Logistics, documentation, and delivery: engineered to make your life easier

When deadlines are tight and coordination between trades is complex, logistics can make or break a project. That’s why we treat delivery not as a last-mile service but as part of the engineering process itself. Because all our exterior brackets and corbels are manufactured in the USA, we don’t just organize the shipping of the boxes — we orchestrate the flow of components so they arrive when and how your site needs them.

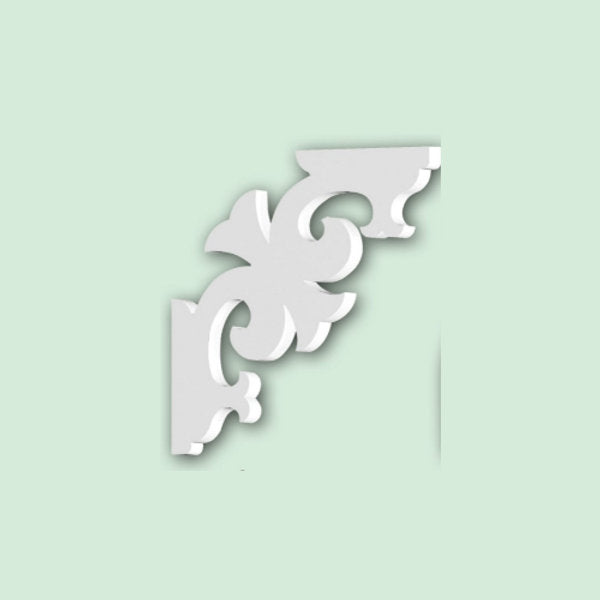

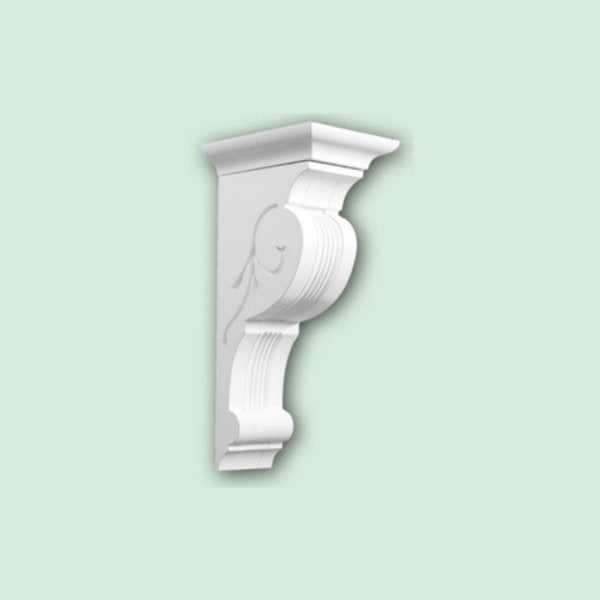

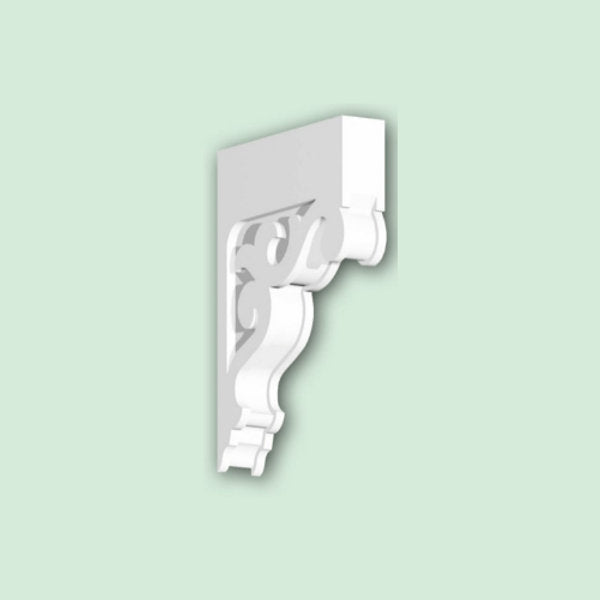

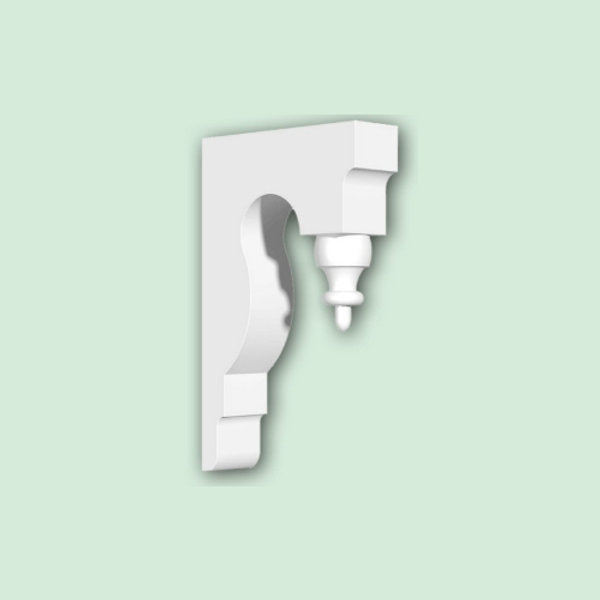

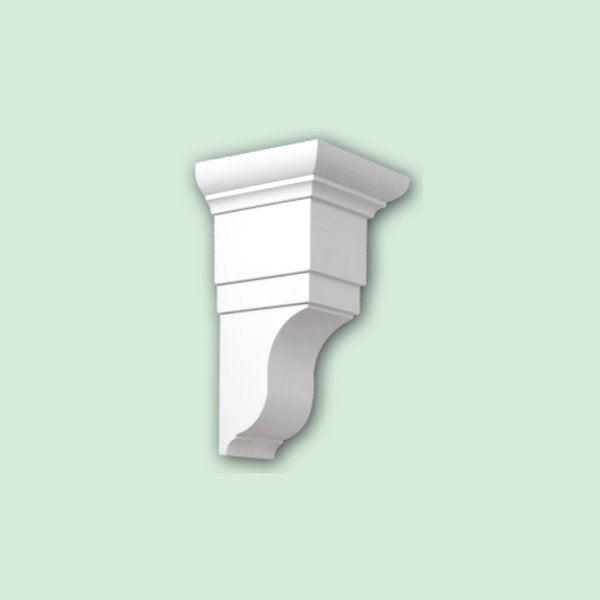

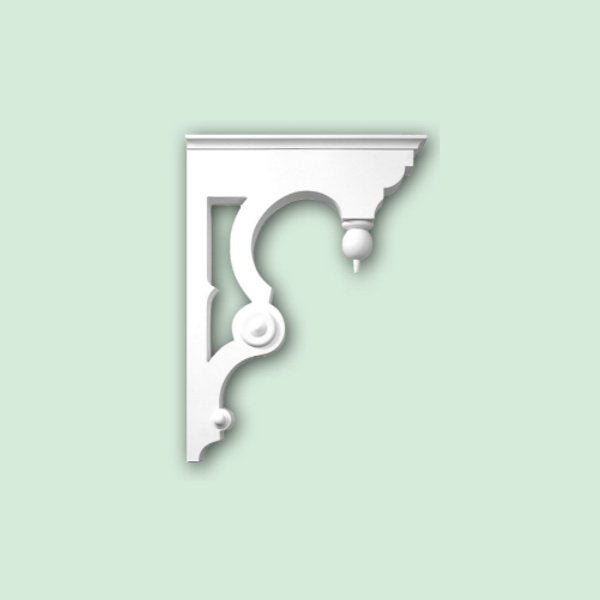

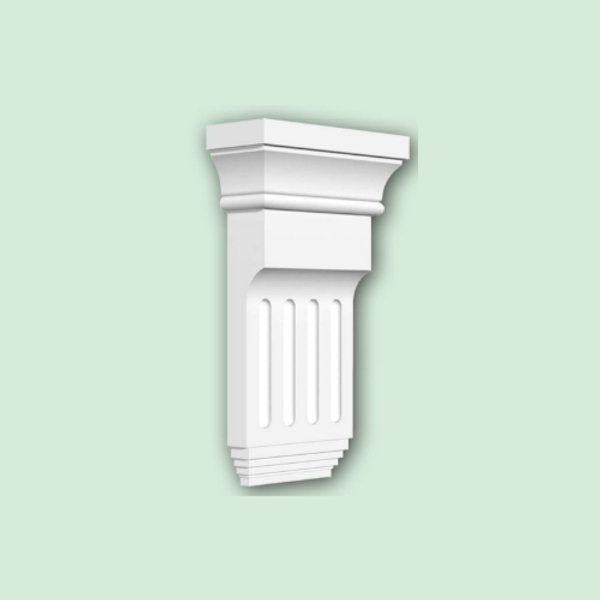

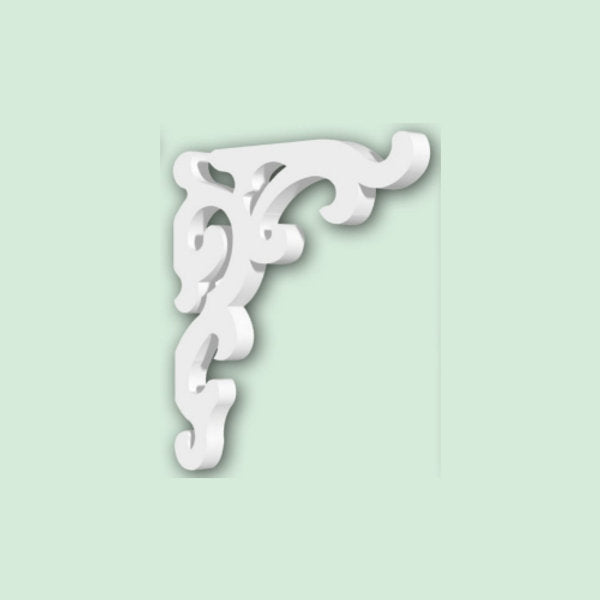

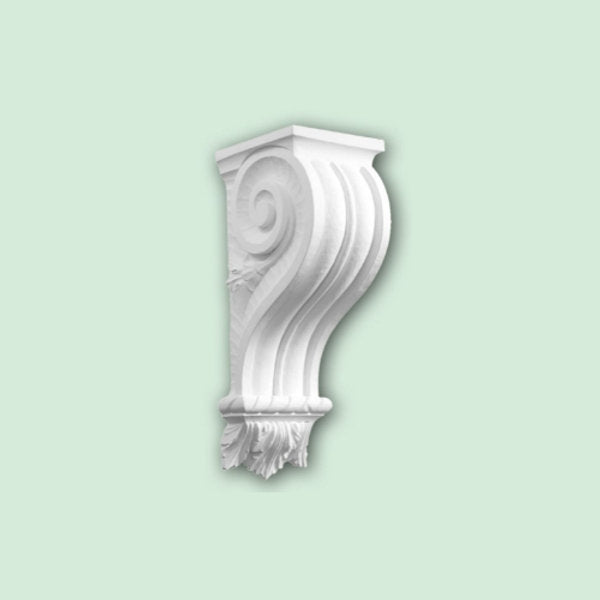

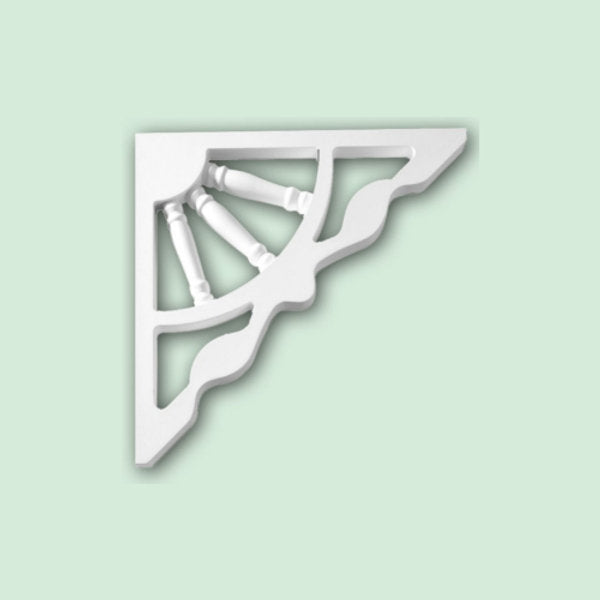

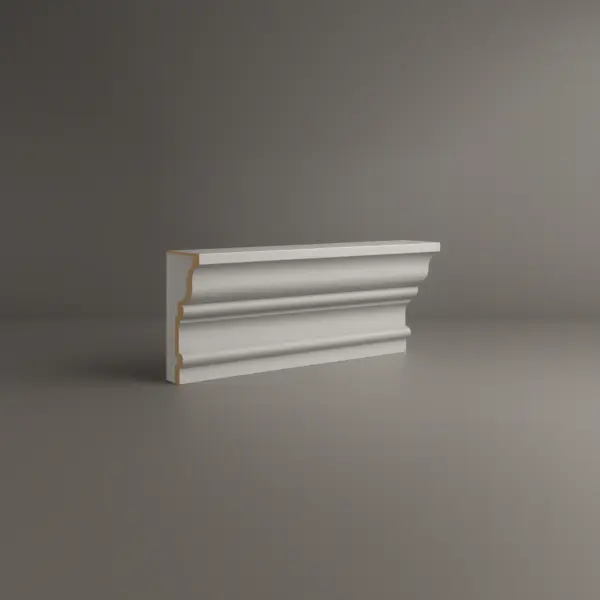

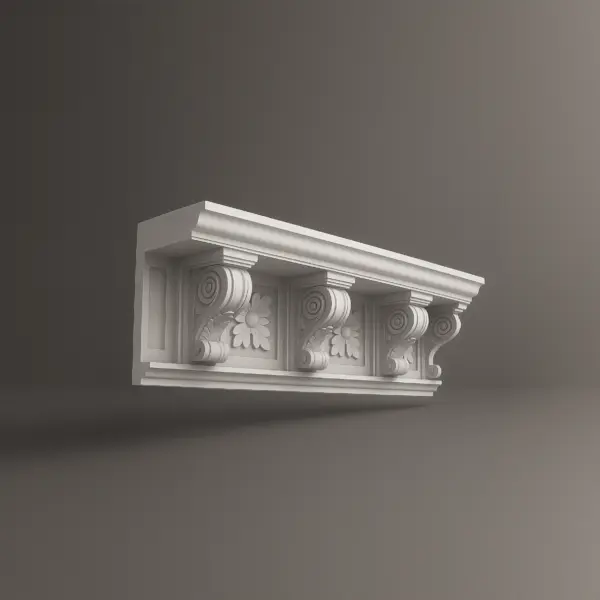

Every piece is packed with the care of a precision instrument. Our corbels and brackets are prefabricated and lightweight, and can be installed by simply gluing them to the wall – so your crew spends hours, not days, on-site. It’s a difference you feel immediately — less scaffolding time, less coordination stress, and a cleaner, faster build.

A good example comes from a large residential complex we supplied in Jacksonville. The developer was facing a tight six-week window before tenant move-ins, and delays from another supplier had already eaten into the schedule. We restructured production into phased shipments, delivering exterior corbels in the order they were needed — roofline components first, then soffit units, then decorative brackets. Because some of the assemblies were pre-mounted on carrier frames, installation time dropped by nearly 40%. What could have been a costly delay turned into an early handover — and a very happy client.

Documentation is treated with the same level of precision. Each delivery includes complete technical packages — detailed drawings, recommended adhesive specs, and even step-by-step installation checklists. The goal is simple: your installers shouldn’t have to guess, adjust, or improvise. Everything they need to do their job quickly and correctly is right there, from the first bracket to the final finish.