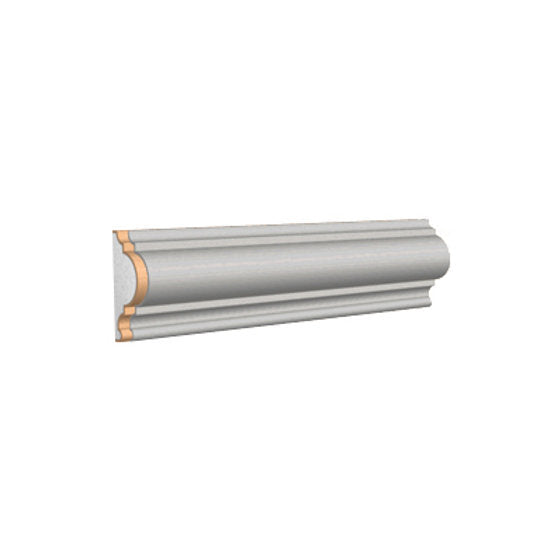

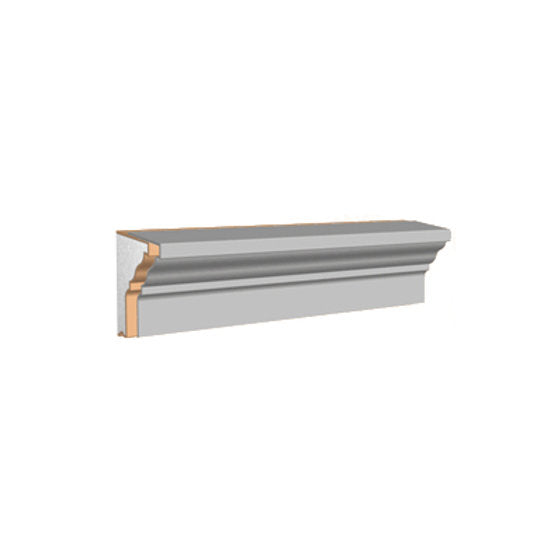

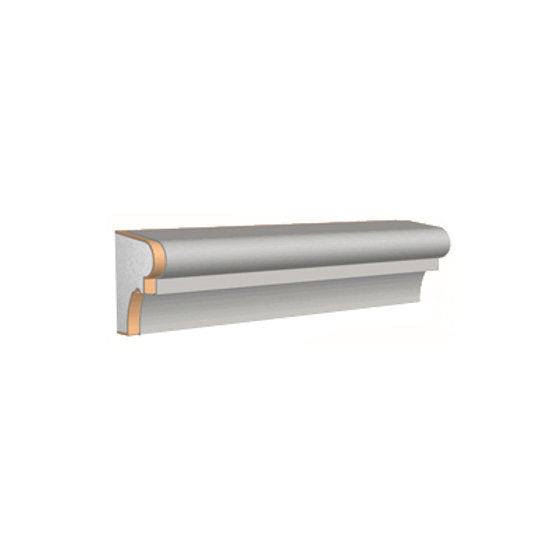

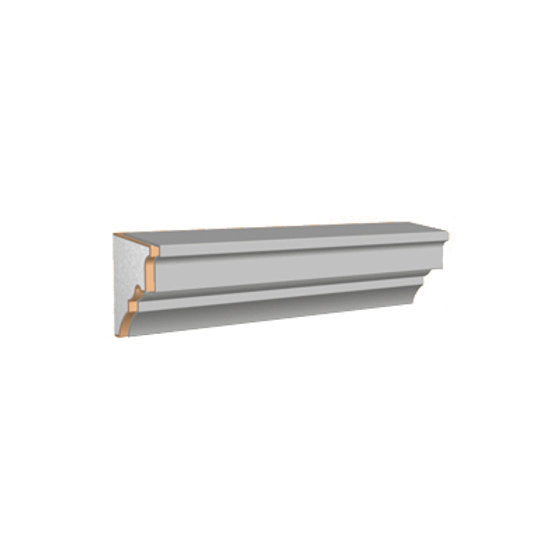

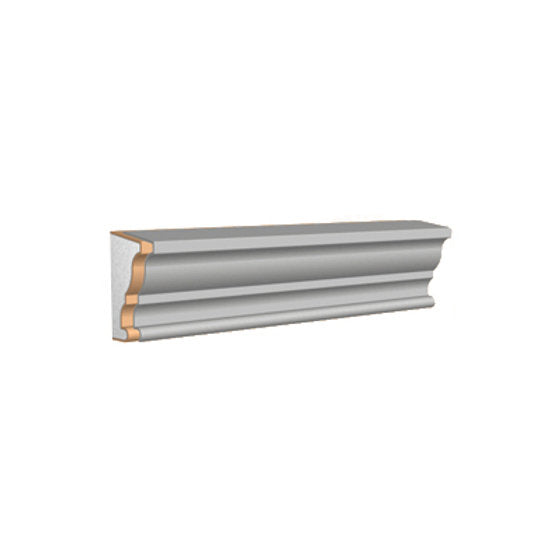

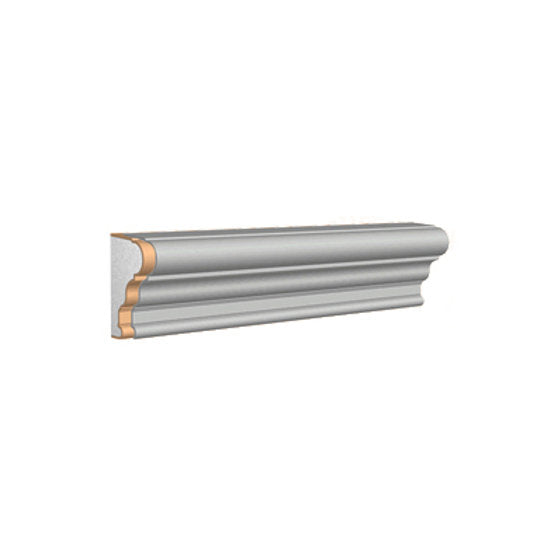

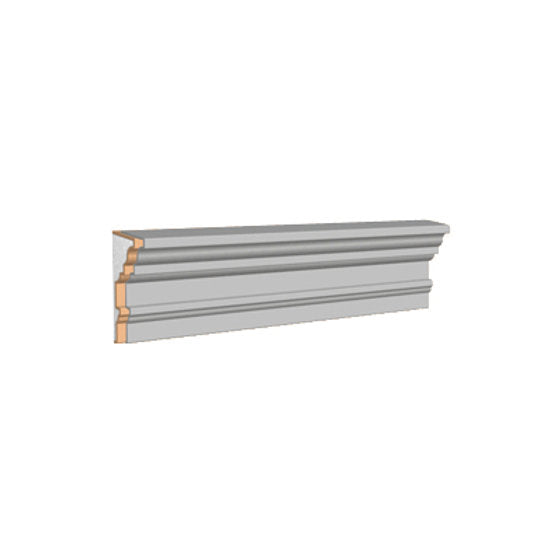

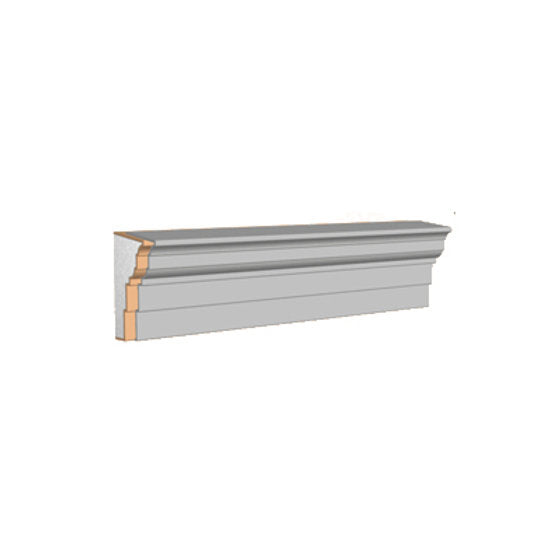

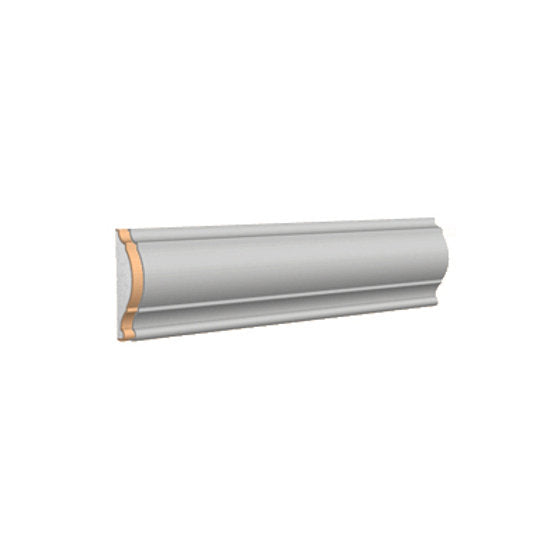

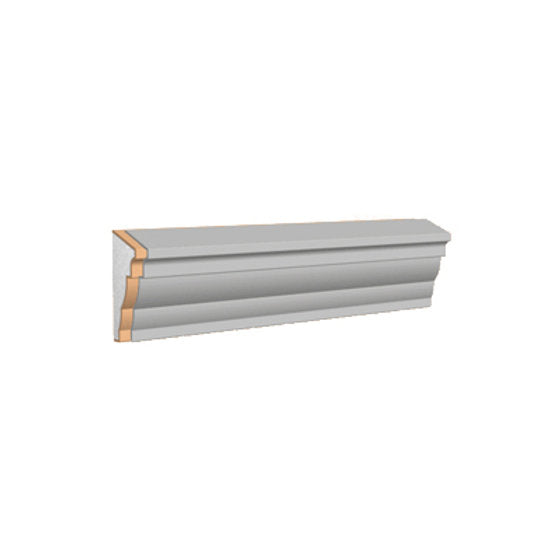

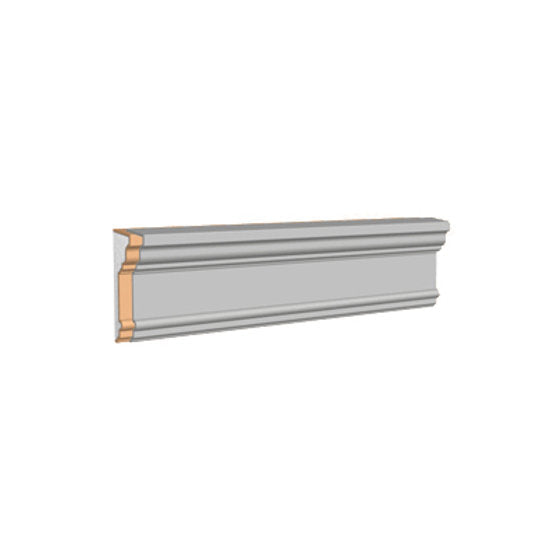

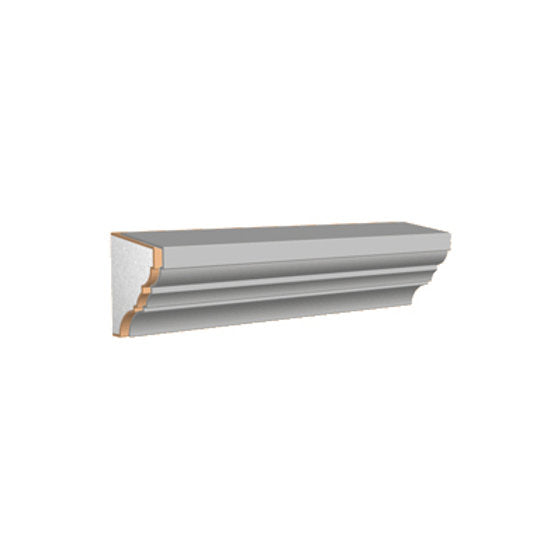

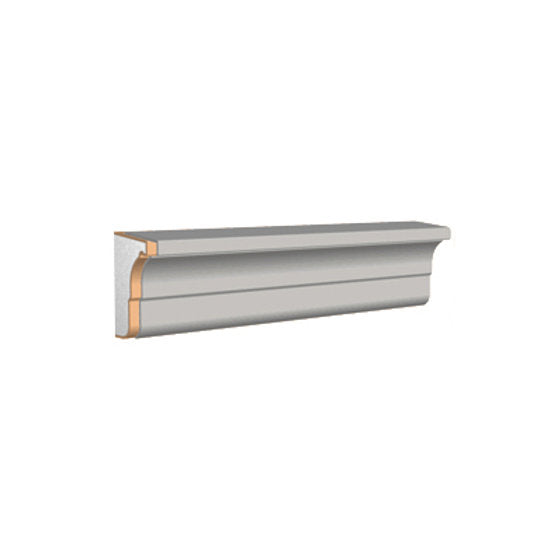

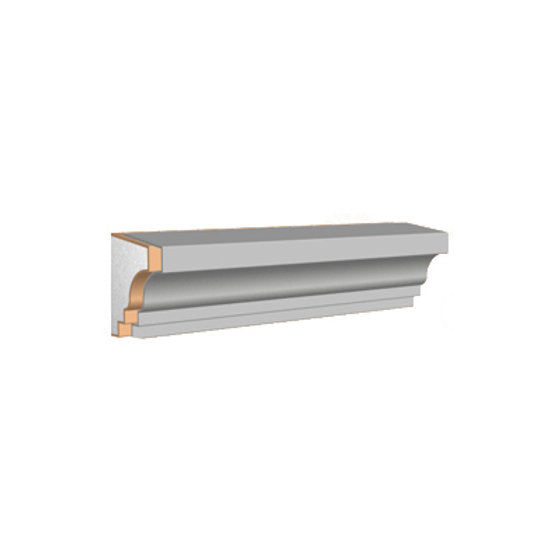

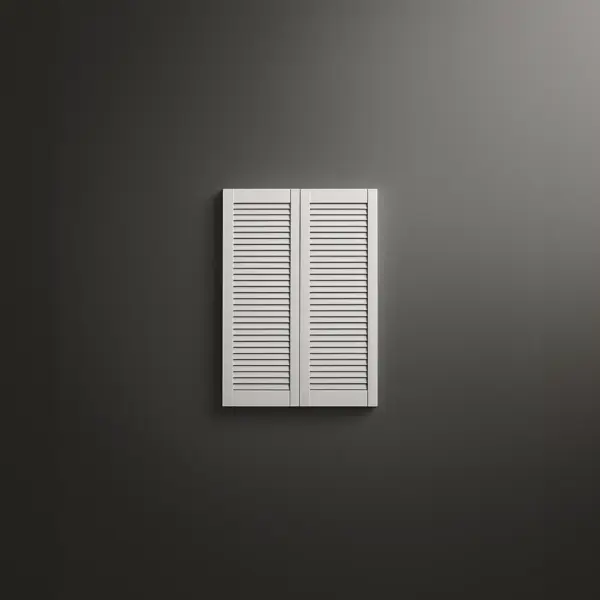

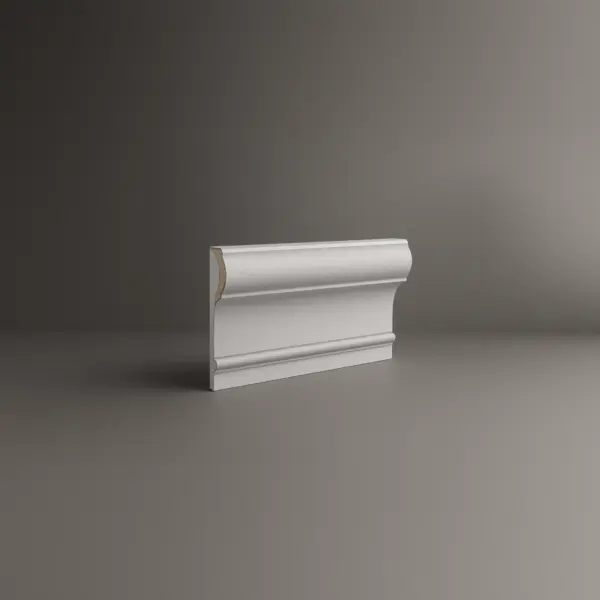

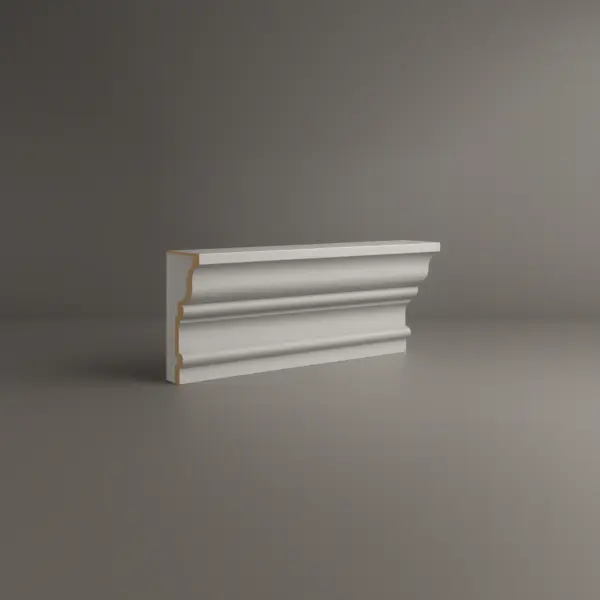

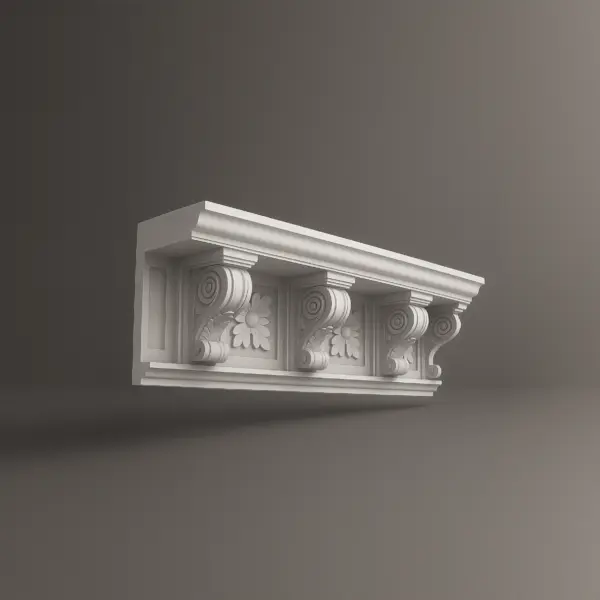

Increase the value of your home and transform ordinary to interesting with over 100 designs, we have something to match every décor style. Lightweight for quick and easy installation

1. CORE OF STRUCTURE IS MOLDED EXPANDED POLYSTYRENE (1#CF).

2. AROMATIC FAST CURE URETHANE, IMPACT RESISTANT, HARD COAT FINISH.

3. TEXTURED FINISHED SURFACE IS 100% AGGREGATED ACRYLIC.

Sharp design clarity and high quality, limitless pattern options

Can be cut, drilled, glued or screwed with common tools

Factory primed and ready for paint or faux finish

Resistant to moisture, insects, and peeling or splitting