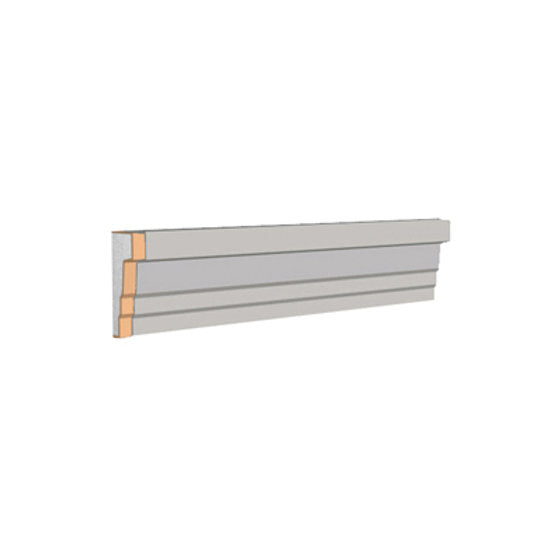

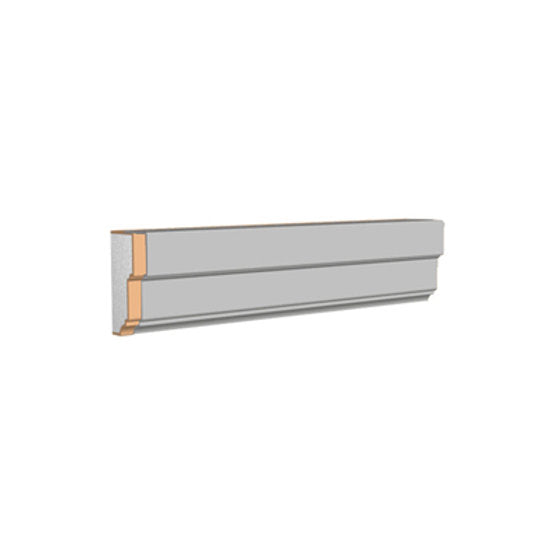

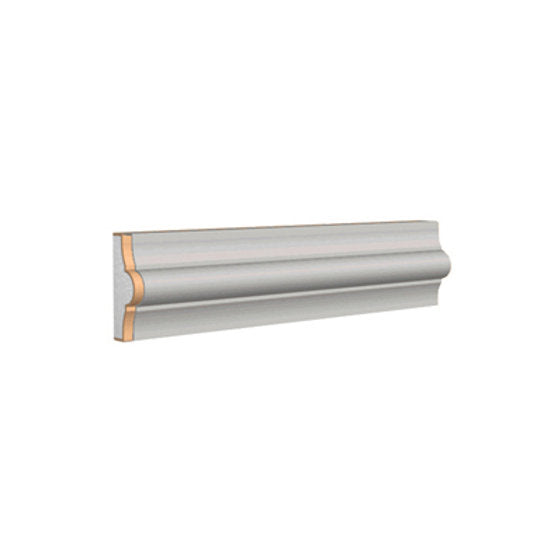

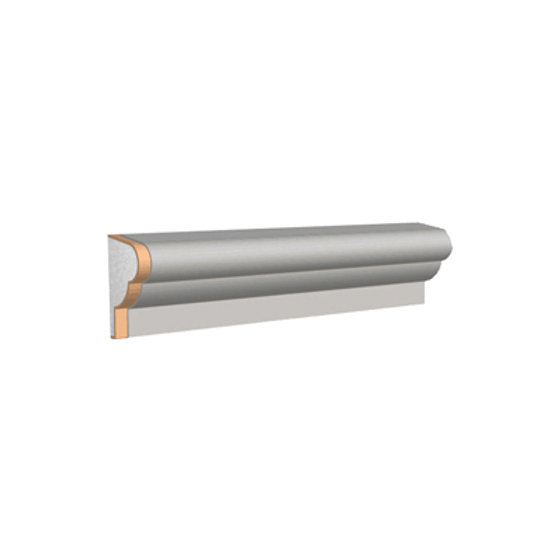

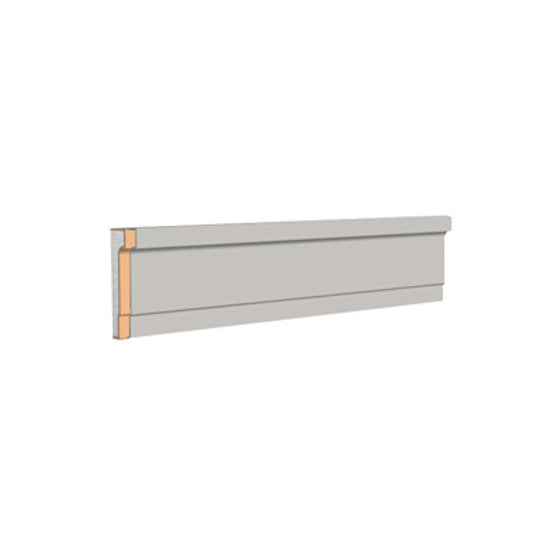

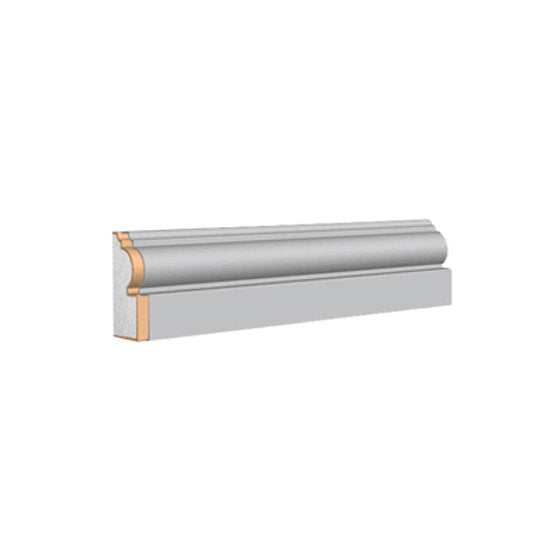

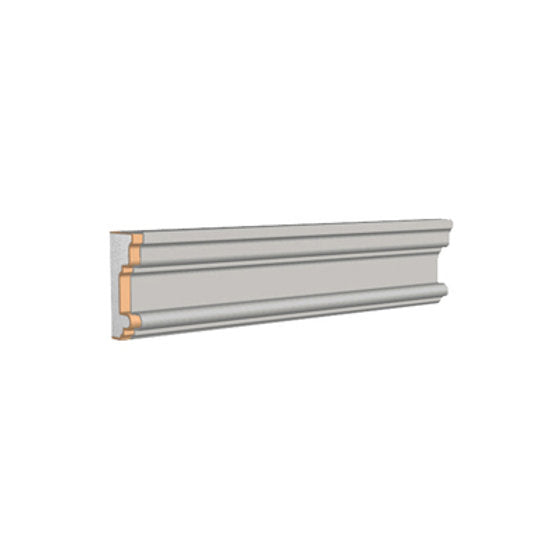

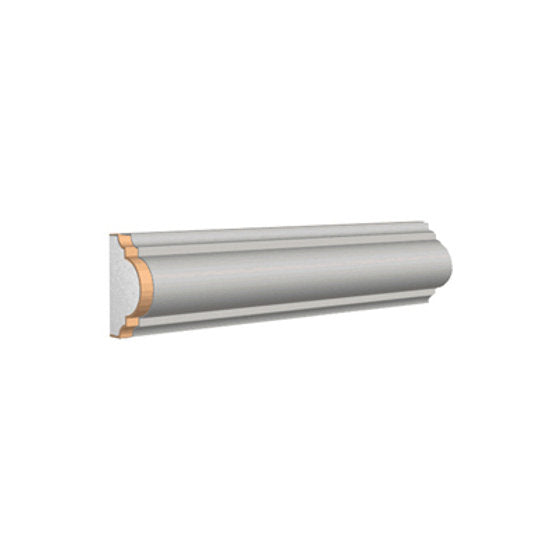

Materials and manufacturing technology

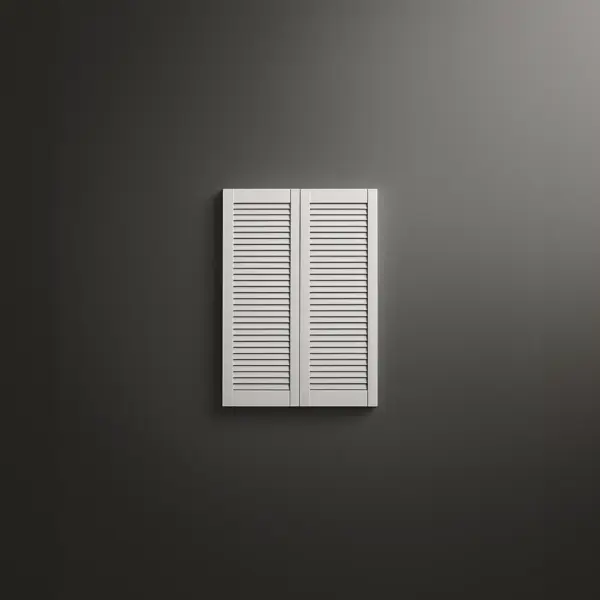

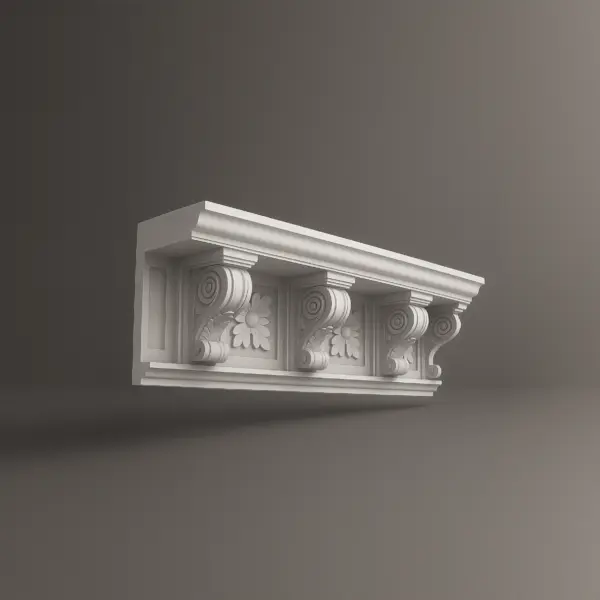

Modern architecture deserves materials that not only perform flawlessly but also inspire confidence. At Decorative Architectural Shapes, we craft our stucco foam trim with the same care a sculptor gives to marble — shaping lightweight, enduring elements that rival the strength and elegance of stone yet move as easily as air.

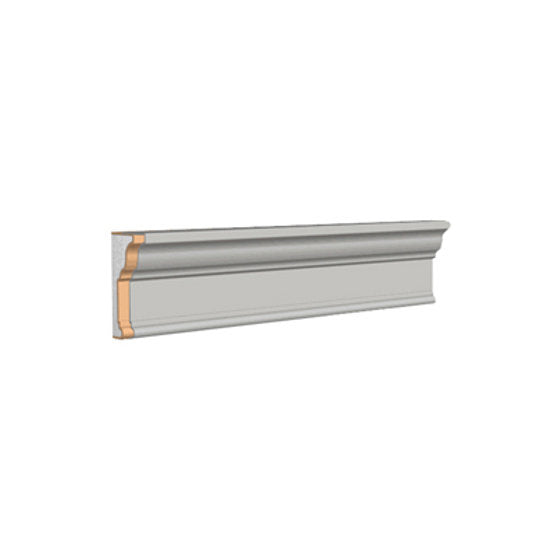

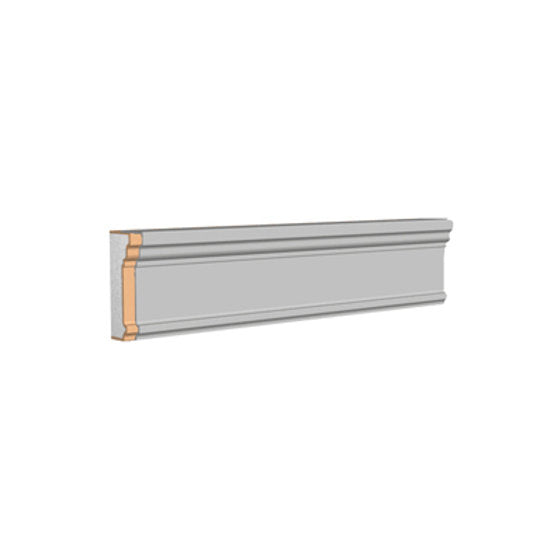

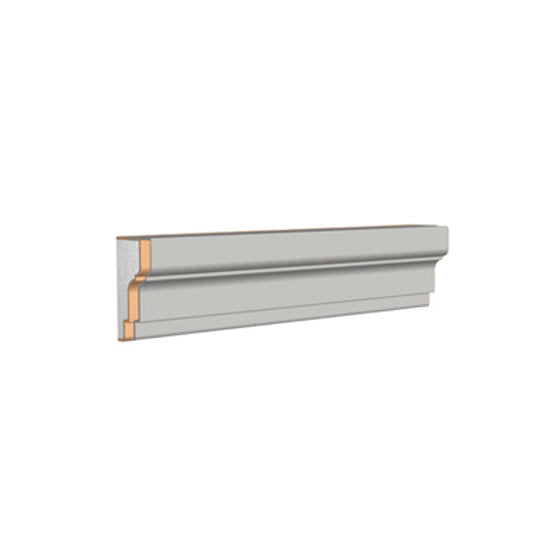

Each piece begins with high-density EPS foam — a material engineered for precision and resilience. Its internal structure acts like a honeycomb, giving it strength without weight. It won’t absorb moisture, it won’t warp in the heat, and it refuses to crack under pressure. The outer protective coating forms a durable shell that locks in color and texture, even under relentless Florida sun or coastal humidity.

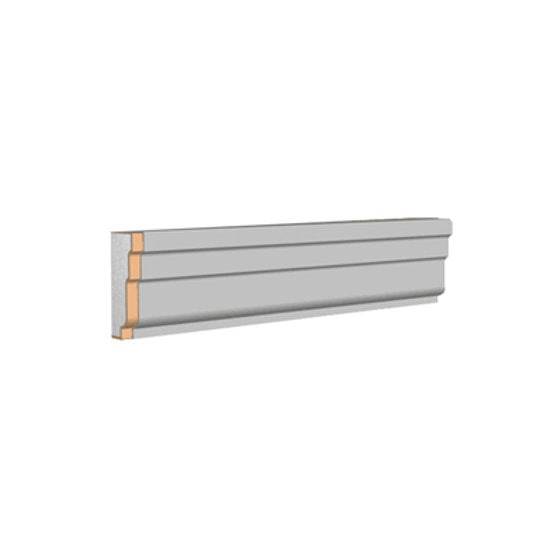

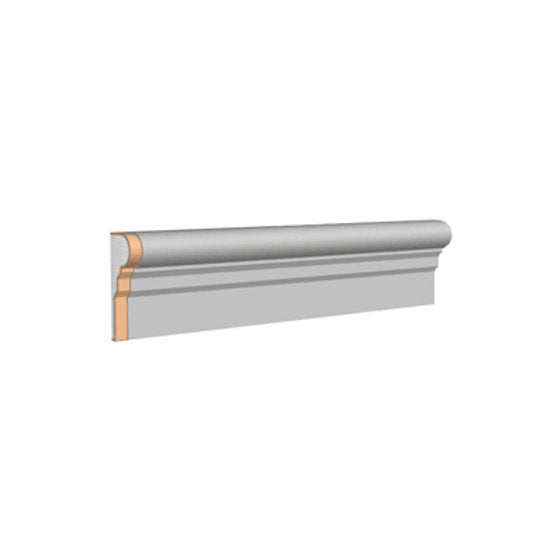

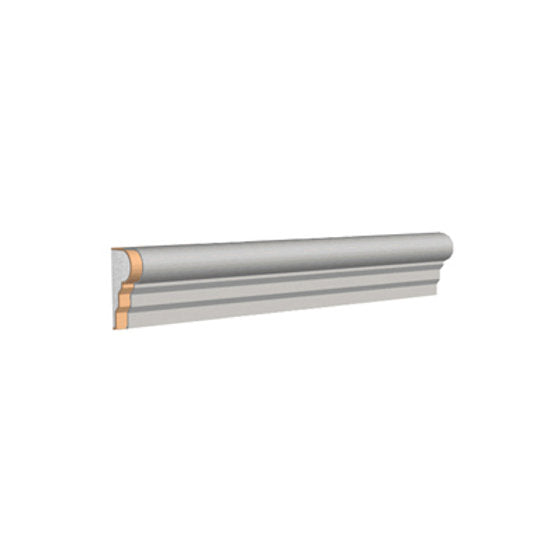

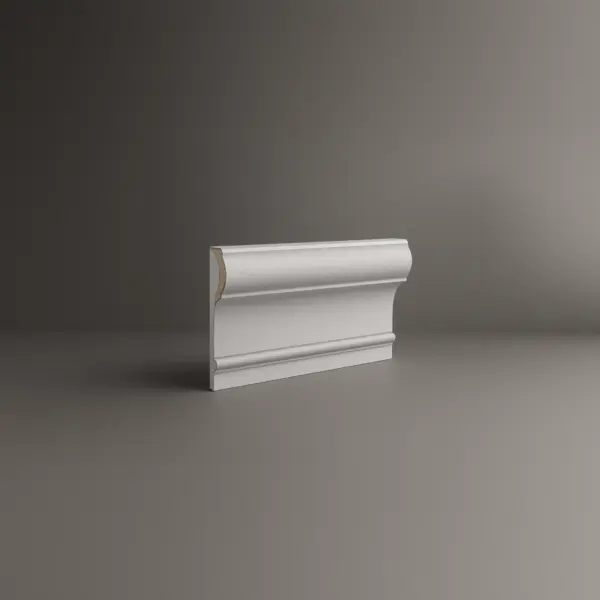

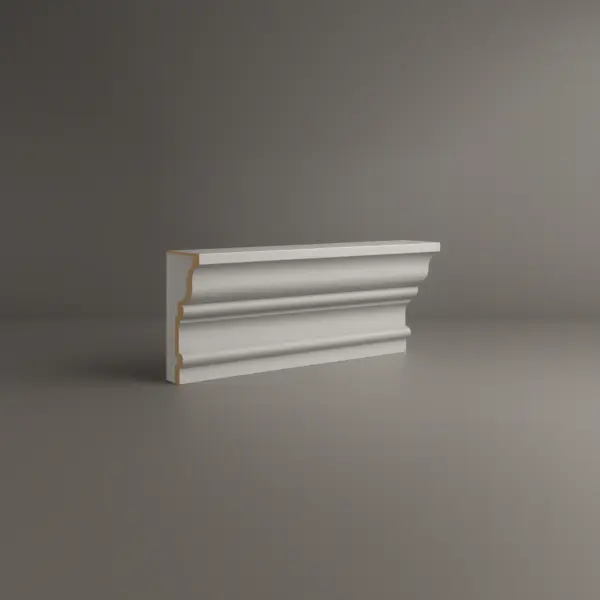

This is where technology meets artistry: CNC precision cutting defines every curve, while our finishing process brings surfaces to life — smooth, tactile, and ready to face decades of weather. The result is a material that looks like carved stone but installs with the ease of wood, proving that beauty and practicality can, in fact, coexist.

Our process combines precision engineering with artistry. Using CNC machinery, we cut every profile — whether a foam trim molding, stucco foam window trim, or architectural molding & trim — to exact specifications. Every product is inspected for geometry, density, and coating consistency.