About our architectural dormer surrounds

We engineered out the weight, complexity, and on-site labor of traditional dormer construction.

Built as a single, monolithic element

Elegant, weatherproof, and ready for rapid installation—our dormer window architecture is crafted from a high-density, lightweight composite to replicate solid-built structures without the engineering challenges. Perfect for adding character and value to both commercial and residential properties, these surrounds turn a simple roof penetration into a powerful architectural statement.

Each dormer surround is a precision-fabricated, monolithic unit designed for a perfect fit:

- Integrated Body: The main structure is crafted as one piece, eliminating seams and joints where water and pests can infiltrate.

- Crisp Details: The trim, sills, and any decorative elements are integral to the design, ensuring clean, sharp lines that traditional methods can’t easily match.

- Ready-to-Install: The unit arrives on-site fully finished, ready to be lifted and secured in place by a small crew, transforming the installation from a multi-day framing job into a simple, efficient process.

Get a prefabricated system that installs with absolute precision.

The science behind architectural freedom

Our architectural dormer surrounds are built from an advanced composite of materials engineered for a century of performance. At the core is a structural, high-density Expanded Polystyrene (EPS) foam, precision-cut with CNC technology for flawless geometry that matches your CAD files to the millimeter.

This core is then fully encapsulated in our signature polyurea hard coat—a high-pressure, spray-applied elastomer that creates a seamless, waterproof, and impact-resistant shell. This isn’t just a coating; it’s armor. It transforms the lightweight foam into a monolithic element with incredible structural integrity.

The exterior is an integrated, architectural-grade finish, ready for paint. This advanced construction makes our decorative dormer windows robust, elegant, and engineered to last 80-100 years with virtually zero maintenance.

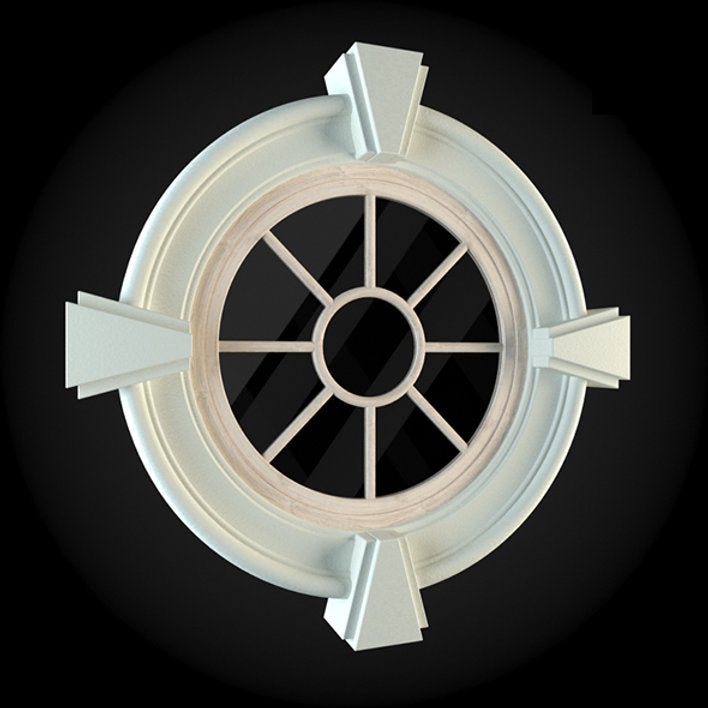

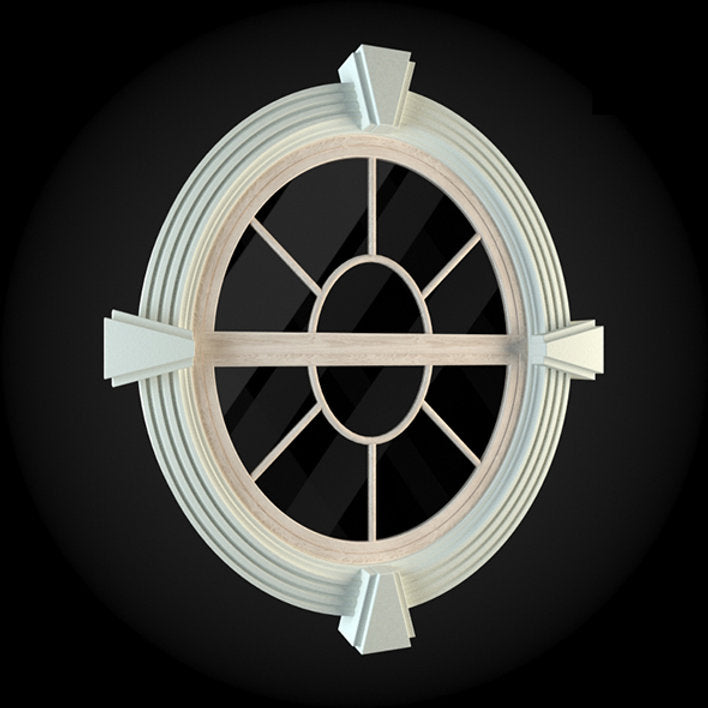

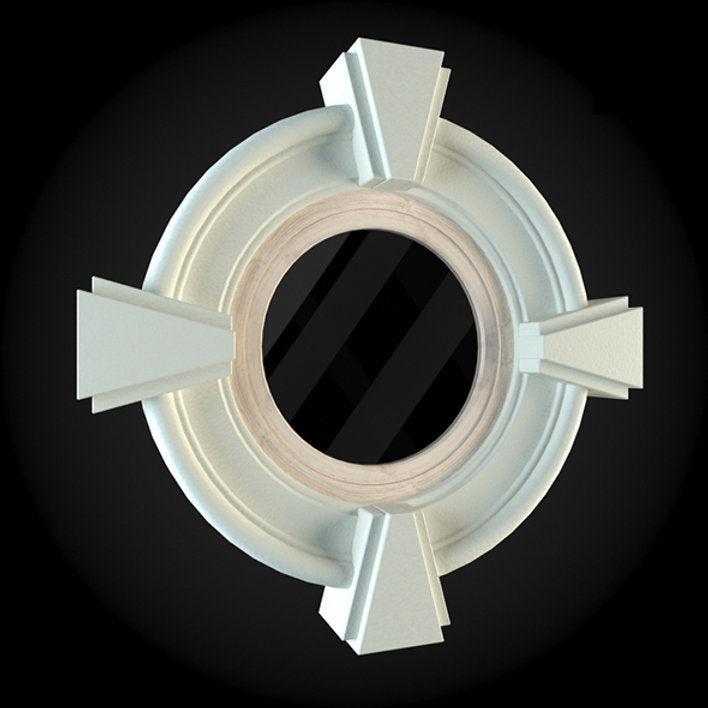

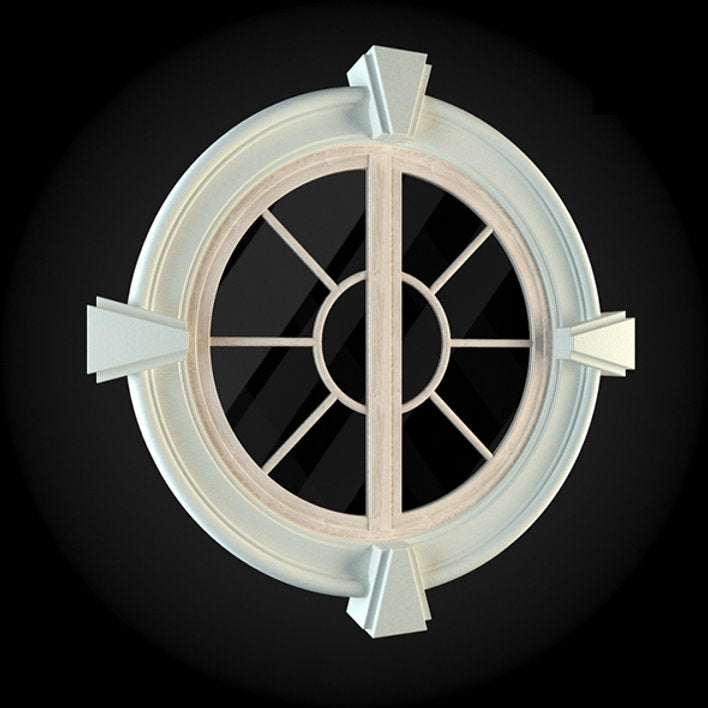

Architectural dormer surround collection

EPS dormer surrounds vs. traditional construction:

the Decorative Architectural Shapes advantages

Stop wrestling with heavy, high-maintenance materials that dictate your design. Choose lightweight, durable, and fully custom dormer architecture—built to last, made in the USA.

Demands expensive, over-engineered roof structures and adds significant project risk.

On-site stick framing is slow, weather-dependent, and creates a logistical nightmare of coordinating multiple trades.

Wood rots and warps. Concrete cracks. Both demand constant, costly upkeep and repairs.

You're limited to basic shapes. Complex designs are either impossible or will destroy your budget.

High upfront costs for labor and materials, followed by a continuous drain from maintenance and repairs.

Eliminates the need for costly roof reinforcement and complex structural engineering.

Arrives as a single, finished unit. Installs with a small crew, crushing timelines and labor budgets.

Impervious to rot, pests, and water. A 100-year, maintenance-free lifespan.

If you can design it in CAD, we can build it. Achieve any curve, angle, or detail without limitation.

Massive savings on labor, engineering, and equipment. Zero maintenance costs mean it's the smarter investment from day one.

Сustom architectural dormer windows surround

How to order your custom dormer surrounds

From your initial sketch to job site delivery—our process is transparent, fast, and engineered for your success.

It all begins with a deep dive into your project. We work as your technical partner to transform creative intent into a solid, actionable plan.

- Analyze Your Inputs: We review your architectural plans, CAD files, sketches, and inspirational images to understand your design from every angle.

- Define the Scope: In a collaborative consultation, we discuss the project’s aesthetic goals, site conditions, and technical requirements to ensure a perfect fit.

- Establish a Technical Blueprint: We finalize all specifications, from dimensions to finish textures, creating a clear roadmap for fabrication that aligns perfectly with your vision.

We bridge the gap between concept and cost, providing you with the clarity and confidence to move forward.

- Receive a Detailed 3D Visualization: We create and send you a precise 3D model, allowing you to see exactly how your custom architectural elements will look before production begins.

- Get a Transparent, Itemized Proposal: You receive a clear, comprehensive quote with no hidden fees. We believe in total transparency, so you know exactly what you’re investing in.

- Maintain Complete Control for Final Approval: We don’t proceed until you are 100% satisfied. You have the final say on the design and budget before we move to the next stage.

This is where your approved design becomes a physical reality, crafted with an obsessive focus on quality in our 45,000 sq. ft. workshop.

- Execute with Robotic Accuracy: Our state-of-the-art CNC hot-wire machines carve your architectural elements with flawless precision, matching your approved 3D models to the exact specification.

- Armor for a Century of Performance: Our skilled artisans apply our signature Polyurea hard coat, creating a seamless, impact-resistant, and weatherproof shell designed for decades of durability.

- Verify Through Rigorous Quality Control: Every single piece undergoes a multi-point inspection to ensure it meets our exact standards for shape, finish, and structural integrity.

Our commitment extends all the way to your job site, ensuring a smooth and successful installation.

- Protect with Secure, Custom Crating: We build specialized shipping crates for every project, guaranteeing your elements arrive in pristine, ready-to-install condition.

- Streamline Your Installation: Your pieces are delivered pre-assembled and lightweight, designed to slash on-site labor time and eliminate the need for heavy machinery.

- Support Your Crew to the Finish Line: We provide detailed installation guides and offer live Zoom support to answer your team’s questions, guaranteeing a perfect final fit.

It all begins with a deep dive into your project. We work as your technical partner to translate creative intent into a solid, actionable plan.

- Analyze Your Inputs: We review your architectural plans, CAD files, sketches, and inspirational images to understand your design from every angle.

- Define the Scope: In a collaborative consultation, we discuss the project’s aesthetic goals, site conditions, and technical requirements to ensure a perfect fit.

- Establish a Technical Blueprint: We finalize all specifications, from dimensions to finish textures, creating a clear roadmap for fabrication that aligns perfectly with your vision.

We bridge the gap between concept and cost, providing you with the clarity and confidence to move forward.

- Receive a Detailed 3D Visualization: We create and send you a precise 3D model, allowing you to see exactly how your custom architectural elements will look before production begins.

- Get a Transparent, Itemized Proposal: You receive a clear, comprehensive quote with no hidden fees. We believe in total transparency, so you know exactly what you’re investing in.

- Maintain Complete Control for Final Approval: We don’t proceed until you are 100% satisfied. You have the final say on the design and budget before we move to the next stage.

This is where your approved design becomes a physical reality, crafted with an obsessive focus on quality in our 45,000 sq. ft. workshop.

- Execute with Robotic Accuracy: Our state-of-the-art CNC hot-wire machines carve your decorative architectural shapes with flawless precision, matching your approved 3D model to the millimeter.

- Armor for a Century of Performance: Our skilled artisans apply our signature Polyurea hard coat, creating a seamless, impact-resistant, and weatherproof shell designed for decades of durability.

- Verify Through Rigorous Quality Control: Every single piece undergoes a multi-point inspection to ensure it meets our exacting standards for form, finish, and structural integrity.

Our commitment extends all the way to your job site, ensuring a smooth and successful installation.

- Protect with Secure, Custom Crating: We build custom shipping crates for your elements, ensuring they arrive on-site in pristine, ready-to-install condition.

- Streamline Your Installation: Your pieces are delivered pre-assembled and lightweight, designed to slash on-site labor time and eliminate the need for heavy machinery.

- Support Your Crew to the Finish Line: We provide detailed installation guides and offer live Zoom support to answer your team’s questions, guaranteeing a perfect final fit.

Our project gallery

Engineered solutions for every vision

Whether you design the vision, manage the budget, or build the reality, we’re engineered to make your project succeed.

We provide stunning, high-value architectural details that create instant curb appeal and help sell properties faster. Our prefabricated roof dormer windows ensure a consistent, high-quality look across entire communities with installation times that keep your project on schedule.

Realize your most ambitious dormer architecture without compromise. We fabricate custom solutions to your exact CAD specifications, from massive, statement-making large dormer windows to subtle side dormer windows that add character. We provide the technical partnership you need to build what you envision.

Transform a standard building into a landmark. Our dormer surrounds are ideal for hotels, corporate headquarters, and retail centers, adding a look of permanence and sophistication with zero long-term maintenance burden.

Create the ultimate architectural statement for your custom home. Whether you’re adding light with attic dormer windows or crafting a unique facade, our systems provide the bespoke quality and elegance your property deserves.

Before and after

Discover our workHow our dormers elevate your architectural value

A dormer isn’t just a window—it’s the face of your building. It’s the first and last architectural detail that defines a property’s character and communicates its value. A well-engineered dormer surround from Decorative Architectural Shapes instantly elevates your project from standard construction to a landmark design, setting you apart before anyone even steps inside.

- Curb Appeal that Commands a PremiumA powerful, monolithic dormer adds an immediate sense of permanence and high-end quality. It demonstrates an investment in superior design and detail, which builds trust with buyers and tenants alike. This isn't just an upgrade; it's an architectural signature that justifies a higher property valuation and attracts a more discerning clientele.

- A Zero-Maintenance Asset, Not a LiabilityForget the endless cycle of scraping, painting, and repairing rotting wood or cracked concrete. Our dormer surrounds are engineered as a single, impenetrable unit that withstands harsh weather, UV rays, and time—staying pristine year after year with zero maintenance. This incredibly low total cost of ownership is a smart, strategic investment for any commercial or residential property.

- Custom Design for a Unique IdentityYour building should be an extension of your brand or vision. With unlimited design potential—from sleek, minimalist profiles to intricate historical replications—our architectural dormers can be tailored to align perfectly with your project's unique architectural style. Stop choosing from a catalog; let's build the exact feature that makes your property unforgettable.

Client testimonials

From your first idea to the final installation — our process is clear, fast, and designed to make every detail simple.

FAQ

What technical documents are included?

Our architectural dormer windows surrounds are supplied with a complete set of technical documentation, starting with drawings, as well as installation diagrams, assembly and installation instructions, roof-tie details, hardware specifications, and additional guidance when working with non-standard architectural components. If needed, we also provide standards and quality specifications for the manufactured products in accordance with U.S. building and fire-safety codes.

Are these compatible with different roof materials?

Yes. We design connection details for metal panels, shingles and tile roofs, ensuring proper waterproofing and clean integration.

Are foam dormers suitable for modern minimalist architecture?

Absolutely. Foam allows razor-sharp edges and seamless planes. A project near Orlando featured five ultra-minimalist modern shed dormer windows that would have been difficult in heavier materials.

Are all elements delivered painted?

Always. Every exterior dormer windows surrounds arrives fully finished, requiring no priming, sanding or coating on site.

How fast is installation?

Usually about 165–190 linear feet in four workdays. On a particularly tight downtown site, an entire run was installed with just a small crew and no heavy equipment — and still finished ahead of schedule.

Will it feel quieter next to a busy road?

Absolutely. Most people notice the difference the first evening. The shell reflects harsh noise while the foam core absorbs the rest. At a project near a Miami expressway, the change was dramatic enough that residents started using their outdoor space again.

Can you match our façade color exactly?

Yes — we’re obsessive about that. Foam takes acrylic with precision, and we routinely achieve perfect visual matches. A historic property in Savannah once had us match an aged brick tone, and even the neighbors assumed the new wall was original masonry.

What if we have a big grade change?

No problem. Foam follows contours far more easily than concrete or masonry. Instead of awkward steps, we can create smooth transitions that maintain visual calm and proper drainage.

Will a white finish last in coastal weather?

It will if the system is specified correctly. With the right coating and finish, walls along the Gulf Coast have stayed chalk-free and color-true for years. Occasional rinsing is usually all the maintenance required.

Are foam panels strong enough for high winds?

Yes. When everything is engineered thoughtfully — from precise anchor spacing to slightly shortened modules in the most exposed spots — the fence doesn’t behave like a fragile structure, but like a seasoned sailor standing firm on deck in the middle of a storm. Even hurricane-level coastal winds don’t faze it: it doesn’t shift a millimeter, doesn’t crack, and never gives in to the elements. At one property near Daytona Beach, the fence looked as if it had been installed yesterday, even after an entire storm season — perfectly straight, steady, and untouched. It’s more than just strength; it’s a quiet confidence you can feel when you look at it, as if the architecture itself is saying, “I’m right where I belong — and I’m not going anywhere.”

& specification catalog

Get the definitive guide to our custom decorative architectural foam shapes. This free catalog is packed with hundreds of design profiles, detailed technical specifications, and real-world project applications.

Have a project in mind?

Our dedicated specialists are ready to collaborate with you, turning your concept into a detailed plan with a transparent budget. Let’s bring your vision to life!

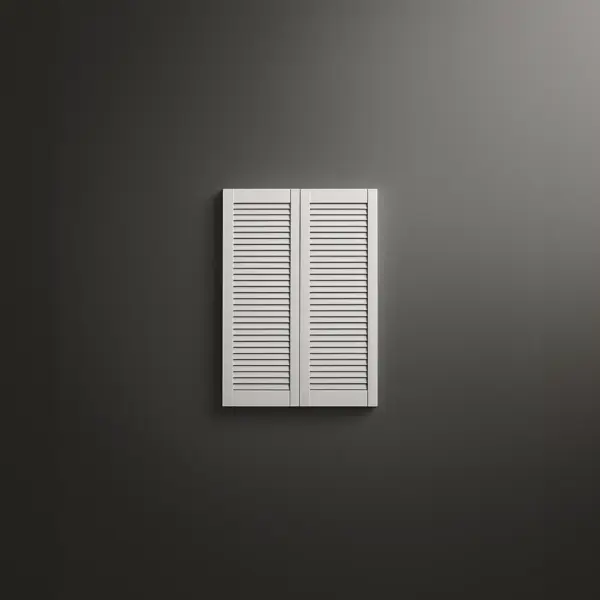

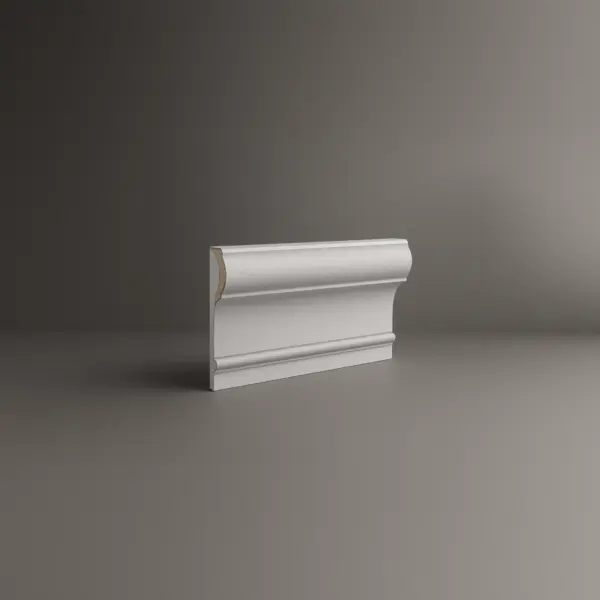

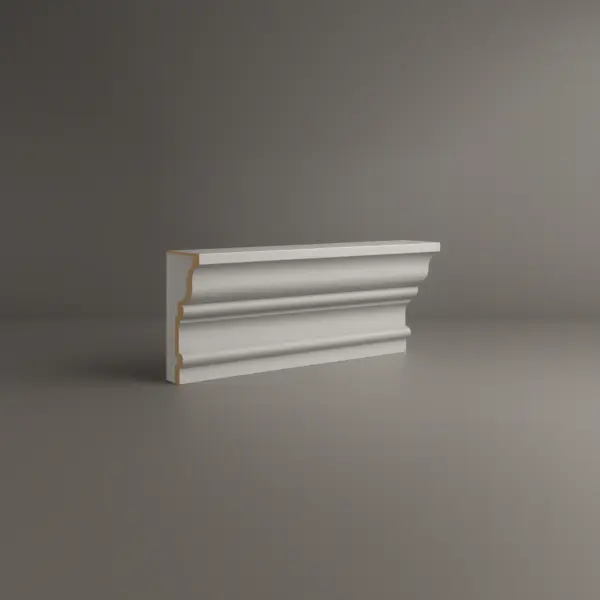

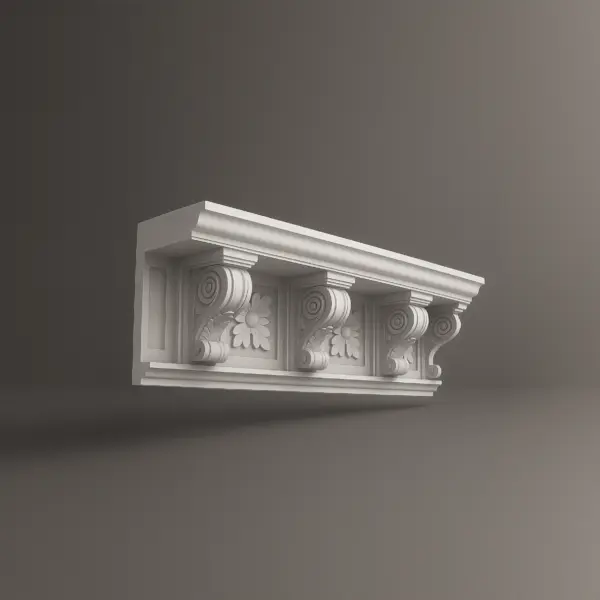

More architectural shapes

We provide architects, builders, and homeowners with turnkey decorative elements that transform any project — fast, easy, and cost-effective.

Architctural dormer window surrounds

In the architecture of a modern building, there are details and elements that don’t scream for attention.

They aren’t meant to be the star of the façade or the main visual centerpiece, yet they play a crucial role in forming the building’s integrity and giving it a distinct character. Architectural dormer windows surrounds belong to this category.

Made from high-density foam, these surrounds allow architects and engineers to achieve precise structural results because they do not overload the building’s walls or roof system. They install predictably, they make the building look complete and cohesive, and they harmonize the overall appearance of the structure. At the same time, they can be installed quickly and without unnecessary complications.

Anyone who works with faсades — whether an architect, installer or designer — knows that when elegant flat roof dormer windows are included in the drawings, they almost always bring a set of additional challenges. Weight calculations begin to rise, roofing contractors become concerned about overloading the rafters, and decorative solutions made from heavier materials often become impossible.

Installers also frequently face on-site issues: trimming, sanding, or adjusting details that don’t quite match the roof geometry. With dormer windows, this happens especially often because their shapes tend to be more complex and non-standard.

This is exactly why Architectural dormer window surrounds are an excellent alternative to natural materials. They simplify workflows, solve practical engineering tasks, and provide the visual result the design requires. Additionally, the coatings and finishes we apply to each architectural element ensure long-term performance. The colors do not fade, the finish remains stable for many years — a durability we confidently support with a 20-year warranty.

We’ve been manufacturing architectural foam elements for 25 years, and we fully understand how to keep your project’s budget optimal without compromising on the quality or visual appearance of the architectural components.

A decorative dormer windows surround made from architectural foam allows you to solve both practical tasks and the aesthetic harmonization of the façade. And since we fabricate these elements fully finished — painted, protected with a durable coating, and ready for installation — all that remains is to place them on the building.

Every project is delivered with full technical documentation, installation instructions, assembly guidelines, and, if required, we provide individual consultation and support for each project.

Dormer windows definition and architectural value

A basic dormer window definition describes a vertical opening built into the slope of a roof. But the architectural value goes far deeper.

Dormer windows (shed dormer, gabled dormer or sloped dormer):

- introduce rhythm and verticality to the roof plane;

- visually “lift” the mass of the building without requiring additional floors;

- give the façade a recognizable silhouette that supports the project’s branding;

- dramatically improve dormer windows inside by creating usable depth, niches, and natural-light pockets.

When we design dormer style windows from foam, we treat them as compositional anchors. Their proportion, spacing and profile are integrated with cornices, roof pitches and façade geometry. It’s not an “add-on”; it’s an architectural statement.

A deeper look at the history of dormer window architecture

Dormer architecture appeared long before modern building technologies such as insulation systems, exterior sheathing, and advanced roofing techniques. As early as the 14th–15th centuries, European craftsmen began adding small windows to steep sloped roofs to make attic spaces more functional, since those areas were typically dark and filled with smoke. The earliest dormer windows looked very modest, but by the 1600s French builders had transformed attic structures into true architectural highlights — almost works of art.

To this day, Parisian mansards remain an iconic reference point, shaping not only the character of individual buildings and sloped roofs but the identity of the entire city. This elegance and visual impact of classic Parisian dormer windows continue to inspire American architects and designers today.

In colonial settlements across Savannah, Charleston and St. Augustine, the iconic trio of roof dormer windows on a symmetrical façade became a visible marker of craftsmanship and prosperity. The wooden surrounds were heavy, carved, vulnerable to moisture, and required constant repainting — but their aesthetic value was undeniable.

The Victorian period pushed the style even further: elaborate gables, curved roofs, deep cornices, mixed materials. Some of the earliest predecessors of today’s large dormer windows appeared then — oversized, almost room-like forms.

The 20th century simplified the picture. With the rise of tract housing, attic dormer windows and small gabled dormer windows became standardized. But something changed in the last 25 years. Architectural shifted toward clean geometry and refined minimalism. Instead of ornamental pediments, we began seeing rectangular, streamlined modern dormer windows designed to visually stretch the roofline.

The turning point for using foam came when the construction industry began facing limitations with natural materials. Architects needed an architectural form — an element that would be geometrically precise, lightweight, and versatile in terms of textures, finishes, and color variations. Foam became the breakthrough material that met all of these requirements. It allowed us to create anything from classic window surrounds to ultra-modern framing solutions while reducing roof loads and simplifying installation. This gave architects and designers the freedom to form the exact visual identity they envisioned, without running into practical complications.

One of our projects in the historic district of Jacksonville illustrates this perfectly. The house, built in the early 1900s, still had its original wooden dormers, but time had taken its toll — the structures were deteriorating under their own weight. Our task was to recreate surrounds identical in texture, color, and proportions, yet lightweight, durable, and free from the maintenance demands of natural wood.

When our architectural elements were installed and we compared the before-and-after photos, we felt proud of the result. From the street, no one could tell whether the new gabled dormer window surrounds were made from wood or another material. They looked absolutely authentic — simply perfect.

Materials, technology and why foam became the new standard

Architectural foam used for dormer window surrounds is a structural, high-density material with engineered dimensional stability. Its role isn’t to pretend to be “cheap”; its role is to behave predictably.

Foam offers:

- 8–12× lower weight than cast minerals or stone;

- highly accurate fabrication with tight tolerances;

- the capability to form deep reveals, curved profiles and complex cornices;

- factory-applied coatings that imitate stone, stucco or wood with remarkable realism.

We’ve seen countless clients look at the window surrounds, tap on them, and still be unable to determine what they’re made of. And we’ve always loved that moment of surprise — it shows that our work has been executed flawlessly. This is exactly the essence of foam architectural elements: the moment when the aesthetics of traditional materials seamlessly transform into modern technology.

Engineering comparison: foam vs heavy alternatives

| Engineering focus | Architectural foam surround (high-density core) | Cast mineral / cementitious shells | Natural stone and other “heavyweights” |

|---|---|---|---|

| Load on roof framing | ≈ 1.4–2.1 lb/sq.ft, safe for old rafters and light trusses | 12–18 lb/sq.ft, often requires structural check | 20–35 lb/sq.ft, almost always requires reinforcement |

| Dimensional stability | Controlled thermal expansion, no microcracking | Medium stability, joints require monitoring | High density but significant thermal movement |

| Freedom of profile | Deep cornices, curves, complex types of dormer windows | Limited profiles, minimal curves | Very limited shaping options |

| Site work | Clean installation, no wet trades | Heavy, slow, messy installation | Needs stone masons and lifting equipment |

| Logistics | Lightweight shipping, fewer risks in transit | Moderate logistical costs | Very high costs and fragility |

| Finish | Factory-applied, stone/wood/metal texture | Must be finished on site | Requires sealing and maintenance |

| Longevity | Minimal maintenance, 20-year warranty | Coating degrades unevenly | High maintenance burdens |

Types of dormer windows and how they actually perform in real projects

Modern dormer windows

These are all about precision: crisp edges, rectangular fronts, minimal overhangs. Foam is ideal here because it allows thin profiles, exact geometry and clean integration with metal roofing.

We recently completed a boutique hotel in Tampa where the architect wanted an extremely minimalist silhouette. The five modern dormer windows we produced had nearly flush planes and a smooth “concrete” texture. Installation took one day — no cranes, no exterior painting, no special equipment.

Side dormer windows

Natural lighting and visibility. For example, in long corridors, on upper floors, in places where the roof pitch changes, or simply on a corner section of a building, side dormer windows break up the long lines of the structure in purely decorative, visual applications and add volume. And the use of foam makes it possible to vary the depth and slope without adding load. This is where they are most effectively used to solve.

Attic dormer windows

In renovation projects, these solutions become truly transformative and incredibly important. Turning a dark, unused attic into a livable space always begins with introducing natural light. The comfort inside then depends on the depth and shape of the surround. Foam makes it possible to create gabled dormer window surrounds with interior wall thicknesses perfectly suited for built-in furniture, window seats, or shelving.

One of our projects was in St. Augustine, where we created surrounds for three dormer windows. As a result, cozy interior niches formed inside the space, and the homeowners turned them into seating areas. Those interior dormer niches became the most cherished spot in the entire house.

Large shed dormer windows

These demand precision. Height, reveal, slope, load — everything must be perfect. Foam handles this beautifully because its weight remains low even at large sizes.

On a project near Atlanta, a long row of gabled dormer loft windows stretched above a gathering hall. Traditional stone would have required reinforcing the whole roof. Foam allowed a seamless 12-foot assembly that installed quickly and is still performing flawlessly years later.

Small hipped dormer windows

These are rhythm-setters. On long façades, small hipped dormer windows act like musical beats: adjust spacing and the entire building reads differently. Because foam can be fabricated with nearly identical precision across dozens of units, the facade rhythm stays clean and consistent.

How the manufacturing process actually works

The entire process looks like precise engineering, not just a small, lightweight decorative treatment. Everything begins with architectural data. You provide us with plans, drawings, elevations, BIM files, roof details, as well as diagrams showing the layout of the rafters. Our engineers determine the load paths, how to correctly design the overhang, how to ensure drainage, what the distances to the existing roofing should be, and what the relationships will be between the shed dormer window, its front plane, and the cornices. Only after this does the 3D model begin to be created.

The geometry is not invented or improvised — every part is calibrated, including angles, slopes, and everything else. After the model is approved, CNC programming begins. The foam material is cut with an extremely high level of precision — usually 1/16 inch, and for sensitive joints 1/32 inch. After machining, the foam core is reinforced with a protective shell that is specifically designed to increase impact resistance.

The coating thickness is calculated so that the element remains rigid for large spans, especially if these are large hipped gabled dormer windows. Only after this is the final finishing performed. We apply texture — it can be stone, wood, plaster, and so on. The color is selected according to the samples you provide to us or according to other specifications of your project.

The goal is ultimately to produce an architectural element and form that is fully finished from the moment it arrives and that at the job site it only needs to be installed after being taken out of the crate, without any refinishing or additional work. No priming, no treatments, no cutting — none of this will be required on site. All decorative elements are bonded by us at the factory; this reduces the number of installation errors and speeds up the installation process significantly.

Each element undergoes geometric inspection and coating-quality inspection at the production facility and is delivered with a full set of technical documentation, from drawings to installation instructions. We also provide consultation if any unforeseen questions arise.

Why foam hipped dormer surrounds are a strategic choice

Lightweight construction that protects the roof

The light weight prevents overloading rafters or trusses, making foam the safest option for renovations, historical structures and complex roof geometries. Even large shed dormer windows remain structurally manageable.

Factory-applied coating and protective finish

Every surround arrives at your project site fully finished and ready for installation. The coating of our architectural elements follows a specialized technology — a multilayer system similar to a finely built “layered shell.” Starting with the primer, each layer is applied step by step, and the final stage is a protective topcoat designed to ensure that every architectural element serves for decades without losing its quality. This is why all finishing is done at our production facility.

No additional coating, touch-ups, tinting or adjustments are required on site.

Precision geometry down to the millimetre

Because the architectural elements — especially window surrounds — fully match the project drawings, installers don’t need to spend time modifying, trimming or adjusting them during installation. This reduces labor costs and makes the installation process easier, smoother and free from the need for specialized skills.

Logistics that don’t inflate project budgets

Foam is light. Transporting even large assemblies is cost-efficient, safe and fast. Pre-assembled units reduce the number of crates and shipments.

Freedom of form and consistent stylistic language

You can mix classical pediments, modern rectangular hipped dormer windows, and subtle side dormer windows— all executed in one material with consistent finish. The building reads as a cohesive architectural story.

Minimal maintenance with 20-year warranty

Foam doesn’t absorb moisture, doesn’t rot, doesn’t delaminate, doesn’t require repeated sealing. With proper installation, these surrounds have a decades-long lifespan supported by a 20-year warranty.

All together, foam shed dormer surrounds deliver a rare architectural combination: they look sophisticated and richly detailed, yet behave like optimized, predictable engineered components.

If you’re designing a façade, planning a renovation or refining the roofline of a new project — simply send us your drawings. We will model the surround precisely, prepare a 3D visualization of hipped dormer windows interior, match textures and colors, and calculate shed dormer windows cost with clear logistics and a complete installation roadmap.

Leave a request in any format convenient for you, and we’ll prepare a tailored solution that preserves your architectural vision, protects your schedule and keeps your project structurally safe.

& specification catalog

Get the definitive guide to our custom decorative architectural foam shapes. This free catalog is packed with hundreds of design profiles, detailed technical specifications, and real-world project applications.

Have a project in mind?

Our dedicated specialists are ready to collaborate with you, turning your concept into a detailed plan with a transparent budget. Let’s bring your vision to life!