive into your project. We work as your technical partner to transform creative intent into a solid, actionable plan.

- Analyze Your Inputs: We review your architectural plans, CAD files, sketches, and inspirational images to understand your design from every angle.

- Define the Scope: In a collaborative consultation, we discuss the project’s aesthetic goals, site conditions, and technical requirements to ensure a perfect fit.

- Establish a Technical Blueprint: We finalize all specifications, from dimensions to finish textures, creating a clear roadmap for fabrication that aligns perfectly with your vision.

We bridge the gap between concept and cost, providing you with the clarity and confidence to move forward.

- Receive a Detailed 3D Visualization: We create and send you a precise 3D model, allowing you to see exactly how your custom architectural elements will look before production begins.

- Get a Transparent, Itemized Proposal: You receive a clear, comprehensive quote with no hidden fees. We believe in total transparency, so you know exactly what you’re investing in.

- Maintain Complete Control for Final Approval: We don’t proceed until you are 100% satisfied. You have the final say on the design and budget before we move to the next stage.

This is where your approved design becomes a physical reality, crafted with an obsessive focus on quality in our 45,000 sq. ft. workshop.

- Execute with Robotic Accuracy: Our state-of-the-art CNC hot-wire machines carve your architectural elements with flawless precision, matching your approved 3D models to the exact specification.

- Armor for a Century of Performance: Our skilled artisans apply our signature Polyurea hard coat, creating a seamless, impact-resistant, and weatherproof shell designed for decades of durability.

- Verify Through Rigorous Quality Control: Every single piece undergoes a multi-point inspection to ensure it meets our exact standards for shape, finish, and structural integrity.

Our commitment extends all the way to your job site, ensuring a smooth and successful installation.

- Protect with Secure, Custom Crating: We build specialized shipping crates for every project, guaranteeing your elements arrive in pristine, ready-to-install condition.

- Streamline Your Installation: Your pieces are delivered pre-assembled and lightweight, designed to slash on-site labor time and eliminate the need for heavy machinery.

- Support Your Crew to the Finish Line: We provide detailed installation guides and offer live Zoom support to answer your team’s questions, guaranteeing a perfect final fit.

It all begins with a deep dive into your project. We work as your technical partner to translate creative intent into a solid, actionable plan.

- Analyze Your Inputs: We review your architectural plans, CAD files, sketches, and inspirational images to understand your design from every angle.

- Define the Scope: In a collaborative consultation, we discuss the project’s aesthetic goals, site conditions, and technical requirements to ensure a perfect fit.

- Establish a Technical Blueprint: We finalize all specifications, from dimensions to finish textures, creating a clear roadmap for fabrication that aligns perfectly with your vision.

We bridge the gap between concept and cost, providing you with the clarity and confidence to move forward.

- Receive a Detailed 3D Visualization: We create and send you a precise 3D model, allowing you to see exactly how your custom architectural elements will look before production begins.

- Get a Transparent, Itemized Proposal: You receive a clear, comprehensive quote with no hidden fees. We believe in total transparency, so you know exactly what you’re investing in.

- Maintain Complete Control for Final Approval: We don’t proceed until you are 100% satisfied. You have the final say on the design and budget before we move to the next stage.

This is where your approved design becomes a physical reality, crafted with an obsessive focus on quality in our 45,000 sq. ft. workshop.

- Execute with Robotic Accuracy: Our state-of-the-art CNC hot-wire machines carve your decorative architectural shapes with flawless precision, matching your approved 3D model to the millimeter.

- Armor for a Century of Performance: Our skilled artisans apply our signature Polyurea hard coat, creating a seamless, impact-resistant, and weatherproof shell designed for decades of durability.

- Verify Through Rigorous Quality Control: Every single piece undergoes a multi-point inspection to ensure it meets our exacting standards for form, finish, and structural integrity.

Our commitment extends all the way to your job site, ensuring a smooth and successful installation.

- Protect with Secure, Custom Crating: We build custom shipping crates for your elements, ensuring they arrive on-site in pristine, ready-to-install condition.

- Streamline Your Installation: Your pieces are delivered pre-assembled and lightweight, designed to slash on-site labor time and eliminate the need for heavy machinery.

- Support Your Crew to the Finish Line: We provide detailed installation guides and offer live Zoom support to answer your team’s questions, guaranteeing a perfect final fit.

Our project gallery

Engineered solutions for your success

We build the solutions that make visionary projects possible—and profitable.

Stop value-engineering your vision. We fabricate custom door surrounds directly from your CAD files, giving you the freedom to design intricate, impactful entrances without the weight and budget constraints of stone or precast.

Create powerful curb appeal that accelerates sales. Our prefabricated systems install in hours, not weeks, slashing labor costs and eliminating delays. Deliver a premium look that commands a higher price, faster.

Elevate your brand presence from the curb. Our architectural door surrounds deliver the prestigious look of stone that attracts premium tenants and customers, with zero long-term maintenance costs. It’s an investment in a lasting first impression.

Design the ultimate statement entrance for your custom home. We create everything from grand pilaster door surrounds to elegant interior door surrounds, adding significant value and character to your property.

Engineered Solutions for Every Architectural Style

Discover our workHow a custom door surround redefines your property's value

A door surround isn’t just door trim; it’s the handshake of your building. It’s the first and last thing clients, visitors, and tenants interact with. A well-engineered surround instantly communicates quality, stability, and attention to detail—setting you apart before anyone steps inside.

- Curb Appeal That Commands a PremiumA strong, architectural entrance acts as a visual anchor, dramatically increasing a property's perceived value. It signals permanence and quality, which helps attract premium buyers and tenants and justifies higher price points.

- Durability That Protects Your InvestmentForget the endless cycle of painting wood or patching cracked concrete. Our polyurea-coated foam door surrounds are engineered to be virtually maintenance-free. They resist moisture, pests, and impact, ensuring your first impression remains flawless for decades. That’s not an expense; it’s a smart, long-term investment.

- Custom Design That Tells Your StoryYour entrance should be an extension of your brand or architectural vision. From a classic brick mold door look to a futuristic design, we can fabricate a surround that perfectly aligns with your property's identity, reinforcing your brand and making your building a landmark.

Client testimonials

From your first idea to the final installation — our process is clear, fast, and designed to make every detail simple.

FAQ

Why is foam a good material for front door or window surrounds in hot climates?

Foam handles temperature fluctuations exceptionally well. It does not crack, warp or absorb moisture. On a project in Ocala, temperatures reached nearly 145°F on the surface, yet all exterior door surrounds remained stable over multiple summers.

Can I order custom door surrounds based on my drawing?

Yes.

Are your door molding details difficult to install?

Not at all.

Do you replicate historical door architrave profiles?

Yes, of course — we frequently carry out historical reconstructions, including reproducing historic trims with strict accuracy. For example, one of our projects was in St. Augustine, where we manufactured a 1910s architrave using only a photograph provided by the client and a few measurements from which we created the drawings.

How durable are foam door surrounds?

Engineered architectural foam is resistant to moisture, ultraviolet exposure, and temperature fluctuations. This makes foam highly durable. And considering that we apply a special protective coating to every element, the service life increases significantly. This allows us to confidently provide a 20-year warranty on our architectural products.

Do you meet deadlines when producing large volumes of door surrounds?

Yes, of course. We often work with hotels, country clubs, and other commercial properties that require architectural elements in large quantities. Since our production facility is located in the United States, in Florida, we control every stage of manufacturing and can produce architectural elements at scale without compromising the consistency of their appearance.

Can I order door surrounds in a custom color that I specifically need?

Yes, absolutely. We specialize in custom, unique solutions, so based on the sample you provide, we will manufacture the architectural element and match its color and shade exactly to what you require.

What is the difference between a brick mold door and regular trim?

A brick mold door closes the installation gap between the door frame and the cladding. It creates a visually clean, seamless transition without unnecessary visual “noise,” while also protecting the doorway from moisture. Regular trim cannot perform this function effectively.

Are your architectural details suitable for coastal areas?

Yes, absolutely. Polystyrene foam does not absorb water and does not corrode. In addition, every product we manufacture is coated with a specialized protective layer. This makes our details ideal for coastal regions with high humidity, salty air and strong winds.

Can I combine door casing with door pediments?

Yes. Combinations help create expressive, hierarchy-based entrance design. For a Sarasota project we developed three unique combinations using consistent base profiles.

Is there a minimum order?

No. We fabricate anything from a single custom entrance surround to hundreds of standardized units.

Do you provide technical documentation that our project teams can use?

Yes, absolutely. Every product we manufacture comes with a complete package of technical documentation — from detailed drawings to installation guidelines and fastening recommendations. We also provide consultation throughout every stage of the project and additionally supply certificates confirming the quality of our architectural details and their compliance with all building and fire-safety regulations.

What is the standard production lead time?

Most orders are completed within 3–10 working days, although the exact timeline depends on the volume and complexity of the project.

& specification catalog

Get the definitive guide to our custom decorative architectural foam shapes. This free catalog is packed with hundreds of design profiles, detailed technical specifications, and real-world project applications.

Have a project in mind?

Our dedicated specialists are ready to collaborate with you, turning your concept into a detailed plan with a transparent budget. Let’s bring your vision to life!

More architectural shapes

We provide architects, builders, and homeowners with turnkey decorative elements that transform any project — fast, easy, and cost-effective.

Door surrounds

There are no small details. Sometimes the most insignificant decorative element becomes such a strong expressive accent in a building that it overshadows much more expensive and seemingly important structural components. This is exactly the role that decorative door surrounds play. Since the door is essentially the first thing a visitor notices when entering a home, the door surround sets the initial impression of the building. d by our 20-year warranty.

Custom door surrounds preserve the architectural concept, emphasize it, expand it, and visually unify and harmonize the space. Door casings, door trims, door moldings, door architraves, pilaster door surrounds and pediments are not mere decorative touches. They are what form the visitor’s first impression and complete the character of the building and the perception of the project as a whole.

For more than 25 years we have manufactured architectural elements in the United States, supplying fully finished, pre-painted exterior entrance surrounds and interior entrance portals engineered for accuracy, simplified installation and consistent performance. We function not as a supplier, but as an engineering partner who understands timelines, construction realities, budgets and the importance of predictable quality — all backe

What door surrounds are and what they actually do

Entrance surrounds are a set of architectural components that frame and articulate a doorway. Depending on the design, this system may include:

- door trim;

- door casing;

- door molding;

- door architrave;

- pilaster door surrounds;

- door pediments;

- brick mold door;

- foam door surrounds for interior or exterior use.

Their functions go far beyond aesthetics.

Entrance surrounds establish architectural logic. A simple door casing can make a façade look modern or classical. Door architrave defines proportions and organizes vertical and horizontal modules. Door trim hides structural transitions, protects edges and brings clarity to the junction between door frame and wall.

They also protect the envelope. Exterior entrance surrounds help channel water away from vulnerable joints. Brick mold door improves the performance of the door-to-cladding interface. Door molding minimizes the number of on-site adjustments, helping installers work faster and reducing the margin of error.

We have seen this pattern for decades: when entrance surrounds are engineered properly and match design plans precisely, the entire installation process becomes smoother, faster and more predictable.

Materials and technologies: why engineered foam outperforms heavy analogs

We manufacture exterior entrance surrounds and interior entrance surrounds using high-density architectural foam (60–90 psi compressive strength). This material has become a serious alternative to traditional substrates thanks to its performance advantages and design flexibility.

Key engineering benefits include:

- 6–12x lighter weight compared to concrete or stone;

- 35–50% reduction in installation labor;

- zero moisture absorption and no freeze-thaw damage;

- ability to replicate natural textures such as wood, stone or metal;

- minimal thermal expansion, eliminating cracking.

Every detail is cut with CNC precision down to 0.03–0.05 inch. Dimensional checks occur at each stage, ensuring accurate alignment with façade grids and architectural drawings. For projects where front entrance surrounds must follow strict rhythm and symmetry, this level of accuracy is indispensable.

All products arrive fully finished and painted — no sanding or coating on site. This eliminates an entire trade from your schedule and protects finishes from job-site conditions.

Engineering comparison table

| Parameter / Material | “Stone Heavyweight” (concrete/stone) | “Metal Perfectionist” (aluminum/steel) | “Engineered Foam Profile” (our entrance surrounds) |

|---|---|---|---|

| Weight per linear foot | 45–70 lb | 20–35 lb | 3–6 lb |

| Load on structure | Very high | Moderate | Minimal |

| Risk of thermal cracks | High | Low | Near zero |

| Labor cost compared to baseline | 100% | 70–85% | 45–55% |

| Shape flexibility | Limited | Moderate | Extremely flexible |

| Fit with non-standard drawings | Poor | Medium | Excellent |

| Alignment with façade modules | Requires corrections | Often acceptable | Precisely engineered |

| Need for on-site finishing | Yes | Often | No |

| Service life | 15–25 years | 20–30 years | 20+ years with 20-year warranty |

Varieties and real applications of door surrounds

Front entrance surrounds: the architectural handshake

Front entrance surrounds shape the first impression of the architecture. Whether it’s a residential complex, a high-end boutique hotel or a corporate building, the important point is this: a seemingly small and relatively inexpensive architectural detail can carry far more emotional and visual impact than the entire façade, especially if there are no additional decorative components.

A few years ago a medical center in Jacksonville needed a strong, monumental entrance. Heavy materials would slow installation and overload the structure. We engineered 64 lightweight foam details, all pre-assembled and pre-painted. Installation took less than a week. The façade gained gravitas, while the contractor stayed on schedule — a rare combination in fast-track construction.

Front entrance surrounds help:

- anchor the main entrance visually;

- emphasize brand identity;

- stretch or elevate the doorway proportionally;

- unify several façade entrances into one architectural system.

Door pediments: shadow, sculptural depth and storytelling

They create the dynamics of a 3D effect and the appearance of sculptural depth. For example, triangular shapes bring a sense of formality to the façade, while curved lines soften it and make it more fluid and streamlined. Multi-layered door pediments create a beautiful play of shadows that looks like a changing pattern throughout the day.

For instance, during a project in Savannah, the developer told us he wanted to achieve a sense of depth above each entrance using a stone-like texture. At the same time, he did not want to use heavy materials, of course, so he came to us for foam architectural details. We created curved pediments with a finish replicating natural limestone. For a long time, most residents were convinced it was real stone. The illusion worked perfectly, and we achieved the exact visual effect that highlighted the character and distinctive style of the building.

Pediments are ideal when a design requires:

- an accent above the doorway;

- classical nuance in a contemporary design;

- visual height without modifying structural openings.

Pilaster door portals. Excellent visual impact with minimal weight

Pilaster surrounds for entrances and windows add visual expression and rhythm to a building. They work exceptionally well on commercial façades, and we can say that pilasters are an excellent choice when you need vertical accents, subtle façade segmentation, and stylistic continuity between multiple door openings.

Custom door portals for those for whom standard solutions are not enough

This is where the true engineering and custom work of our team is fully revealed. The most expressive and unique entrance groups do not come from catalogs. They are drawn and developed by hand, creating a distinct style, character, and identity.

We had a project in Clearwater where the architect sent us a hand-drawn symmetrical entrance concept featuring complex curves and a highly unusual design. When we transformed it into 3D models and developed the mounting system, it was already clear how unique the project was.

When we finally manufactured the foam modules and delivered the fully assembled elements, it turned out that the installation crew, using our drawings and instructions, assembled the project extremely quickly despite how unconventional it was.

Custom entrance surrounds are ideal for:

- hospitality and themed environments;

- branded experiences;

- heritage replication;

- complex façade geometries.

Brick mold door: the precision joint no one notices

Brick mold door protects the most problematic area — the gap between the door frame and cladding. In humid coastal regions this joint can become a maintenance nightmare unless detailed properly.

On a project in Ocala, previous installations led to water infiltration. We created precise, moisture-resistant brick mold profiles matched to the cladding thickness. Since installation, the joint has remained dry and visually seamless.

Interior portal surrounds: the geometry that holds the room together

Interior entrance surrounds influence corridor rhythm, reception lines and general spatial perception. Foam is particularly useful inside: it is lightweight, dimensionally stable and allows for crisp, modern profiles without overloading walls.

We frequently pair minimalistic door casing with subtle door or window molding to create calm, harmonious indoor transitions — especially in hotels, offices and mixed-use spaces.

Production and logistics: the architecture behind the architecture

| Stage | Description |

|---|---|

| 1. Engineering and 3D modeling | You can provide CAD files, PDFs, sketches or reference photos. We convert them into precise 3D models that include connection points, joint tolerances, alignment with façade modules and structural clearances. Complex shapes, curves and historical profiles are modeled with engineering accuracy. |

| 2. Dimensional coordination with architectural drawings | We cross-check every measurement against your architectural plans. Height references, grid alignment, cladding interfaces — all verified before production. This eliminates on-site improvisation and reduces cost risks for installers. |

| 3. High-precision fabrication and pre-assembly | Where possible we pre-assemble sections at the factory. Fewer joints mean faster installation and fewer potential issues. CNC machinery ensures profile continuity, clean radii and tight tolerances. |

| 4. Color matching and finishing | All details are factory-coated. Bring a fragment of your cladding, a paint chip or a color code — we match it. Consistent color can be critical when installing large volumes of front entrance faux wood surrounds across a long façade. |

| 5. Professional packaging and delivery | We collaborate with transport companies to deliver even oversized architectural pieces safely. We design packaging to protect profiles, arrange efficient truck loading and provide clear unloading instructions. |

| 6. Technical documentation and installation guidance | Along with the products you receive installation drawings, fastening recommendations, exploded diagrams of complex units and maintenance guidelines. We remain available throughout construction to answer technical questions. |

Why it is beneficial to work with us

Working with us means gaining a reliable engineering partner, not just a supplier of finished products. We manufacture our elements within the United States and control quality, timelines, and the materials we use at every stage of production. First, this eliminates dependency on overseas logistics, and second, it minimizes risks to your project schedule.

We specialize in custom, fully individualized solutions. Whether you need front entrance surrounds, pilaster surrounds, door pediments, or a complex historically styled architrave, we adapt to all your ideas and architectural intent, and we are ready to create a design that is meaningful and necessary specifically for your project. Our engineers develop the geometry, proportions and dimensions, prepare 3D models, and also take on the development of mounting strategies and installation details for the finished elements.

Our materials are lightweight, durable and environmentally safe. They also comply with all building and fire-safety standards. Architectural foam reduces structural loads, which is especially important in renovation projects, including historical buildings. It also shortens installation time and requires no additional treatment or maintenance afterward. Architectural foam does not corrode, does not crack, and has excellent resistance to moisture absorption.

We support you at every stage of working with us. Your project is managed by a personal manager who oversees all details and is ready to respond to any changes in your project. We can also provide storage space at our facility for your finished products until you are ready to receive them on site. And most importantly, we take responsibility for the final result. With a 20-year warranty and decades of experience behind every design decision, we provide reliable architectural solutions that maintain their appearance and structural integrity for years.

If you’re looking for a precise, visually compelling and technically sound solution, request a quote — we prepare estimates within minutes.

& specification catalog

Get the definitive guide to our custom decorative architectural foam shapes. This free catalog is packed with hundreds of design profiles, detailed technical specifications, and real-world project applications.

Have a project in mind?

Our dedicated specialists are ready to collaborate with you, turning your concept into a detailed plan with a transparent budget. Let’s bring your vision to life!