How the manufacturing process actually works

The entire process looks like precise engineering, not just a small, lightweight decorative treatment. Everything begins with architectural data. You provide us with plans, drawings, elevations, BIM files, roof details, as well as diagrams showing the layout of the rafters. Our engineers determine the load paths, how to correctly design the overhang, how to ensure drainage, what the distances to the existing roofing should be, and what the relationships will be between the shed dormer window, its front plane, and the cornices. Only after this does the 3D model begin to be created.

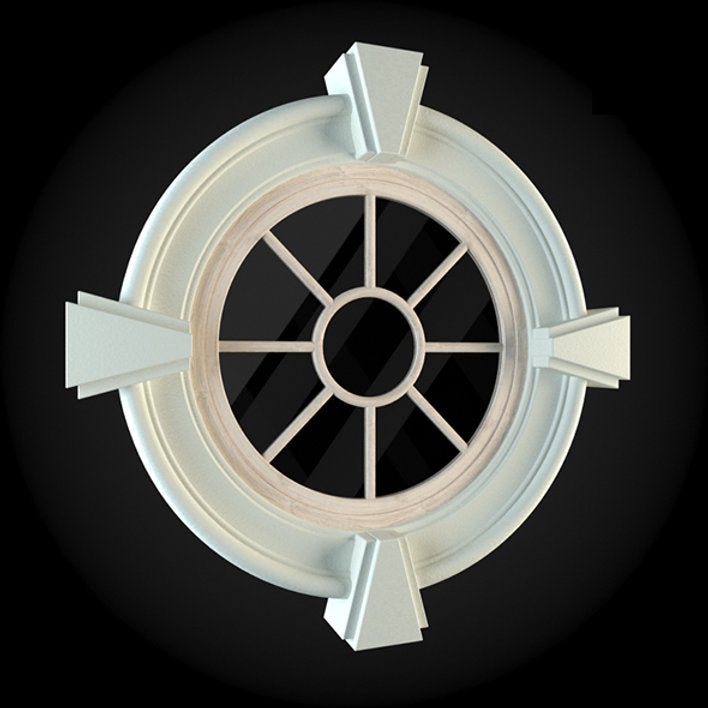

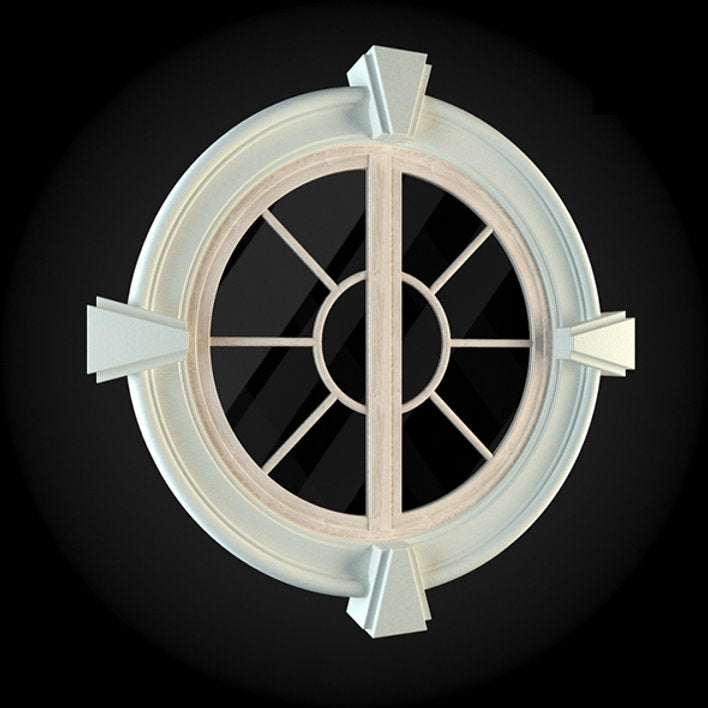

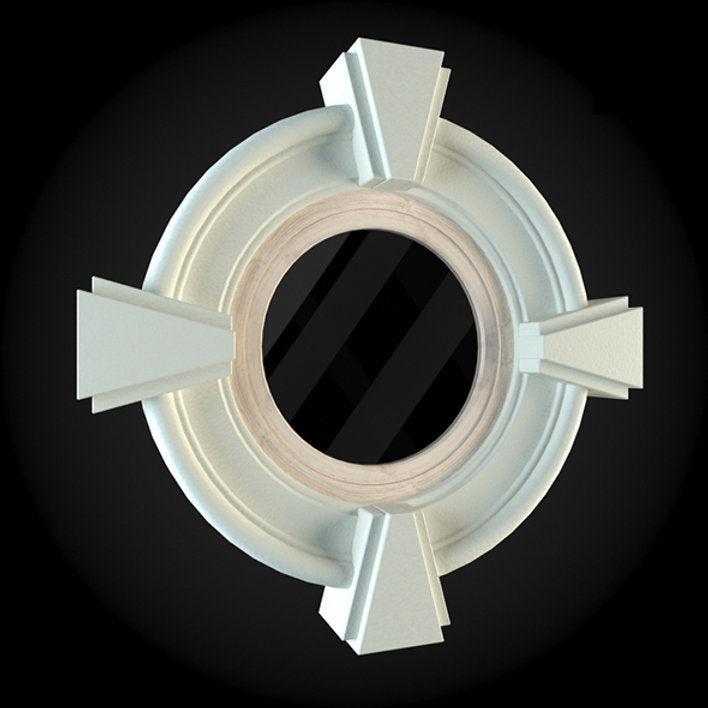

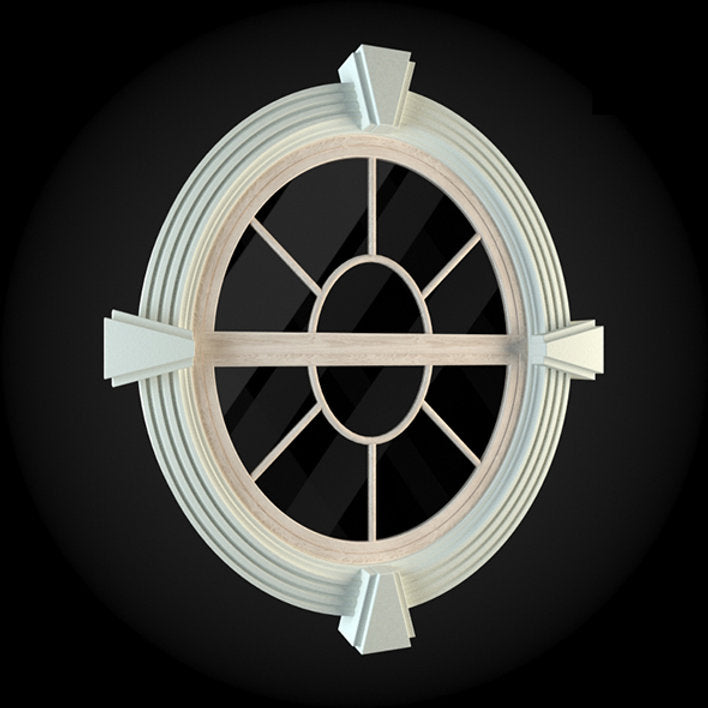

The geometry is not invented or improvised — every part is calibrated, including angles, slopes, and everything else. After the model is approved, CNC programming begins. The foam material is cut with an extremely high level of precision — usually 1/16 inch, and for sensitive joints 1/32 inch. After machining, the foam core is reinforced with a protective shell that is specifically designed to increase impact resistance.

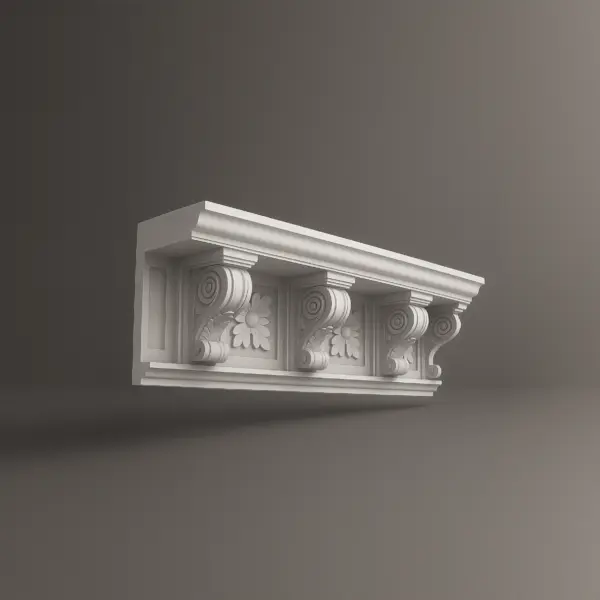

The coating thickness is calculated so that the element remains rigid for large spans, especially if these are large hipped gabled dormer windows. Only after this is the final finishing performed. We apply texture — it can be stone, wood, plaster, and so on. The color is selected according to the samples you provide to us or according to other specifications of your project.

The goal is ultimately to produce an architectural element and form that is fully finished from the moment it arrives and that at the job site it only needs to be installed after being taken out of the crate, without any refinishing or additional work. No priming, no treatments, no cutting — none of this will be required on site. All decorative elements are bonded by us at the factory; this reduces the number of installation errors and speeds up the installation process significantly.

Each element undergoes geometric inspection and coating-quality inspection at the production facility and is delivered with a full set of technical documentation, from drawings to installation instructions. We also provide consultation if any unforeseen questions arise.