About our exterior cornice systems

Achieve the gravitas of stone and stucco with a system built for today’s timelines.

The look of precast. The speed of prefab

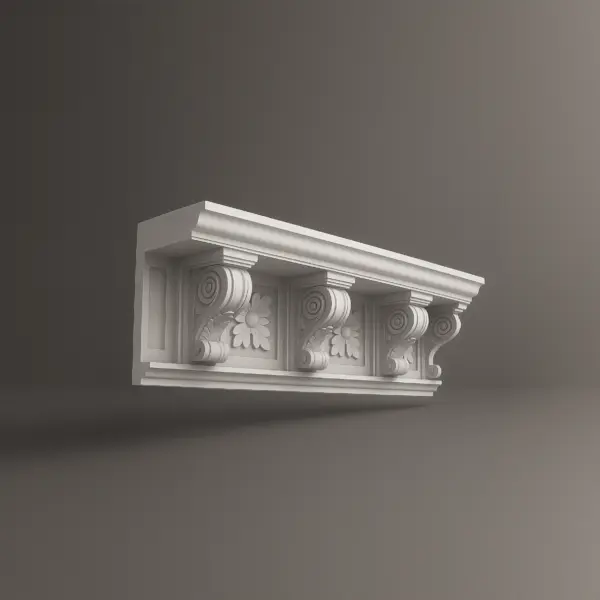

A cornice is more than trim; it’s the powerful line that defines a building’s character. Our architectural cornices are engineered to provide that defining character without the engineering headaches. We replicate the monolithic look of precast concrete or classic stucco, but in a lightweight, prefabricated system that’s built for modern construction timelines.

Each exterior cornice system is a fusion of three key elements:

- Structural EPS Core: A high-density foam core, precision-cut to any profile you can design. This is where your vision takes shape.

- Polyurea Armor: Our signature hard coat that encapsulates the foam, creating an impact-resistant, waterproof shell.

- Architectural Finish: A ready-to-paint surface that achieves the authentic texture of masonry, ready to integrate seamlessly into your facade.

Get a flawless architectural finish that installs in a fraction of the time.

The science behind a flawless exterior cornice

Our foam cornice systems are born from advanced material science. It starts with a structural, high-density Expanded Polystyrene (EPS) foam block. Using state-of-the-art CNC technology, we carve this block with absolute precision, ensuring every curve, angle, and detail of your design is perfectly replicated.

The real transformation happens next. We encapsulate the shaped foam in our proprietary polyurea hard coat. This isn’t just a coating; it’s architectural armor. The spray-applied elastomer creates a seamless, waterproof, and incredibly durable shell, turning a lightweight core into a monolithic element that resists impact, moisture, and extreme weather.

The final layer is an integrated, architectural stucco cornice moulding finish, providing the authentic texture and appearance of solid masonry. This is how we deliver an exterior foam cornice that is not only beautiful but engineered to last for decades.

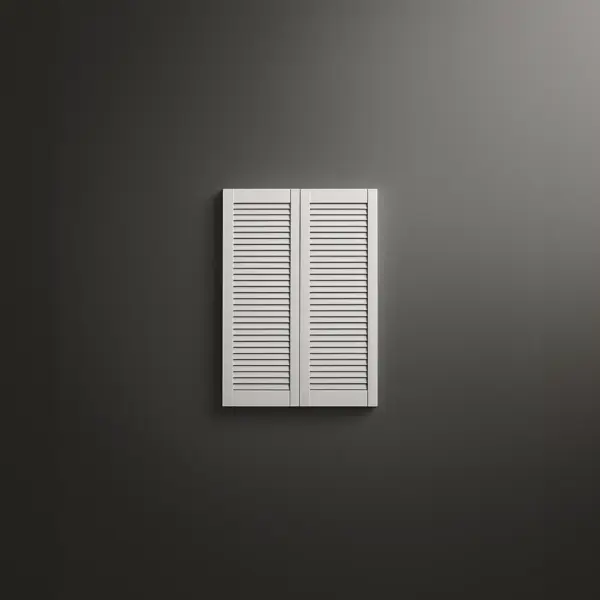

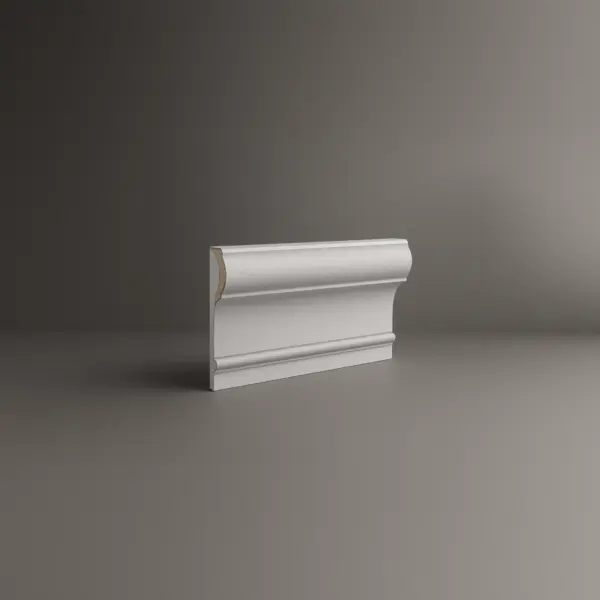

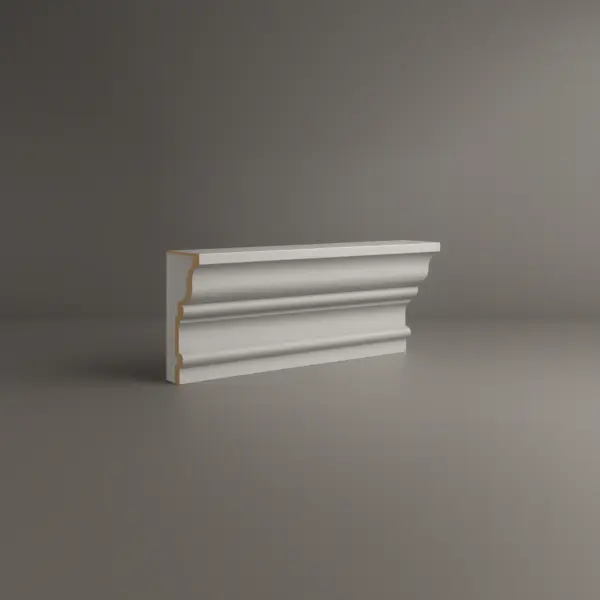

Assortment of commercial and residential cornices

Exterior foam cornice vs. traditional materials:

The Decorative Architectural Shapes advantage

It’s time for a smarter solution—an exterior cornice built for the demands of today’s projects. Made in the USA.

Requires heavy machinery, structural reinforcement, and large crews, inflating budgets and complexity.

Installation takes weeks due to slow masonry work, mortar curing, and constant weather delays.

Prone to cracking (concrete) or rot (wood). Requires constant, costly maintenance and repairs.

Designs are restricted by mold limitations and weight. Custom work is extremely difficult and expensive.

High upfront costs for materials, labor, and equipment, plus expensive ongoing maintenance.

Up to 90% lighter. No cranes or structural reinforcement needed, slashing logistics and labor costs.

Prefabricated system installs in days, not weeks, accelerating project timelines and saving on labor.

Impervious to water, rot, and pests thanks to a polyurea shell. Zero maintenance with an 80-100 year lifespan.

Unlimited design freedom. We can fabricate any complex profile, curve, or historic detail from your drawings.

Lower total project cost with major savings on labor, equipment, shipping, and future maintenance.

Сustom commercial and residential cornices

How to order architectural cornices

From your initial CAD file to job site delivery—our process is engineered for your efficiency and peace of mind.

It all begins with a deep dive into your project. We work as your technical partner to transform creative intent into a solid, actionable plan.

- Analyze Your Inputs: We review your architectural plans, CAD files, sketches, and inspirational images to understand your design from every angle.

- Define the Scope: In a collaborative consultation, we discuss the project’s aesthetic goals, site conditions, and technical requirements to ensure a perfect fit.

- Establish a Technical Blueprint: We finalize all specifications, from dimensions to finish textures, creating a clear roadmap for fabrication that aligns perfectly with your vision.

We bridge the gap between concept and cost, providing you with the clarity and confidence to move forward.

- Receive a Detailed 3D Visualization: We create and send you a precise 3D model, allowing you to see exactly how your custom architectural elements will look before production begins.

- Get a Transparent, Itemized Proposal: You receive a clear, comprehensive quote with no hidden fees. We believe in total transparency, so you know exactly what you’re investing in.

- Maintain Complete Control for Final Approval: We don’t proceed until you are 100% satisfied. You have the final say on the design and budget before we move to the next stage.

This is where your approved design becomes a physical reality, crafted with an obsessive focus on quality in our 45,000 sq. ft. workshop.

- Execute with Robotic Accuracy: Our state-of-the-art CNC hot-wire machines carve your architectural elements with flawless precision, matching your approved 3D models to the exact specification.

- Armor for a Century of Performance: Our skilled artisans apply our signature Polyurea hard coat, creating a seamless, impact-resistant, and weatherproof shell designed for decades of durability.

- Verify Through Rigorous Quality Control: Every single piece undergoes a multi-point inspection to ensure it meets our exact standards for shape, finish, and structural integrity.

Our commitment extends all the way to your job site, ensuring a smooth and successful installation.

- Protect with Secure, Custom Crating: We build specialized shipping crates for every project, guaranteeing your elements arrive in pristine, ready-to-install condition.

- Streamline Your Installation: Your pieces are delivered pre-assembled and lightweight, designed to slash on-site labor time and eliminate the need for heavy machinery.

- Support Your Crew to the Finish Line: We provide detailed installation guides and offer live Zoom support to answer your team’s questions, guaranteeing a perfect final fit.

It all begins with a deep dive into your project. We work as your technical partner to translate creative intent into a solid, actionable plan.

- Analyze Your Inputs: We review your architectural plans, CAD files, sketches, and inspirational images to understand your design from every angle.

- Define the Scope: In a collaborative consultation, we discuss the project’s aesthetic goals, site conditions, and technical requirements to ensure a perfect fit.

- Establish a Technical Blueprint: We finalize all specifications, from dimensions to finish textures, creating a clear roadmap for fabrication that aligns perfectly with your vision.

We bridge the gap between concept and cost, providing you with the clarity and confidence to move forward.

- Receive a Detailed 3D Visualization: We create and send you a precise 3D model, allowing you to see exactly how your custom architectural elements will look before production begins.

- Get a Transparent, Itemized Proposal: You receive a clear, comprehensive quote with no hidden fees. We believe in total transparency, so you know exactly what you’re investing in.

- Maintain Complete Control for Final Approval: We don’t proceed until you are 100% satisfied. You have the final say on the design and budget before we move to the next stage.

This is where your approved design becomes a physical reality, crafted with an obsessive focus on quality in our 45,000 sq. ft. workshop.

- Execute with Robotic Accuracy: Our state-of-the-art CNC hot-wire machines carve your decorative architectural shapes with flawless precision, matching your approved 3D model to the millimeter.

- Armor for a Century of Performance: Our skilled artisans apply our signature Polyurea hard coat, creating a seamless, impact-resistant, and weatherproof shell designed for decades of durability.

- Verify Through Rigorous Quality Control: Every single piece undergoes a multi-point inspection to ensure it meets our exacting standards for form, finish, and structural integrity.

Our commitment extends all the way to your job site, ensuring a smooth and successful installation.

- Protect with Secure, Custom Crating: We build custom shipping crates for your elements, ensuring they arrive on-site in pristine, ready-to-install condition.

- Streamline Your Installation: Your pieces are delivered pre-assembled and lightweight, designed to slash on-site labor time and eliminate the need for heavy machinery.

- Support Your Crew to the Finish Line: We provide detailed installation guides and offer live Zoom support to answer your team’s questions, guaranteeing a perfect final fit.

Our project gallery

Engineered solutions for every project

No matter your role, our systems are engineered to help you succeed.

Create premium curb appeal that accelerates sales and leases. We provide standardized, high-quality cornice profiles for entire communities or commercial parks, ensuring a unified, upscale aesthetic with an installation speed that keeps your project ahead of schedule.

Finally, realize your vision without compromise. We fabricate custom stucco cornice profiles to your exact CAD specifications, from massive, multi-layered overhangs to delicate exterior window cornice details. We provide the technical partnership you need to push creative boundaries.

Define your brand’s physical presence. A strong exterior cornice from Decorative Architectural Shapes adds a look of permanence and quality to hotels, corporate campuses, and retail centers. It’s a low-maintenance, high-impact investment in your property’s value.

Craft a statement of timeless elegance. Our systems allow you to add custom foam cornice boards for windows or a grand roofline cornice that provides the perfect finishing touch, creating a truly custom home without the massive cost of traditional masonry.

Before and after:

A strategic transformation

Discover our workHow our cornice elevates your building's value

A cornice is the crown of your building. It’s the architectural detail that communicates quality, permanence, and attention to detail before anyone steps inside.

- Architectural Character that Builds ValueA well-designed cornice exterior adds depth, shadow, and sophistication. It demonstrates an investment in quality craftsmanship, establishing credibility with clients, tenants, and investors alike.

- Engineered for Longevity, Not MaintenanceUnlike wood that rots or concrete that cracks, our foam cornice systems are inert. The polyurea shell is built to withstand harsh weather, UV rays, and time—staying pristine year after year with zero maintenance. This is the definition of a smart, long-term asset.

- Custom Profiles for a Signature LookYour building should have a unique identity. With unlimited design possibilities, our architectural cornices can be tailored to perfectly align with your brand's architectural style, whether it’s classically inspired or aggressively modern.

Client testimonials

From your first idea to the final installation — our process is clear, fast, and designed to make every detail simple.

FAQ

Is it possible to go beyond standard profiles — say, create something completely custom with unique shapes, unusual geometry, or even elements that have never been done before?

In Atlanta, a client wanted a custom facade for a corporate headquarters. We engineered extreior cornice with integrated lighting channels that mirrored the company’s logo — a distinctive architectural feature that attracted tenants even before construction was complete.

What if historical accuracy is critical?

We can recreate architectural details with millimeter precision. In St. Augustine, we manufactured exterior cornice for a 19th-century building restoration. The profiles matched the originals exactly but were lighter, more durable, and easier to install.

What if we need something unique and not realistic to do?

That’s our specialty. In Jacksonville, we worked with an architect on a design featuring dynamic geometric lines. We engineered a fully custom foam cornice system that supported the facade’s visual rhythm while concealing lighting and drainage systems inside. The result became a signature part of the brand’s architectural identity.

What if we have a big grade change?

No problem. Foam follows contours far more easily than concrete or masonry. Instead of awkward steps, we can create smooth transitions that maintain visual calm and proper drainage.

Will a white finish last in coastal weather?

It will if the system is specified correctly. With the right coating and finish, walls along the Gulf Coast have stayed chalk-free and color-true for years. Occasional rinsing is usually all the maintenance required.

Are foam panels strong enough for high winds?

Yes. When everything is engineered thoughtfully — from precise anchor spacing to slightly shortened modules in the most exposed spots — the fence doesn’t behave like a fragile structure, but like a seasoned sailor standing firm on deck in the middle of a storm. Even hurricane-level coastal winds don’t faze it: it doesn’t shift a millimeter, doesn’t crack, and never gives in to the elements. At one property near Daytona Beach, the fence looked as if it had been installed yesterday, even after an entire storm season — perfectly straight, steady, and untouched. It’s more than just strength; it’s a quiet confidence you can feel when you look at it, as if the architecture itself is saying, “I’m right where I belong — and I’m not going anywhere.”

Can we include a recessed logo without a billboard look?

Definitely. Because foam is so easy to shape, recessed details feel purposeful rather than forced. One Atlanta property incorporated its logo into a shadowed niche with subtle lighting — the effect is elegant by day and welcoming at night.

Is six feet high enough for privacy?

Often, yes. Especially when paired with strategic planting. And if local codes require more, we can add height without creating a fortress-like presence.

What do you need to provide a quote?

Length, height, a style cue, and a few photos. Include a color sample early and we can return strike-offs with the estimate — speeding approvals by up to a week.

We want a wood look without the upkeep.

We can achieve that easily. Slim aluminum fins paired with textured foam surfaces create the warmth and light play of wood without rot, refinishing, or fading. On one residential project, the “wood” still looked fresh three seasons later with nothing more than a garden hose rinse. The result was as visually appealing as natural wood and perfectly matched the desired look of the homeowner.

Can I get samples before placing an order?

We encourage it. We know that choosing the right foam cornice is not just about measurements on paper — it’s about texture, weight, finish, and how the element feels in your hands. That’s why we’re always happy to send real samples your way. It’s a simple step, but it makes a big difference: you get to see, touch, and truly understand what you’re choosing, which means every decision you make is backed by confidence, not guesswork.

& specification catalog

Get the definitive guide to our custom decorative architectural foam shapes. This free catalog is packed with hundreds of design profiles, detailed technical specifications, and real-world project applications.

Have a project in mind?

Our dedicated specialists are ready to collaborate with you, turning your concept into a detailed plan with a transparent budget. Let’s bring your vision to life!

More architectural shapes

We provide architects, builders, and homeowners with turnkey decorative elements that transform any project — fast, easy, and cost-effective.

Commercial and residential cornices

If you’re developing a commercial property or a residential complex, you’ve probably faced the same challenge: how to make the facade striking, recognizable, and memorable — without blowing up your budget or missing deadlines. That’s where architectural elements like exterior cornice become more than just decoration — they turn into a strategic tool. They help differentiate your brand, increase the property’s value, and minimize costly project risks.

At Decorative Architectural Shapes, we’ve been creating architectural solutions for over 25 years, and we know exactly how to turn this detail into a competitive advantage. Our foam cornice isn’t just a beautiful line on a facade. It’s precision, reliability, predictability, and creative freedom. They save time, reduce costs, simplify installation, and open the door to bold architectural ideas — from timeless classical to ultra-modern minimalist styles.

What cornices are and why they matter

An exterior cornice is not just “decoration.” It’s the upper profile that completes the composition of a building, provides a visual accent, and protects the walls from water damage. Well-designed exterior cornice can dramatically transform how a building is perceived — visually increasing height, adding depth and sophistication, and highlighting the architectural style. In commercial projects, it’s also a powerful tool for brand visibility — after all, the first impression starts at the curb.

Materials and technology: answering real concerns

I’m trying to plan my construction schedule down to the day, and honestly, I’m worried. Everyone tells me installing cornices is a headache — cranes, scaffolding, extra workers, delays — and I just can’t afford surprises like that. How complicated is it really, and what does the process look like step by step?

At Decorative Architectural Shapes, we hear this concern all the time — and we get it: your schedule, budget, and team resources matter. The truth is, installation with our exterior cornice molding is far simpler than most people expect. Because our elements are 10–12 times lighter than stone or concrete. The light weight is the first plus. They’re installed by hand — no cranes, no specialized crews. We also supply detailed mounting guides and labeled parts, so everything fits seamlessly on-site.

On a recent retail project in Fort Lauderdale, what was originally planned as a three-week installation was completed in just eight days — same team, no heavy equipment, and zero schedule disruptions. That’s exactly the kind of predictability we design for.

Not sure about durability?

Our high-density architectural foam is built to last decades. It doesn’t absorb moisture (water absorption <1.5%), doesn’t corrode, resists UV rays, and handles extreme temperatures with ease. Each stucco cornice is coated with a specialized protective layer that maintains its appearance and structural integrity for 30–40 years or more.

Think customization is slow and expensive?

It’s actually our greatest strength. We don’t just offer standard profiles — we create fully custom solutions for every project. In a residential redevelopment project in Sarasota, the client initially came to us only for foam surrounds for windows. During the design process, we developed a complete facade concept aligned with their brand vision, and the scope grew — they ended up ordering not just cornices, but also fireplace surrounds, decorative panels, and window trim. The unified design became a key marketing point when selling the property.

Why foam has changed the game

Foam cornice is truly a breakthrough in modern architecture. With a density of just 1–2 lbs per cubic foot, it can withstand significant wind loads and mechanical stress. Its thermal conductivity is 10 times lower than concrete, and its weight is 7 times lighter — significantly reducing the load on structural systems.

Because of this, foam cornice and crown moldings opens up design possibilities like never before. It can be shaped into virtually any form — from elaborate baroque ornamentation to minimalist straight lines. And the surface finish can mimic stone, wood, or metal so convincingly that even experts often can’t tell the difference. It allows architects and designers to create features that were once impossible or prohibitively expensive.

Where cornices deliver real value — where Decorative Architectural Shapes solutions truly make a difference

Modern exterior cornice solutions aren’t just “pretty trim” anymore — they’re the place where bold design dreams shake hands with real-world engineering. It’s where creativity steps out of the sketchbook and starts shaping how a building feels, functions, and tells its story before anyone even walks through the door.

From a marketing perspective, they’re one of the most powerful ways to shape how people feel about a building the moment they see it. From an engineering perspective, they’re smart, purpose-driven elements that strengthen and highlight a building’s architecture. Combined with their visual impact, they turn a simple detail into a strategic feature — one that shapes identity and leaves a lasting impression.

Hotels and resorts: first impressions that sell rooms

In hospitality, the facade is often the very first interaction guests have with the brand. Architectural elements like foam cornice help set expectations before a visitor even steps inside. A well-designed exterior signals quality, elevates brand perception, and often becomes the difference between “just another hotel” and a destination. Clean lines, well-defined profiles, and carefully planned accents make properties feel premium — and that directly impacts occupancy rates and guest satisfaction.

Churches and heritage sites: turning structures into sacred spaces

Religious architecture is deeply emotional — it’s about identity, community, and continuity. And here, stucco cornice molding can do more than replicate the past; it can bring meaning to a structure.

We once worked on a church in Jacksonville that originally looked more like an office building than a place of worship. Our team designed custom foam cornice elements with a finish that mimicked centuries-old stone — complete with weathered texture and subtle patina.

When the renovation was complete, the transformation was striking. What was once a plain building became a true sanctuary, with depth, character, and presence. The restoration team later shared something that stuck with us: “What surprised us most wasn’t the architecture — it was the priest’s reaction. He said he saw the congregation’s faces light up. They said it finally felt like a real home for their faith.”

A similar story unfolded in Savannah, where we restored a 19th-century church using lightweight stucco cornice replicas. They matched the original design but weighed eight times less, preserving the historic look while simplifying installation. Today, the church stands as one of the city’s most photographed landmarks.

Retail and commercial centers: design that drives foot traffic

In retail, visibility equals revenue. Architectural detailing helps buildings stand out in crowded commercial zones, catching the eye of potential customers and creating a sense of identity. Well-planned exterior cornice molding adds hierarchy to a facade, creates inviting entrances, and subtly guides visitors toward key points of interest — all of which directly support business performance.

Office buildings: a visual extension of brand values

For corporate projects, facade design is about more than aesthetics — it communicates reliability, authority, and professionalism. With carefully selected exterior cornice profiles, office buildings can project strength and trustworthiness before clients ever walk through the door, supporting the brand narrative from the outside in.

Residential developments: enhancing perceived value

In residential real estate, especially in commercial buildings, perception is everything. Architectural details like stucco cornice instantly elevate curb appeal and influence how potential buyers value a property. A thoughtfully designed facade can justify premium pricing, accelerate sales, and help a project stand out in a competitive market.

Installation: precision, speed, and reliability

We don’t handle installation ourselves, but we make sure it goes as smoothly as possible. Every exterior foam cornice is delivered with complete technical documentation: detailed drawings, installation guides, and material compatibility recommendations. All components are labeled for quick and accurate assembly, eliminating guesswork and delays.

We also provide consultation and support at every stage — from design to final installation. That means each element fits perfectly into place, with no costly rework. The process becomes a reliable, predictable part of the construction schedule — exactly what professional contractors need.

Why partnering with us is a strategic choice

We don’t just offer a stucco cornice. We offer a solution that’s designed specifically for your project, which is why it helps your building achieve complete architectural harmony. We don’t just hand you a product and step back — we roll up our sleeves and dive into the project with you. From those first rough sketches and “what if” ideas to detailed 3D visualizations, material samples, delivery planning, and on-site guidance, our team stays in the room at every stage. Think of us less as a supplier and more as an extension of your design and engineering team — one that’s just as invested in the final result as you are.

With us, you avoid schedule delays, hidden costs (for example, installation costs), and on-site errors. You get a trusted engineering partner who understands your goals and knows how to achieve them. That’s why leading developers, hotel chains, architectural firms, and construction companies across the U.S. trust Decorative Architectural Shapes with their most ambitious projects.

& specification catalog

Get the definitive guide to our custom decorative architectural foam shapes. This free catalog is packed with hundreds of design profiles, detailed technical specifications, and real-world project applications.

Have a project in mind?

Our dedicated specialists are ready to collaborate with you, turning your concept into a detailed plan with a transparent budget. Let’s bring your vision to life!