Materials and technology: precision at the core

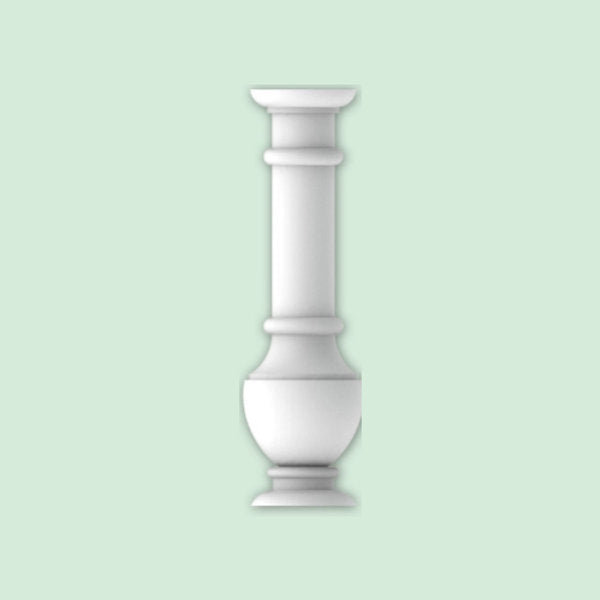

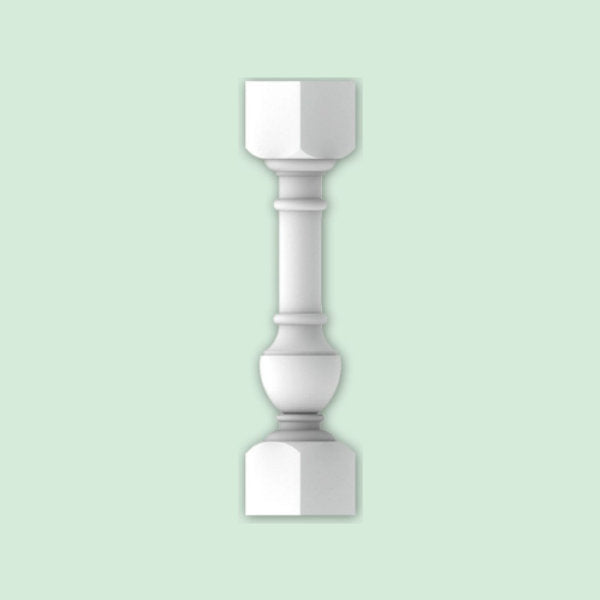

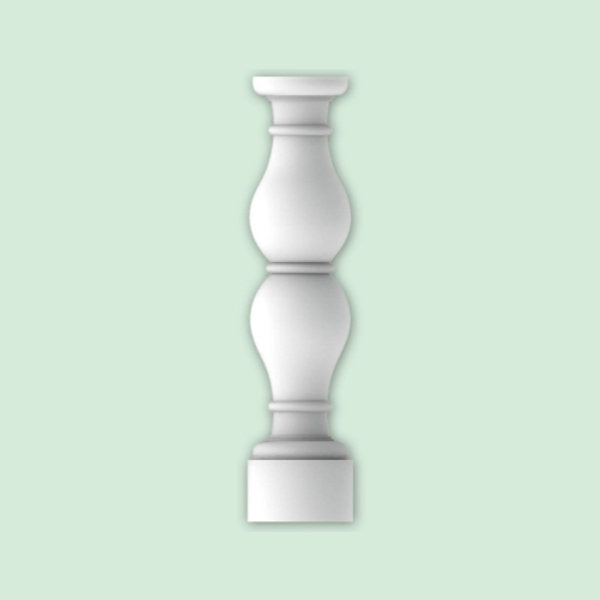

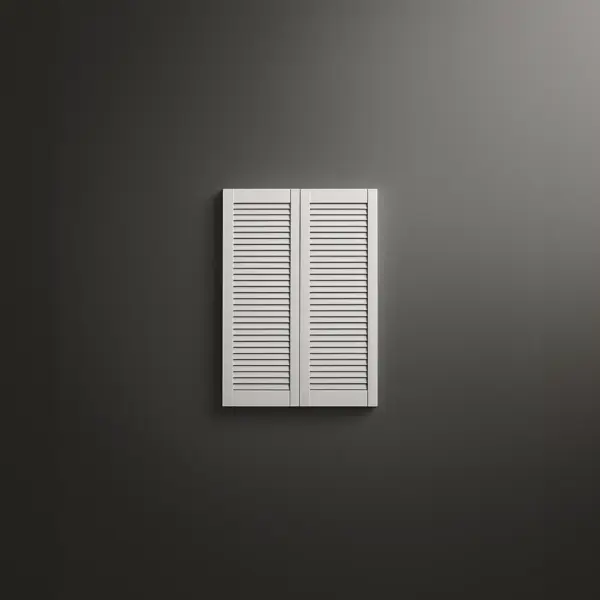

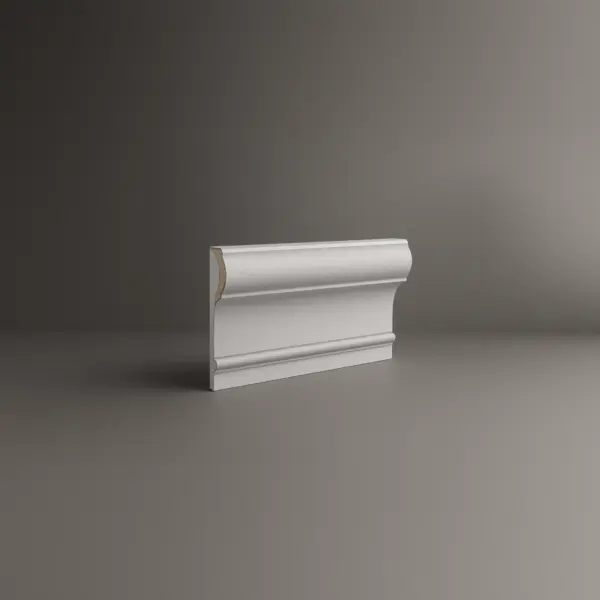

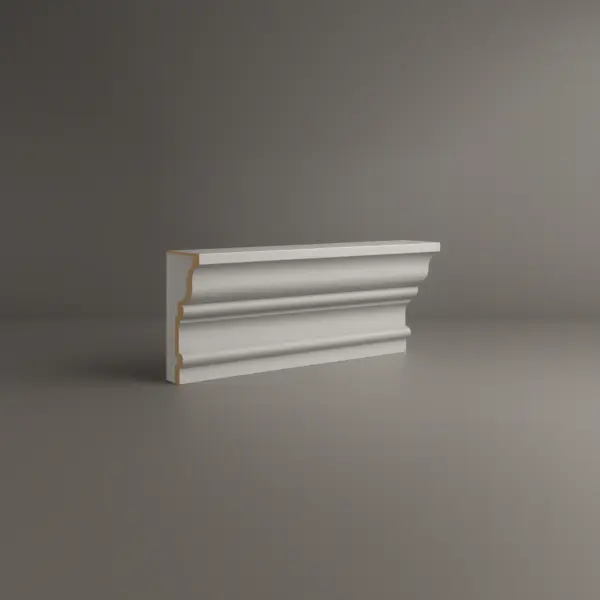

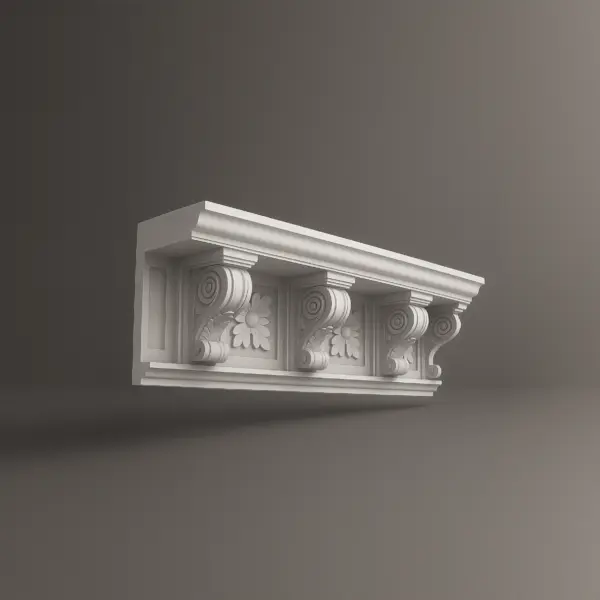

We don’t use metal. We don’t pour concrete. We don’t work with white pine or any other traditional material. Every architectural balustrade, decorative railing panel, and polyurethane baluster we produce is engineered from advanced high-density expanded polystyrene (EPS), coated with a hard aromatic polyurethane layer and finished with an aggregated acrylic texture.

The heart of each system is a molded EPS core. It’s lightweight yet incredibly strong, moisture-resistant, doesn’t warp or rot, and is immune to insect damage — making it ideal for both indoor and outdoor space use.

Over that core, we apply a fast-curing, impact-resistant polyurethane shell. This layer dramatically enhances structural strength, protecting against impact, abrasion, and UV exposure.

The final surface is a 100% aggregated acrylic finish, formulated to withstand harsh weather while offering endless aesthetic possibilities. From the look of carved stone to aged metal or natural wood, we can replicate virtually any texture or finish you imagine. All products arrive prefabricated, so your design intent stays intact down to the last detail.

What does this mean in practice? Our polyurethane balustrades and exterior decorative railing systems:

- Resist moisture, pests, peeling, cracking, and fading.

- Require almost no maintenance and never corrode.

- Deliver consistent geometry and structural stability for decades.

- Arrive installation-ready, reducing labor hours and site work.

On a project in Jacksonville, replacing planned concrete guardrails with polyurethane balustrade systems cut the weight load by 80%. This eliminated the need for slab reinforcement — saving the developer over 18% of the total project budget.