More than a railing. It's a statement of intent

We deliver the monumental aesthetic of traditional balustrades in a precisely engineered, impossibly lightweight system.

Engineered for Perfect Geometry

This is where safety meets artistry. Our decorative balustrades are engineered to provide the timeless, stately elegance you demand, but with a level of intelligence and efficiency that traditional materials can’t touch. They define spaces, frame views, and elevate a property’s entire aesthetic. From sweeping rooftop balustrades to elegant porch railings, our system delivers presence and permanence.

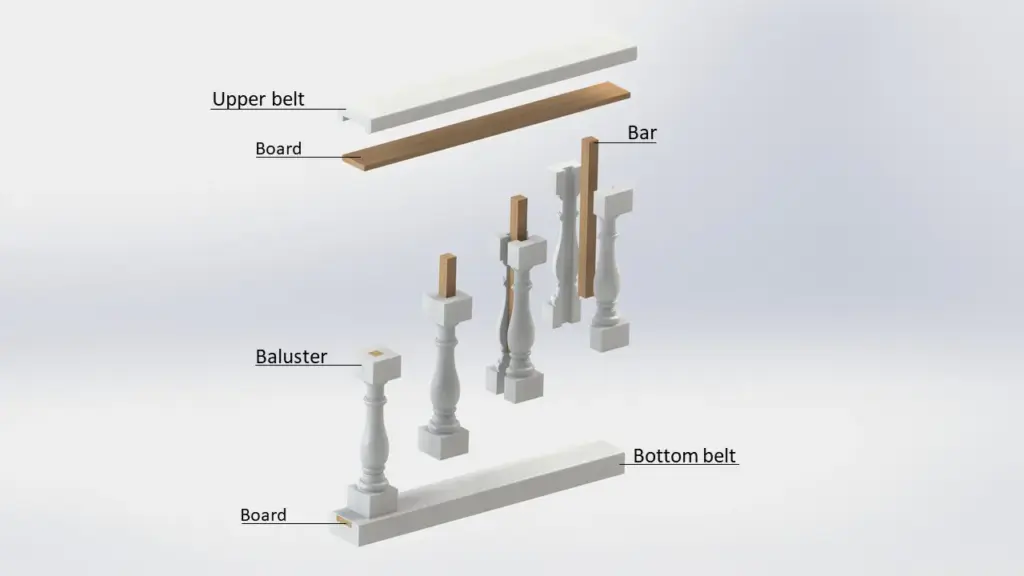

Each decorative balustrade is a complete, engineered system:

- Structural Composite Core: A high-density EPS core, precision-molded to create flawless polyurethane balusters, rails, and posts with perfect symmetry.

- Ballistic-Grade Polyurea Armor: Our signature polyurea hard coat transforms the lightweight core into a monolithic, impact-resistant element that’s 100% waterproof.

- Architectural Finish: A robust, integrated finish that replicates the texture of cast stone or painted wood, arriving on-site ready for immediate installation.

Get the look that inspires awe, with the performance that builds confidence.

The science of a maintenance-free masterpiece

We don’t build railings; we engineer solutions. At the core of every component of our balustrade system is a high-density Expanded Polystyrene (EPS) foam. This isn’t the foam you know. It’s a structural-grade material, shaped by computer-controlled technology to ensure every curve and line of your decorative railing is executed with absolute precision.

That core is then completely encapsulated in our proprietary polyurea hard coat. This isn’t paint. It’s a spray-applied armor that creates a seamless, waterproof shield with no joints or weak points. It makes the balustrade impervious to cracking, chipping, and weathering.

The result is a polyurethane balustrade that feels solid and substantial but is a fraction of the weight of concrete. It’s an advanced composite that delivers the aesthetic of the old world with the longevity and performance of 21st-century material science.

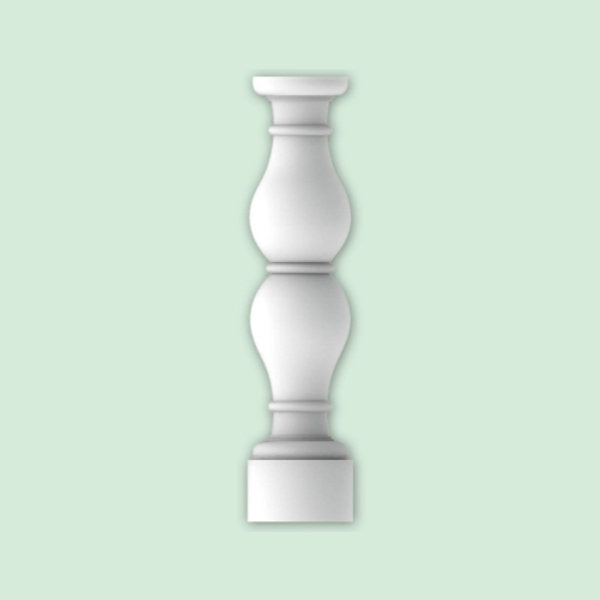

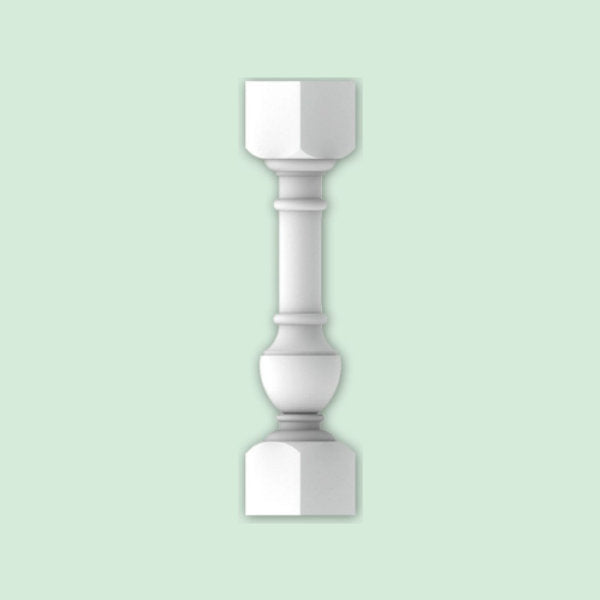

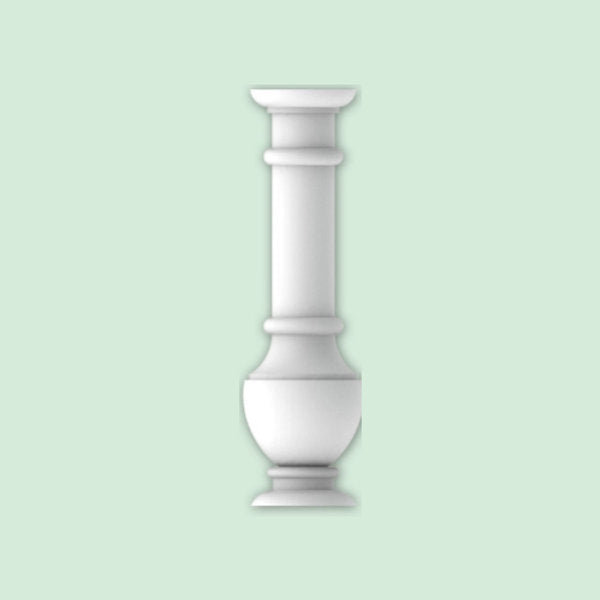

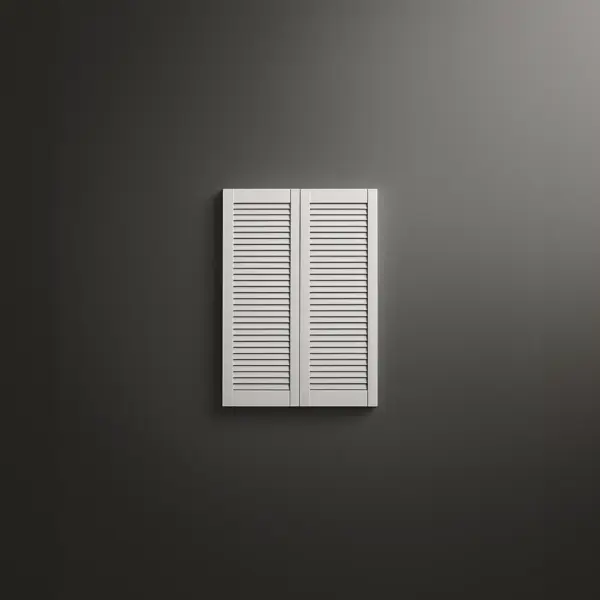

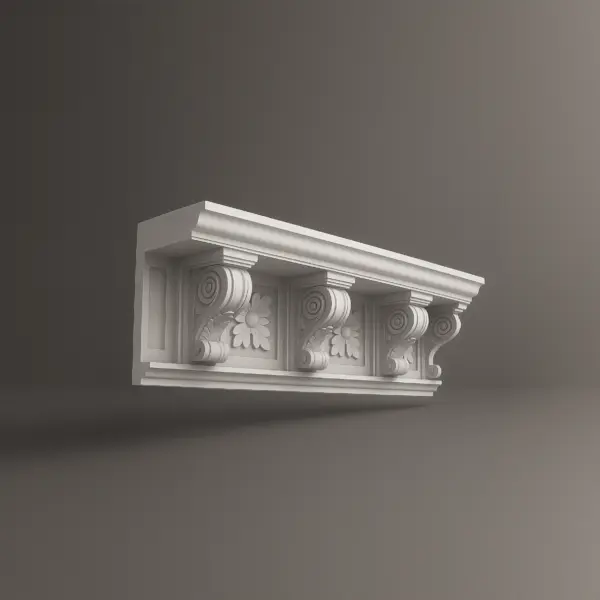

Assortment of balustrades and railings

The smart choice:

Engineered balustrades vs. traditional materials

The choice is clear. Our lightweight, durable, and fully custom decorative balustrades and railings are the superior solution. Made in the USA. Built for visionaries.

Demands cranes, reinforced structures, and large crews—a logistical and budget nightmare.

Requires skilled, expensive crews and slows down your entire facade schedule.

Vulnerable to rot, cracking, and water damage, demanding expensive and continuous maintenance.

Custom designs and curves are extremely time-consuming and costly, restricting your vision.

High initial expenses are compounded by years of costly maintenance and repairs.

Up to 90% lighter, eliminating cranes, structural reinforcement, and high shipping costs.

Arrives ready to assemble, letting a small crew accelerate your project timeline.

Impervious to rot, water, and cracking. A true "set it and forget it" solution.

Unlimited design freedom. CNC fabrication creates any custom curve, shape, or profile with perfect precision.

Lower total cost of ownership thanks to savings on labor, equipment, and zero lifetime maintenance.

Сustom balustrades and railings

How to order your architectural balustrade system

From your concept to your job site, our process is built for clarity, speed, and your complete confidence.

It all begins with a deep dive into your project. We work as your technical partner to transform creative intent into a solid, actionable plan.

- Analyze Your Inputs: We review your architectural plans, CAD files, sketches, and inspirational images to understand your design from every angle.

- Define the Scope: In a collaborative consultation, we discuss the project’s aesthetic goals, site conditions, and technical requirements to ensure a perfect fit.

- Establish a Technical Blueprint: We finalize all specifications, from dimensions to finish textures, creating a clear roadmap for fabrication that aligns perfectly with your vision.

We bridge the gap between concept and cost, providing you with the clarity and confidence to move forward.

- Receive a Detailed 3D Visualization: We create and send you a precise 3D model, allowing you to see exactly how your custom architectural elements will look before production begins.

- Get a Transparent, Itemized Proposal: You receive a clear, comprehensive quote with no hidden fees. We believe in total transparency, so you know exactly what you’re investing in.

- Maintain Complete Control for Final Approval: We don’t proceed until you are 100% satisfied. You have the final say on the design and budget before we move to the next stage.

This is where your approved design becomes a physical reality, crafted with an obsessive focus on quality in our 45,000 sq. ft. workshop.

- Execute with Robotic Accuracy: Our state-of-the-art CNC hot-wire machines carve your architectural elements with flawless precision, matching your approved 3D models to the exact specification.

- Armor for a Century of Performance: Our skilled artisans apply our signature Polyurea hard coat, creating a seamless, impact-resistant, and weatherproof shell designed for decades of durability.

- Verify Through Rigorous Quality Control: Every single piece undergoes a multi-point inspection to ensure it meets our exact standards for shape, finish, and structural integrity.

Our commitment extends all the way to your job site, ensuring a smooth and successful installation.

- Protect with Secure, Custom Crating: We build specialized shipping crates for every project, guaranteeing your elements arrive in pristine, ready-to-install condition.

- Streamline Your Installation: Your pieces are delivered pre-assembled and lightweight, designed to slash on-site labor time and eliminate the need for heavy machinery.

- Support Your Crew to the Finish Line: We provide detailed installation guides and offer live Zoom support to answer your team’s questions, guaranteeing a perfect final fit.

It all begins with a deep dive into your project. We work as your technical partner to translate creative intent into a solid, actionable plan.

- Analyze Your Inputs: We review your architectural plans, CAD files, sketches, and inspirational images to understand your design from every angle.

- Define the Scope: In a collaborative consultation, we discuss the project’s aesthetic goals, site conditions, and technical requirements to ensure a perfect fit.

- Establish a Technical Blueprint: We finalize all specifications, from dimensions to finish textures, creating a clear roadmap for fabrication that aligns perfectly with your vision.

We bridge the gap between concept and cost, providing you with the clarity and confidence to move forward.

- Receive a Detailed 3D Visualization: We create and send you a precise 3D model, allowing you to see exactly how your custom architectural elements will look before production begins.

- Get a Transparent, Itemized Proposal: You receive a clear, comprehensive quote with no hidden fees. We believe in total transparency, so you know exactly what you’re investing in.

- Maintain Complete Control for Final Approval: We don’t proceed until you are 100% satisfied. You have the final say on the design and budget before we move to the next stage.

This is where your approved design becomes a physical reality, crafted with an obsessive focus on quality in our 45,000 sq. ft. workshop.

- Execute with Robotic Accuracy: Our state-of-the-art CNC hot-wire machines carve your decorative architectural shapes with flawless precision, matching your approved 3D model to the millimeter.

- Armor for a Century of Performance: Our skilled artisans apply our signature Polyurea hard coat, creating a seamless, impact-resistant, and weatherproof shell designed for decades of durability.

- Verify Through Rigorous Quality Control: Every single piece undergoes a multi-point inspection to ensure it meets our exacting standards for form, finish, and structural integrity.

Our commitment extends all the way to your job site, ensuring a smooth and successful installation.

- Protect with Secure, Custom Crating: We build custom shipping crates for your elements, ensuring they arrive on-site in pristine, ready-to-install condition.

- Streamline Your Installation: Your pieces are delivered pre-assembled and lightweight, designed to slash on-site labor time and eliminate the need for heavy machinery.

- Support Your Crew to the Finish Line: We provide detailed installation guides and offer live Zoom support to answer your team’s questions, guaranteeing a perfect final fit.

Our project gallery

Engineered elegance for every application

Whether you’re chasing a vision or a deadline, our system is engineered for your success.

Finally, you can design those sweeping, dramatic rooftop balustrades and multi-level balcony railings without the structural engineer saying no. We give you the freedom to create iconic, view-framing elements that define a building’s character.

Turn your balconies and terraces from concrete slabs into high-value amenities. Our systems install exponentially faster than precast concrete, saving you critical time and labor costs, and helping you deliver a premium product to market faster.

Create unforgettable, high-end spaces for hotels, resorts, and luxury condos. Our architectural balustrades deliver the upscale look of stone with zero maintenance, ensuring your property looks pristine for guests year after year.

Perfectly replicate ornate, historic decorative balustrades with lightweight, modern materials. We can match intricate profiles with precision, preserving historical character without compromising the original structure.

Before and after:

from empty rooftop to premium amenity

Discover our workHow a balustrade defines your architectural value

A balustrade system does more than prevent falls; it creates a destination. It’s the architectural element that frames a view, defines an outdoor room, and communicates a powerful sense of quality and security. An elegant, well-proportioned balustrade is a non-verbal promise of a high-quality build.

- Frame the Experience, Elevate the ViewA beautiful decorative balustrade acts like the frame on a masterpiece painting. It draws the eye, adds depth, and makes the view from a balcony or terrace feel more intentional and exclusive.

- Create High-Value Amenity SpacesIn today's market, outdoor space is a luxury. A stunning balustrade system transforms a simple patio or rooftop into a desirable amenity—a place to gather, relax, and entertain—directly increasing a property's appeal and revenue potential.

- Communicate Enduring QualityUnlike metal railings that feel temporary or wood that rots, our engineered systems have the visual mass and permanence of stone. This signals a long-term investment in quality, building trust with buyers, tenants, and guests from the first glance.

Client testimonials

From your first idea to the final installation — our process is clear, fast, and designed to make every detail simple.

FAQ

Can you produce complex forms like spiral staircases or curved balconies?

Absolutely. EPS gives us complete freedom in shaping geometry. For a project in Tampa, we fabricated decorative balustrade panels that followed the exact curve of a circular atrium. Each piece was precision-cut and labeled, and installation took less than a day.

How do your products perform in humid, coastal environments?

Exceptionally well. EPS doesn’t absorb moisture, the polyurethane shell prevents microcracks, and the acrylic finish resists salt, UV, and heat. A set of decorative railing we installed in Sarasota has been standing strong for nine years — no repainting, no corrosion, no fading.

Is it possible to integrate our company logo or a custom pattern into the railing?

Yes, and it’s one of our most popular features. We can carve the logo directly into decorative railing panels or add it as a raised detail. At a Marriott property in Jacksonville, a custom motif became a signature design element and a guest photo hotspot.

What’s the typical production timeline?

It depends on project size and complexity, but most orders are completed within 3 to 4 weeks. For instance, we produced over 400 linear feet of balustrade systems for a residential project in Atlanta — including priming and finish — in just over four weeks.

What happens if a section gets damaged?

It’s easy to repair. EPS can be patched locally, and coatings can be reapplied without removing the entire section. In Orlando, after a piece was damaged during rooftop equipment delivery, we replaced just one element — and the repair was invisible.

Can we handle installation ourselves?

Yes. We don’t provide installation services, but every element is clearly labeled and designed for straightforward assembly. Most contractors find that our systems install 2–3 times faster than traditional materials.

Are these suitable for historical restoration?

They’re ideal. We can replicate profiles, textures, and even aged finishes down to the smallest detail. During a restoration project in Savannah, we recreated 19th-century balustrade systems so precisely that heritage inspectors couldn’t tell the originals from the replacements.

How do they handle temperature extremes?

They’re virtually unaffected. EPS doesn’t expand or contract like metal or wood, so you won’t see cracking or warping — even after years of freeze-thaw cycles.

Can they be repainted in the future?

Absolutely. All elements arrive prefabricated and ready to install, and you can repaint them on-site if you want to refresh the building’s look.

How quickly can we get samples?

Typically within a week of design approval. We’ll ship a texture sample and color recommendations so your team can evaluate them before finalizing the order.

& specification catalog

Get the definitive guide to our custom decorative architectural foam shapes. This free catalog is packed with hundreds of design profiles, detailed technical specifications, and real-world project applications.

Have a project in mind?

Our dedicated specialists are ready to collaborate with you, turning your concept into a detailed plan with a transparent budget. Let’s bring your vision to life!

More architectural shapes

We provide architects, builders, and homeowners with turnkey decorative elements that transform any project — fast, easy, and cost-effective.

Balustrades and railings

Every building tells a story. Not just through its walls or windows, but through its details — the subtle elements that shape perception and define character. And among those details, decorative railing, architectural balustrades and balustrade systems play a surprisingly powerful role. They guide the eye, create rhythm, and form the architectural punctuation that turns a structure into a statement.

With several decades of hands-on experience and thousands of completed projects behind us, we’ve learned that success in this field is about far more than manufacturing. It’s about understanding the dialogue between technology and design — how structural integrity, aesthetic nuance, and practical constraints can work together to create something truly distinctive. Every decorative railing and architectural balustrade we deliver is the result of that philosophy: not a copy-paste solution, but a carefully engineered, thoughtfully designed piece that elevates each project far beyond the ordinary.

Today, these are not just safety components within a building. They’re an integral part of its design, shaping the identity and visual perception of the entire project. It’s precisely these kinds of details that give architecture its unique appearance and character — a powerful factor that enhances its commercial appeal and increases its overall value, improving overall curb appeal for both residential and commercial developments.

The hidden power of railings: safety, story, and everything in between

In modern architecture, decorative railing is far more than a guardrail. It’s a multifunctional design solution that:

- Defines the visual logic of a facade and reinforces architectural lines.

- Creates safer, more intuitive environments — guiding how people move through a space while keeping elevated areas, terraces, and balconies secure without sacrificing design intent. Whether it’s directing foot traffic in a busy commercial atrium or providing peace of mind on a rooftop lounge, the right railing and balustrades make safety feel seamless and almost invisible.

- Adds emotional resonance and perceived value — transforming a purely functional structure into a place people want to be. A thoughtfully designed decorative balustrade does more than frame a view; it sets the mood, communicates sophistication, and leaves a lasting impression that elevates the entire property experience.

- Directly increases the market appeal — and price — of a property.

- Reduces lifetime maintenance costs and operational risks.

When we design a decorative balustrade or develop a set of decorative railing panels, we think beyond form. We engineer for logistics, installation speed, budget predictability, and long-term performance — so when the product arrives on site, it fits perfectly, works flawlessly, and looks exceptional.

A story written over centuries — and why it still matters

Balustrades have been shaping architecture for over five centuries, and their evolution is a masterclass in how aesthetics and engineering respond to cultural shifts.

In the Renaissance, heavy stone balustrade systems and stair railings were a sign of power and permanence. In the 18th century, iron brought elegance and lightness — ornate patterns that let buildings breathe. Modernism stripped everything back to pure function and geometry. And today, we have the freedom to combine all those influences, often in ways that weren’t even possible before.

This is where it gets exciting for today’s designers and developers: every era’s language is now available as part of your toolkit. In Sarasota, one of our clients took inspiration from Tuscan villa terraces and asked us to reimagine them for a rooftop restaurant. We crafted decorative balustrades with soft curves and a matte limestone-like texture. Guests now photograph the terrace daily — and every post becomes organic marketing.

Another example: a university library in Atlanta wanted to weave mid-century modern motifs into its new design. We produced decorative railing elements with crisp geometric lines and concealed fasteners — an homage to 1960s aesthetics but built with 21st-century efficiency.

Materials and technology: precision at the core

We don’t use metal. We don’t pour concrete. We don’t work with white pine or any other traditional material. Every architectural balustrade, decorative railing panel, and polyurethane baluster we produce is engineered from advanced high-density expanded polystyrene (EPS), coated with a hard aromatic polyurethane layer and finished with an aggregated acrylic texture.

The heart of each system is a molded EPS core. It’s lightweight yet incredibly strong, moisture-resistant, doesn’t warp or rot, and is immune to insect damage — making it ideal for both indoor and outdoor space use.

Over that core, we apply a fast-curing, impact-resistant polyurethane shell. This layer dramatically enhances structural strength, protecting against impact, abrasion, and UV exposure.

The final surface is a 100% aggregated acrylic finish, formulated to withstand harsh weather while offering endless aesthetic possibilities. From the look of carved stone to aged metal or natural wood, we can replicate virtually any texture or finish you imagine. All products arrive prefabricated, so your design intent stays intact down to the last detail.

What does this mean in practice? Our polyurethane balustrades and exterior decorative railing systems:

- Resist moisture, pests, peeling, cracking, and fading.

- Require almost no maintenance and never corrode.

- Deliver consistent geometry and structural stability for decades.

- Arrive installation-ready, reducing labor hours and site work.

On a project in Jacksonville, replacing planned concrete guardrails with polyurethane balustrade systems cut the weight load by 80%. This eliminated the need for slab reinforcement — saving the developer over 18% of the total project budget.

Why these systems outperform anything else

| Benefit | Details |

|---|---|

| Feather-light, heavy-duty | Four to six times lighter than traditional materials, simplifying transport, handling, and installation. |

| Design freedom | Complex profiles, intricate patterns, custom logos, and branded motifs — all achievable with precision. |

| Weatherproof durability | Resistant to moisture, UV rays, insects, and extreme temperature shifts. |

| Cost efficiency | Lower logistics costs, faster installation, and virtually zero maintenance. |

| Prefabricated | Arrive ready for a quick and easy installation. |

| Seamless integration | Ready to adapt to any architectural style — classic, modern, or anything in between. |

Where these systems make the biggest impact

Facades and terraces

In Miami, we helped a developer completely transform a high-rise residential project. They needed the facade to feel lighter and more upscale. Our balustrade did just that, becoming a focal point of the building.

Rooftops and observation decks

For a hotel in St. Petersburg, we created custom rooftop balustrade systems engineered to handle coastal wind loads while integrating with the roof’s drainage system. Because of the lightweight design, no additional slab reinforcement was needed — and the rooftop restaurant stayed open throughout construction.

Interiors and public spaces

At a university campus in Georgia, we produced foam baluster components with gentle curvature and a soft stone-like finish. The lightweight, precision-milled components allowed for delicate, floating stair balustrades that became a centerpiece of the interior.

Why working with us just makes sense

- U.S.-based manufacturing and full quality control.

- Complete design flexibility — from profile and texture to finish and color.

- Detailed engineering documentation, load calculations, and installation specs.

- Sustainable, lightweight, and impact-resistant materials built to last.

- Predictable lead times and reliable delivery schedules.

- Guaranteed precision and dimensional accuracy.

We’re not just a supplier — we’re a strategic partner who helps turn ideas into architecture. That’s why companies like Disney, Hilton, and Universal Studios trust us with their most visible spaces.

& specification catalog

Get the definitive guide to our custom decorative architectural foam shapes. This free catalog is packed with hundreds of design profiles, detailed technical specifications, and real-world project applications.

Have a project in mind?

Our dedicated specialists are ready to collaborate with you, turning your concept into a detailed plan with a transparent budget. Let’s bring your vision to life!