About our architectural louver & shutter systems

Engineered for seamless integration, our systems turn functional necessities into defining architectural features.

Built for architectural impact

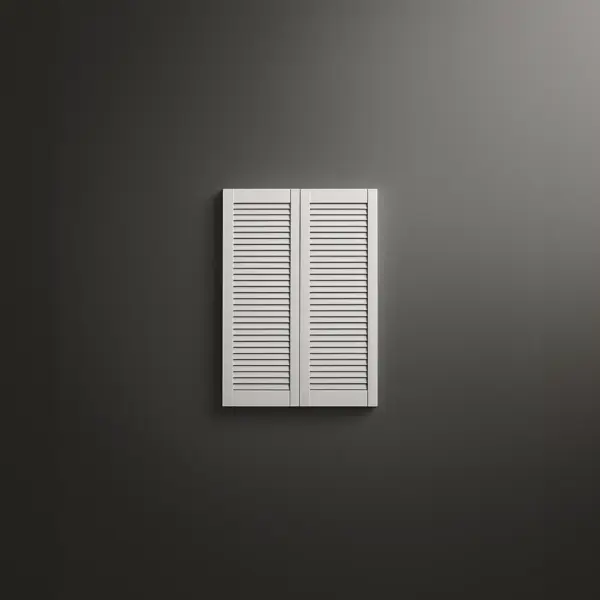

Forget flimsy, generic vents. Our architectural louvers and shutters are engineered as integral design elements. Crafted from a high-density, structural composite, they replicate the substance and visual weight of traditional materials while eliminating the engineering headaches. Whether you need functional ventilation, a decorative privacy screen, or statement-making decorative window shutters, our systems provide a powerful, sophisticated finish for any facade.

Each system is a precision-fabricated solution, not just a product:

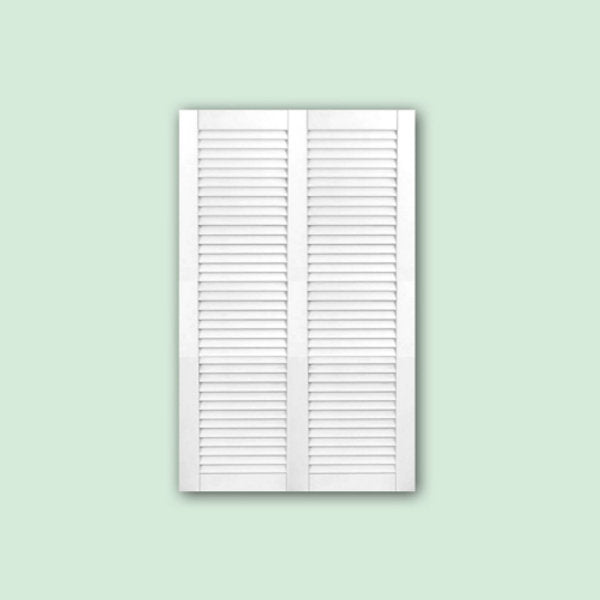

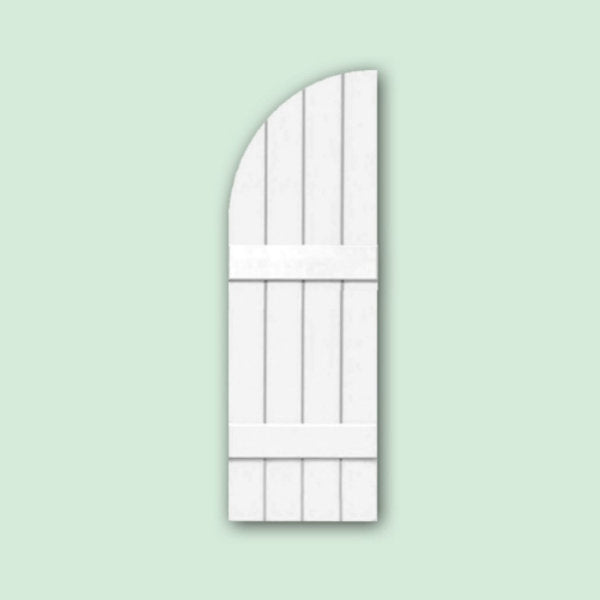

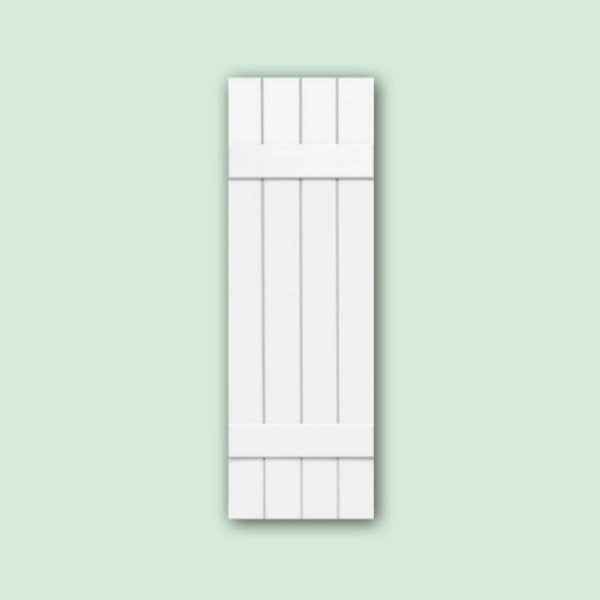

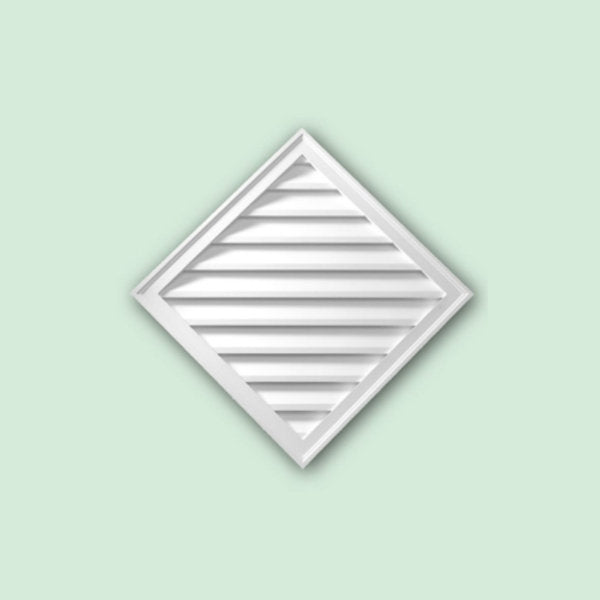

- Louver & Shutter Panels: The core of the design, available in countless styles, from modern blade profiles to classic colonial shutters.

- Integrated Framing: A seamless frame that ensures structural integrity and a clean, built-in look.

- Concealed Mounting: Engineered for a flawless finish with no visible hardware, preserving the purity of your design.

Get a fully integrated system that installs with architectural precision.

The engineering behind flawless form and function

Our architectural louver and shutter systems are built on a foundation of advanced material science, engineered for a century of performance. The core is a structural, high-density Expanded Polystyrene (EPS) foam, precision-cut with CNC technology to achieve perfect geometry and crisp, clean lines.

This lightweight core is then fully encapsulated in our signature polyurea hard coat. This isn’t paint; it’s a spray-applied elastomer that cures in seconds to form a seamless, waterproof, and impact-resistant shell. This process transforms the foam into a monolithic structure with incredible strength, ready to face hurricane-force winds and extreme weather without cracking, warping, or rotting.

The final layer is a high-performance, UV-stable architectural paint, matched to your exact color specifications. This advanced construction makes every decorative shutter and louver system robust, elegant, and virtually maintenance-free for its entire service life.

Assortment of

louvers & shutters

EPS composite louvers vs. traditional materials

Stop fighting the inherent flaws of wood, vinyl, and metal. Choose a lightweight, endlessly customizable, and ultra-durable solution engineered for the 21st century. Built to last, and proudly made in the USA.

Requires cranes, large crews, and costly structural engineering. High transport costs.

Installs in days or weeks. Requires on-site cutting, assembly, and finishing. Prone to weather delays.

Prone to rot (wood), rust (metal), and cracking/fading (vinyl). Requires frequent repainting and repairs.

Custom designs are extremely expensive or impossible to produce.

Expensive ongoing maintenance and eventual replacement costs.

Up to 90% lighter. No heavy machinery or structural reinforcement needed. Lower freight & labor costs.

Installs in hours. Prefabricated system arrives ready to mount, accelerating project timelines.

80-100 year lifespan. Waterproof, rot-proof, and insect-proof. Virtually zero maintenance required.

CNC technology creates any custom shape, profile, or style from your drawings.

Significant savings on labor, machinery, and shipping. No long-term maintenance costs.

Сustom louvers & shutters

How to order architectural louvers & shutters

From your initial sketch to job-site delivery—our process is engineered for your peace of mind.

It all begins with a deep dive into your project. We work as your technical partner to transform creative intent into a solid, actionable plan.

- Analyze Your Inputs: We review your architectural plans, CAD files, sketches, and inspirational images to understand your design from every angle.

- Define the Scope: In a collaborative consultation, we discuss the project’s aesthetic goals, site conditions, and technical requirements to ensure a perfect fit.

- Establish a Technical Blueprint: We finalize all specifications, from dimensions to finish textures, creating a clear roadmap for fabrication that aligns perfectly with your vision.

We bridge the gap between concept and cost, providing you with the clarity and confidence to move forward.

- Receive a Detailed 3D Visualization: We create and send you a precise 3D model, allowing you to see exactly how your custom architectural elements will look before production begins.

- Get a Transparent, Itemized Proposal: You receive a clear, comprehensive quote with no hidden fees. We believe in total transparency, so you know exactly what you’re investing in.

- Maintain Complete Control for Final Approval: We don’t proceed until you are 100% satisfied. You have the final say on the design and budget before we move to the next stage.

This is where your approved design becomes a physical reality, crafted with an obsessive focus on quality in our 45,000 sq. ft. workshop.

- Execute with Robotic Accuracy: Our state-of-the-art CNC hot-wire machines carve your architectural elements with flawless precision, matching your approved 3D models to the exact specification.

- Armor for a Century of Performance: Our skilled artisans apply our signature Polyurea hard coat, creating a seamless, impact-resistant, and weatherproof shell designed for decades of durability.

- Verify Through Rigorous Quality Control: Every single piece undergoes a multi-point inspection to ensure it meets our exact standards for shape, finish, and structural integrity.

Our commitment extends all the way to your job site, ensuring a smooth and successful installation.

- Protect with Secure, Custom Crating: We build specialized shipping crates for every project, guaranteeing your elements arrive in pristine, ready-to-install condition.

- Streamline Your Installation: Your pieces are delivered pre-assembled and lightweight, designed to slash on-site labor time and eliminate the need for heavy machinery.

- Support Your Crew to the Finish Line: We provide detailed installation guides and offer live Zoom support to answer your team’s questions, guaranteeing a perfect final fit.

It all begins with a deep dive into your project. We work as your technical partner to translate creative intent into a solid, actionable plan.

- Analyze Your Inputs: We review your architectural plans, CAD files, sketches, and inspirational images to understand your design from every angle.

- Define the Scope: In a collaborative consultation, we discuss the project’s aesthetic goals, site conditions, and technical requirements to ensure a perfect fit.

- Establish a Technical Blueprint: We finalize all specifications, from dimensions to finish textures, creating a clear roadmap for fabrication that aligns perfectly with your vision.

We bridge the gap between concept and cost, providing you with the clarity and confidence to move forward.

- Receive a Detailed 3D Visualization: We create and send you a precise 3D model, allowing you to see exactly how your custom architectural elements will look before production begins.

- Get a Transparent, Itemized Proposal: You receive a clear, comprehensive quote with no hidden fees. We believe in total transparency, so you know exactly what you’re investing in.

- Maintain Complete Control for Final Approval: We don’t proceed until you are 100% satisfied. You have the final say on the design and budget before we move to the next stage.

This is where your approved design becomes a physical reality, crafted with an obsessive focus on quality in our 45,000 sq. ft. workshop.

- Execute with Robotic Accuracy: Our state-of-the-art CNC hot-wire machines carve your decorative architectural shapes with flawless precision, matching your approved 3D model to the millimeter.

- Armor for a Century of Performance: Our skilled artisans apply our signature Polyurea hard coat, creating a seamless, impact-resistant, and weatherproof shell designed for decades of durability.

- Verify Through Rigorous Quality Control: Every single piece undergoes a multi-point inspection to ensure it meets our exacting standards for form, finish, and structural integrity.

Our commitment extends all the way to your job site, ensuring a smooth and successful installation.

- Protect with Secure, Custom Crating: We build custom shipping crates for your elements, ensuring they arrive on-site in pristine, ready-to-install condition.

- Streamline Your Installation: Your pieces are delivered pre-assembled and lightweight, designed to slash on-site labor time and eliminate the need for heavy machinery.

- Support Your Crew to the Finish Line: We provide detailed installation guides and offer live Zoom support to answer your team’s questions, guaranteeing a perfect final fit.

Our project gallery

Precision solutions for every architectural style

Whether you’re designing, building, or managing a property, our systems are engineered to meet your specific goals.

Finally, the freedom to design without material constraints. We fabricate to your exact CAD files, from sharp, minimalist louver screens to historically accurate decorative exterior shutter styles. We provide the technical partnership you need to execute your vision perfectly.

Accelerate your project timelines and reduce on-site labor costs. Our lightweight, prefabricated systems install in a fraction of the time of traditional materials, helping you deliver a high-end look on schedule and on budget.

Elevate your building’s facade from a simple wall to a branded architectural feature. Ideal for hotels, retail centers, and office parks that demand superior curb appeal with zero maintenance burden.

Achieve a truly custom look for your home. From functional Bahama shutters to elegant, fixed decorative window shutter designs, we create the perfect architectural accent to enhance your property’s value and beauty.

Before and after:

From functional necessity to architectural statement

Discover our workHow decorative louvers redefine your building’s identity

A louver or shutter is never just a functional object. It’s a deliberate design choice that communicates quality, character, and attention to detail. It’s a critical element that can complete a building’s story or undermine it.

- Create Architectural IntegrityA well-designed decorative louver adds rhythm, texture, and depth to a flat facade. It’s the finishing touch that demonstrates a cohesive architectural vision and elevates the entire structure from ordinary to exceptional.

- Signal Quality and DurabilityChoosing a robust, permanent solution over a flimsy, standard-issue one sends a powerful message. It shows an investment in quality that tenants, clients, and visitors can see and feel, building trust and reinforcing a premium brand image.

- Achieve Custom Brand AlignmentYour building's exterior is your brand's first handshake. With unlimited design and color options, our louvers and shutters can be tailored to perfectly match your brand’s aesthetic, whether it’s sleek and modern, classic and traditional, or bold and futuristic.

Client testimonials

From your first idea to the final installation — our process is clear, fast, and designed to make every detail simple.

FAQ

Can you match a custom color for my façade?

Absolutely. For a project in Fort Lauderdale, we matched our foam panels and shutters to a rare sandstone tone. The client doubted it was possible, but once installed, even the designer couldn’t tell the difference.

How long do your products last?

Over 20 years. Tested and proven — even in Florida’s humid, sunny climate, the material stays stable and vibrant.

What decorative exterior shutter styles do you offer?

Almost any you can imagine — from colonial and classic to minimalist and modern. We adapt to your design, not the other way around.

If everything you do is custom, doesn’t that make the process slow and expensive?

You might think so, but actually, it’s the opposite. Because we handle design and manufacturing ourselves, we control every stage — from modeling shutters to final delivery. Customization for us doesn’t mean “extra cost”; it means precision. Think of it as a perfectly tailored suit — it fits right the first time, so there’s no waste, no rework, no delays. Most of our custom orders ship within just a few weeks, complete with installation kits and full documentation.

What if my project has nonstandard dimensions?

Perfect — that’s our specialty.

What types of buildings do you work with?

All kinds — residential, commercial, and municipal. If there’s an architectural idea behind it, we’ll help make it real.

How fast can I get my order?

Usually within 2–4 weeks, depending on complexity. Since we produce everything domestically, timelines stay consistent.

So what happens years later? Does the material fade or get brittle under the sun?

That’s a question we love because it gives us a chance to talk about results we’ve seen ourselves. Our installations in Florida — and we’re talking about heat, humidity, storms — have been standing strong for more than a decade.

For instance, the façade we built for a hotel in Fort Lauderdale twelve years ago still looks fresh. The foam doesn’t crack, fade, or peel thanks to its UV-resistant coating and sealed-cell core. We’ve tested it in the toughest conditions, and it keeps proving its durability year after year.

Can I combine different styles?

Of course.

What about a warranty?

Yes, a 20-year standard warranty. Plus, we’re always available to assist with installation or technical documents.

We’ve seen other foam products before. How are yours any different?

Our foam decorative louvers and decorative shutters go through a multi-step finishing process: sealing, coating, texturing — until they look indistinguishable from natural materials. We remember one project in Savannah where we recreated aged oak shutters for a Victorian-style home.

When the homeowner saw them installed, she laughed — they looked like real wood but were three times lighter and completely weatherproof. That’s the kind of realism and quality we put into every piece.

& specification catalog

Get the definitive guide to our custom decorative architectural foam shapes. This free catalog is packed with hundreds of design profiles, detailed technical specifications, and real-world project applications.

Have a project in mind?

Our dedicated specialists are ready to collaborate with you, turning your concept into a detailed plan with a transparent budget. Let’s bring your vision to life!

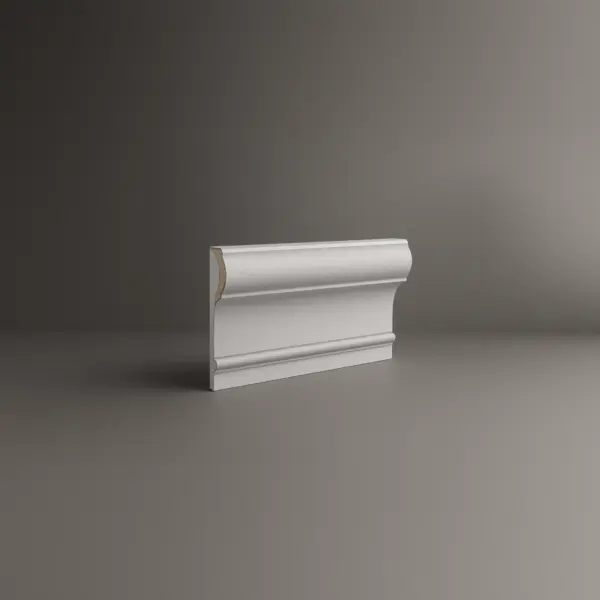

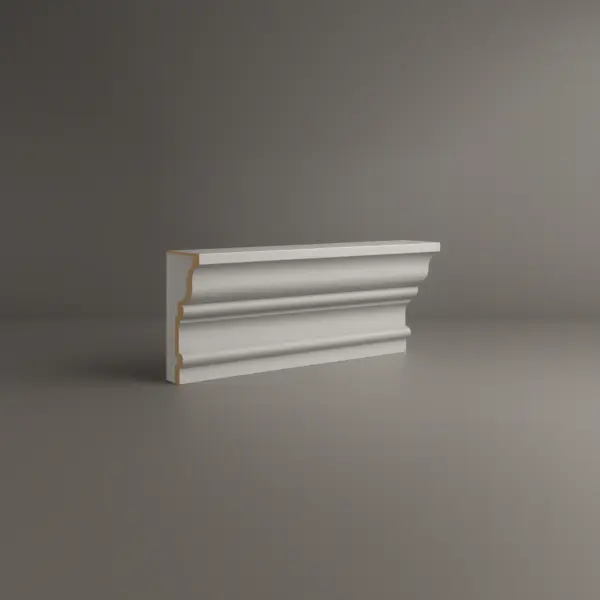

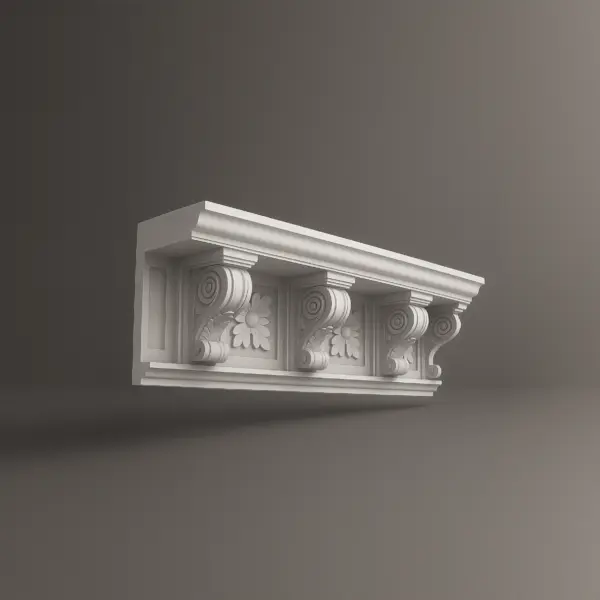

More architectural shapes

We provide architects, builders, and homeowners with turnkey decorative elements that transform any project — fast, easy, and cost-effective.

Decorative louver & shutters

When sunlight touches a façade and the lines of a decorative louver create a soft play of light and shadow, the building seems to come alive. There’s something almost musical about it — rhythm, harmony, the architecture breathing in time with the day. Over a quarter century, we at Decorative Architectural Shapes have learned to hear that rhythm — to see where a line becomes emotion and where a simple structure turns into the face of a brand.

For us, decorative louver panels and decorative window shutters are not just architectural accessories. They’re the accents that tell the story of a building — its character, its atmosphere, its identity. They shape the mood, elevate aesthetics, and help projects look luxurious and refined, even when the budget is perfectly optimized.

Today, architecture isn’t just about function. It’s about storytelling. And that’s exactly what we help our clients do.

What are decorative louvers and shutters

A decorative louver is a design instrument that gives a faсade depth, rhythm, and breath – enhancing a home’s curb appeal. It lets the architecture exhale.

Custom exterior shutters frame the window, completing the façade and giving it personality. From minimalist modern to colonial elegance — the range of forms and textures is limitless.

These elements make architecture feel alive:

- they visually structure the building surface;

- they help projects stand out among repetitive urban lines;

- they make properties look more expensive and sophisticated without unnecessary costs.

And all of this becomes possible thanks to modern materials and technology — the heart of our craft.

History and evolution

Once upon a time, shutters were made exclusively from wood — charming but demanding, like an old car that needs constant care. Then came metal versions: durable, yet cold and lifeless. And finally, a new era began — light, flexible, and full of texture that could mimic any style.

We’ve watched this evolution firsthand. Over the past quarter century, we’ve seen design trends move from ornate detailing to minimalist precision. Colors became more subtle, proportions cleaner, and expectations higher. Each era’s decorative exterior shutter styles reflected its spirit.

One memorable project took place in the historic center of Savannah. The client owned a Victorian-style home but wanted a fresh, authentic look — not a museum piece. We created foam shutters with a weathered oak texture: lightweight, water-resistant, maintenance-free. The result was so convincing that passersby thought it was real wood.

Materials and technology

At the core of our work is EPS foam, produced at our own U.S. facility. That means full control, stable quality, and absolute precision.

Foam offers endless possibilities — it can look like anything. We craft decorative louver panels that replicate oak, cedar, stone, even bronze. It’s all about your design vision.

| Feature | Technical Impact and Case Study |

|---|---|

| Lightweight Construction | Foam is several times lighter than plaster or concrete, reducing structural load and installation effort. In Jacksonville, a client replaced heavy plaster decorative panels with foam. The installation took two days instead of a week — no special equipment needed. The look remained identical, but the budget and timeline were significantly optimized. |

| Durable and weather-resistant | Foam doesn’t absorb water, rust, or fade — even under the Florida sun. |

| Eco-friendly | Our materials are safe, non-toxic, and sustainable. |

| Flexible design | Foam can be molded into any shape, allowing for an unlimited range of decorative exterior shutter styles — from classical to ultra-modern. |

| Quality assurance | Each piece undergoes precise geometry checks and coating inspection. |

| Predictable logistics | With full U.S. production, logistics stay predictable, and delivery timelines are transparent. |

Comparison with alternatives

Architects used to love plaster — its texture, its weight, its grandeur. But it demanded constant care. One project in St. Augustine proved that perfectly: the plaster faсade started cracking after only two years. We replaced those elements with foam replicas, identical in appearance but far superior in performance. The building kept its classic charm while becoming lighter, stronger, and maintenance-free and reaching an authentic appearance.

Unlike wood, foam never needs repainting and resists humidity. Unlike metal, it doesn’t rust or overload the structure. And unlike PVC, it doesn’t warp with temperature changes. Foam became the perfect balance of beauty, durability, and practicality.

| Material | Traditional Limitations | Architectural Foam Advantages |

|---|---|---|

| Plaster | Heavy and prone to cracking within short periods (as seen in St. Augustine); requires constant maintenance. | Provides identical authentic appearance but is lighter, stronger, and maintenance-free. |

| Wood | Vulnerable to humidity, rot, and insects; requires frequent repainting. | Naturally resists moisture and never requires repainting to maintain structural integrity. |

| Metal | Susceptible to oxidation (rust) and adds significant weight to the building structure. | Non-corrosive material that does not overload the building’s structural frame. |

| PVC | High thermal expansion leads to warping and joint separation during temperature fluctuations. | Superior thermal stability ensures the material remains straight and intact regardless of seasonal shifts. |

Varieties and applications

Classic charm with a modern soul

In Atlanta, a homeowner dreamed of recreating the look of a Charleston house — warm, traditional, but easy to maintain. We proposed decorative exterior shutter styles with a soft aged-wood texture. The result was timeless: a nostalgic look with modern convenience. Later, she told us it was the first time in years she could enjoy her house without worrying about repainting.

Architectural accents for brands

In Orlando, a French-style café wanted to create a sense of intimacy and charm. We produced decorative window shutters in a soft mint shade, finished with delicate black faux metal accents. They didn’t just frame the façade — they became part of the logo and visual identity. That’s what we love most: when design becomes storytelling.

Warranty, documentation, and support

We guide every project from design to installation. Each product is shipped with complete technical documentation, mounting recommendations, and clear guidance tailored to your architectural specifications.

Every piece is inspected, numbered, and covered by a 20-year warranty.

We assist with logistics and provide secure packaging to ensure safe transport.And if your team ever needs help during installation, our engineers are just a call away.

Where louvers and shutters are used

You’ll find decorative louvers and decorative shutters across many industries — from resort hotels to private homes and public buildings.

Commercial properties

In a Fort Lauderdale hotel, neutral façades came to life thanks to custom louvers that added rhythm and sophistication. Without them, the building felt flat. With them — dynamic and memorable. The foam structure easily withstands coastal humidity while maintaining a luxurious appearance.

Private residences

In Tampa, a seaside villa owner wanted a “light ocean breeze” aesthetic — without fading or corrosion. We created white decorative shutters with a subtle glossy finish. After three seasons of salt air and sun, the façade still looks brand new.

Foam gives architecture freedom — it allows it to be both modern and timeless. And we know how to help our clients find that perfect balance between beauty and reason.

Why it’s worth working with Decorative Architectural Shapes

We don’t just manufacture decorative louver panels or decorative shutter hinges — we create architectural solutions that make your projects stand out, perform better, and stay within budget.

Our engineers and designers know how to listen. We understand that behind every drawing lies an idea, and our mission is to bring it to life without compromise.

Decorative Architectural Shapes means:

- in-house production in the USA;

- fully customized design solutions;

- guaranteed precision and delivery times;

- consulting and technical support;

- we provide sample kits and 3D models so you can evaluate the material and precision of execution in advance.

Over the past quarter century, much has changed — architecture has become bolder, technology more precise. But one thing remains the same: the desire to create beautifully and reliably. That’s what connects us with our partners — from hotels to architectural studios.

If you’re looking for a reliable partner — not just a supplier — we’ll be there. Because at Decorative Architectural Shapes, we don’t just create decorative elements, especially shutters. We create architectural stories.

& specification catalog

Get the definitive guide to our custom decorative architectural foam shapes. This free catalog is packed with hundreds of design profiles, detailed technical specifications, and real-world project applications.

Have a project in mind?

Our dedicated specialists are ready to collaborate with you, turning your concept into a detailed plan with a transparent budget. Let’s bring your vision to life!