About our architectural molding systems

Go beyond standard trim with a precision-engineered molding system designed to define your building’s architectural character.

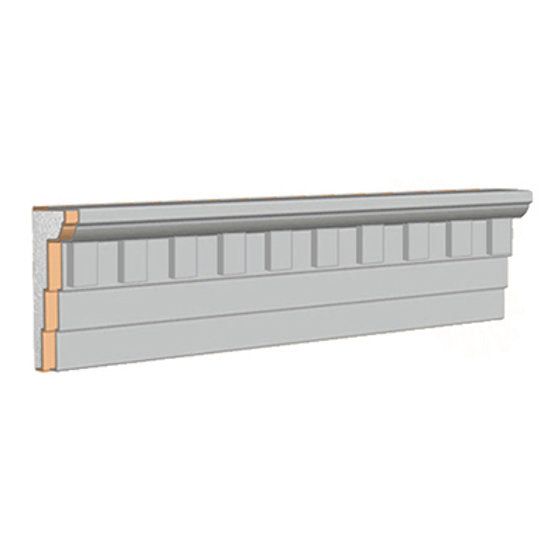

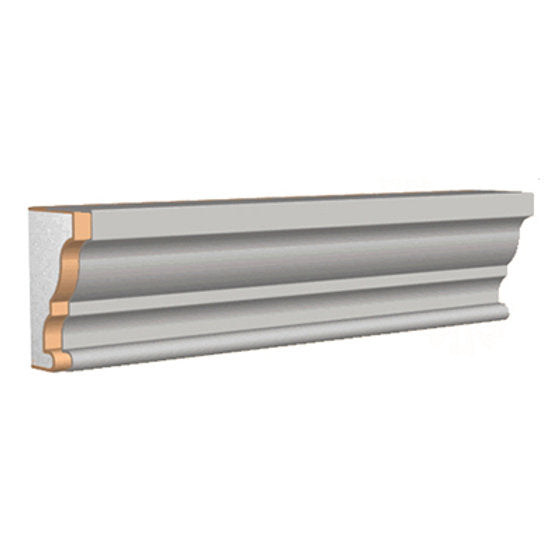

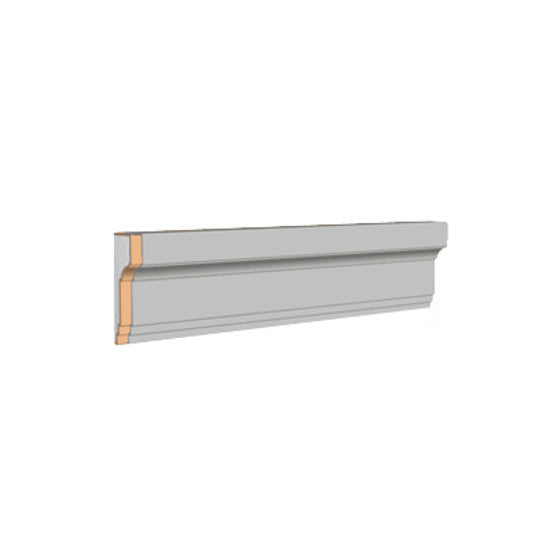

Architectural crown moldings, built without compromise.

Engineered for precision, designed for impact. Our crown moldings are more than just decorative trim; they are high-performance architectural elements crafted to define and elevate your building’s character. Forget the limitations of off-the-shelf products from Crown Molding Home Depot or Lowe’s. We create custom profiles to your exact specifications.

Each piece is a fusion of art and engineering, fabricated from a high-density, lightweight EPS foam core. This allows for the creation of large crown molding profiles and intricate decorative crown molding that would be structurally impossible or financially prohibitive with traditional materials. It’s the key to achieving a high-end aesthetic with smarter, more efficient construction methods.

Get a system that is engineered for perfection and delivered ready for rapid installation.

The science behind a flawless, feather-light facade

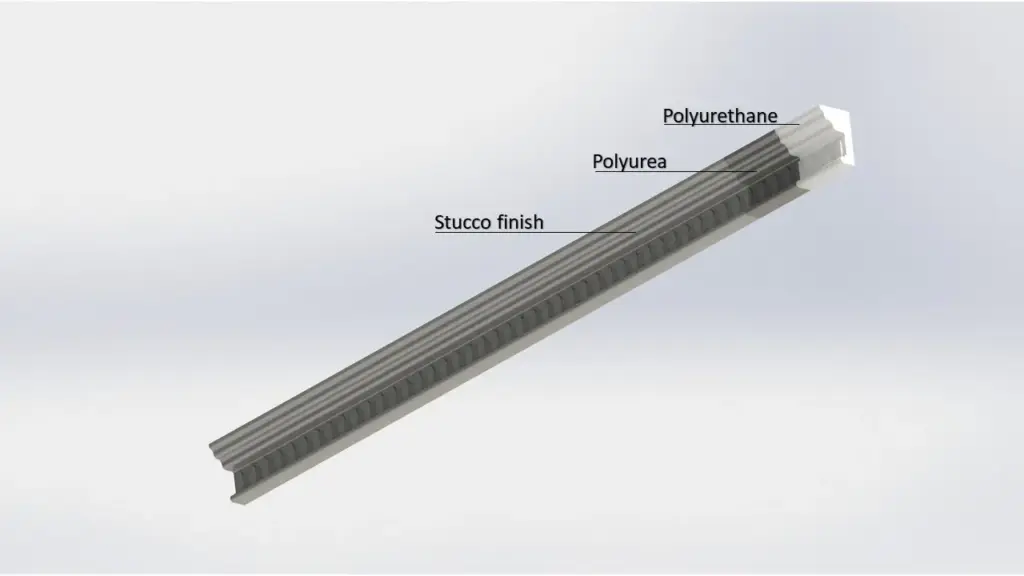

Our architectural cornices are built on an advanced material composite, engineered for a century of performance. The process begins with a structural, high-density Expanded Polystyrene (EPS) foam core, which we precision-cut using CNC technology. This ensures every miter, curve, and detail of your custom crown molding is geometrically perfect, guaranteeing flawless crown molding angles and seamless connections.

The core is then encapsulated in our signature polyurea hard coat. This isn’t just a coating; it’s armor. The spray-applied elastomer creates a monolithic, waterproof, and impact-resistant shell, transforming the lightweight foam into a structure with incredible resilience.

Finally, we apply an integrated, architectural-grade finish, like our stucco cornice moulding, that provides the authentic texture of masonry and superior resistance to weathering and UV degradation. This is how we build lightweight elements that outperform and outlast their heavyweight predecessors.

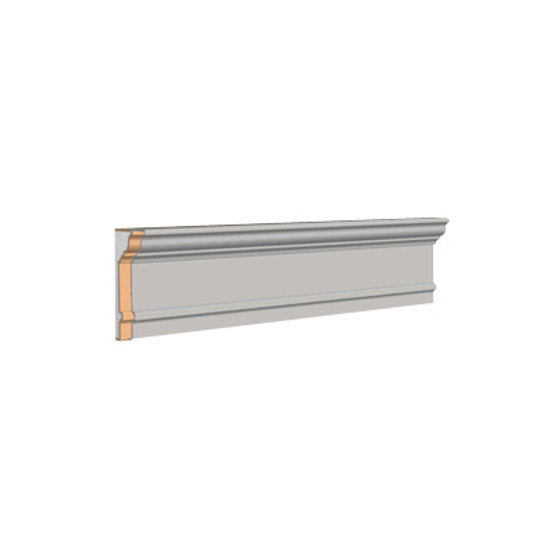

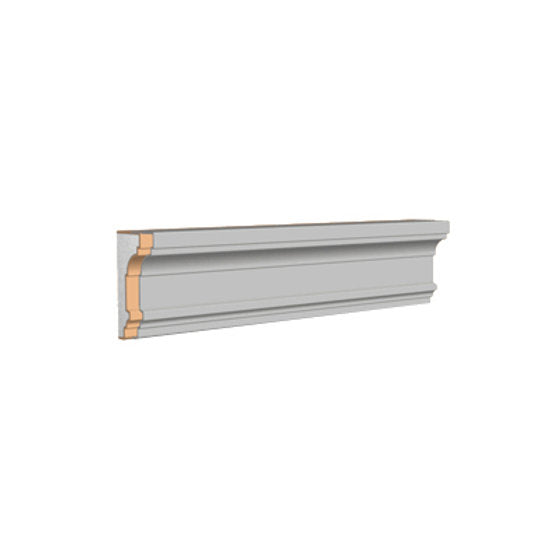

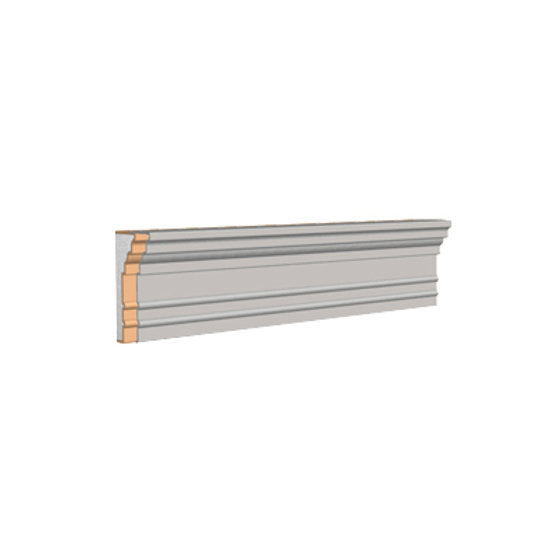

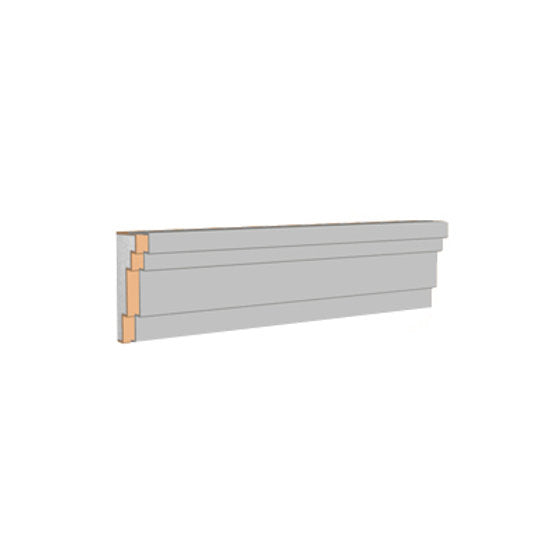

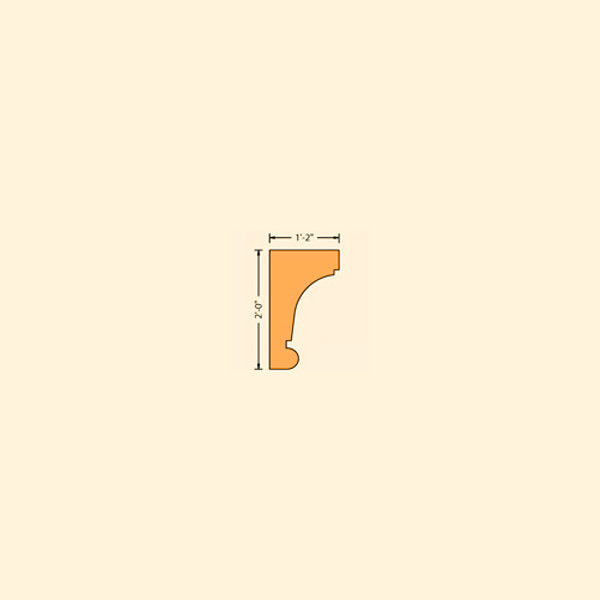

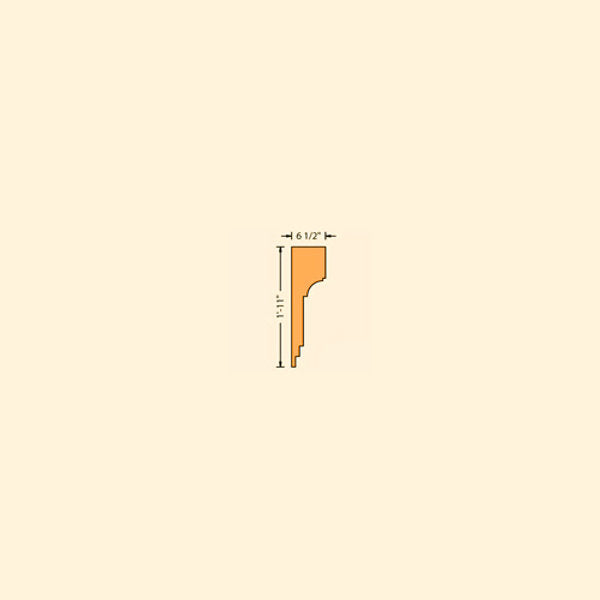

Assortment of crown moldings

Foam crown molding vs. traditional materials:

The Decorative Architectural Shapes advantage

Stop wrestling with materials that fight you at every step. Choose a lightweight, durable, and infinitely customizable cornice system—built to last, made in the USA.

Requires heavy foundations, cranes, and large crews, leading to higher costs and project delays.

Slow, labor-intensive installation is plagued by weather delays, on-site modifications, and long curing times.

Prone to cracking (concrete), rot (wood), and moisture damage (MDF), requiring constant and costly long-term maintenance.

Designs are severely limited by material weight and complexity. Custom work is prohibitively expensive and slow.

High upfront costs for materials and labor are compounded by expensive, ongoing maintenance and repairs.

Up to 90% lighter, eliminating the need for cranes or costly structural reinforcement.

Prefabricated, lightweight sections install in a fraction of the time, accelerating project timelines and reducing labor costs.

A waterproof polyurea shell makes it impervious to rot, insects, and cracking. An 80-100 year lifespan with zero maintenance required.

CNC fabrication provides total design freedom. Any profile, from modern to historic, is created with perfect precision.

Significant savings on labor, equipment, and transportation result in a lower total project cost and a smarter investment.

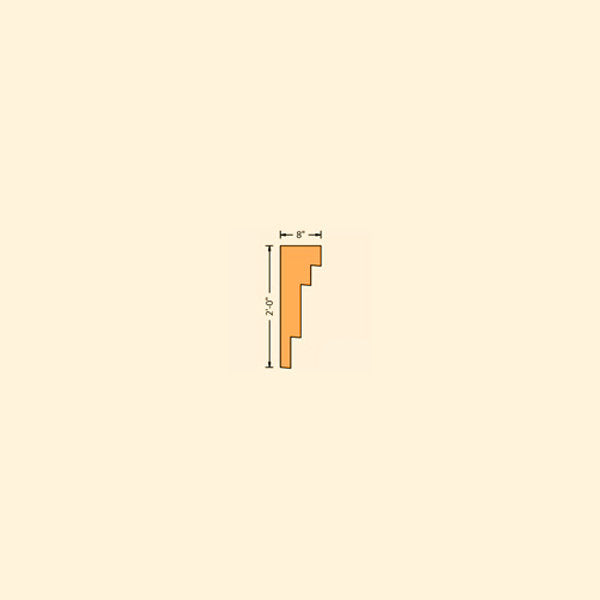

Сustom crown moldings

How to order your custom architectural molding

From your initial CAD file to job site delivery—our process is transparent, fast, and engineered for your success.

It all begins with a deep dive into your project. We work as your technical partner to transform creative intent into a solid, actionable plan.

- Analyze Your Inputs: We review your architectural plans, CAD files, sketches, and inspirational images to understand your design from every angle.

- Define the Scope: In a collaborative consultation, we discuss the project’s aesthetic goals, site conditions, and technical requirements to ensure a perfect fit.

- Establish a Technical Blueprint: We finalize all specifications, from dimensions to finish textures, creating a clear roadmap for fabrication that aligns perfectly with your vision.

We bridge the gap between concept and cost, providing you with the clarity and confidence to move forward.

- Receive a Detailed 3D Visualization: We create and send you a precise 3D model, allowing you to see exactly how your custom architectural elements will look before production begins.

- Get a Transparent, Itemized Proposal: You receive a clear, comprehensive quote with no hidden fees. We believe in total transparency, so you know exactly what you’re investing in.

- Maintain Complete Control for Final Approval: We don’t proceed until you are 100% satisfied. You have the final say on the design and budget before we move to the next stage.

This is where your approved design becomes a physical reality, crafted with an obsessive focus on quality in our 45,000 sq. ft. workshop.

- Execute with Robotic Accuracy: Our state-of-the-art CNC hot-wire machines carve your architectural elements with flawless precision, matching your approved 3D models to the exact specification.

- Armor for a Century of Performance: Our skilled artisans apply our signature Polyurea hard coat, creating a seamless, impact-resistant, and weatherproof shell designed for decades of durability.

- Verify Through Rigorous Quality Control: Every single piece undergoes a multi-point inspection to ensure it meets our exact standards for shape, finish, and structural integrity.

Our commitment extends all the way to your job site, ensuring a smooth and successful installation.

- Protect with Secure, Custom Crating: We build specialized shipping crates for every project, guaranteeing your elements arrive in pristine, ready-to-install condition.

- Streamline Your Installation: Your pieces are delivered pre-assembled and lightweight, designed to slash on-site labor time and eliminate the need for heavy machinery.

- Support Your Crew to the Finish Line: We provide detailed installation guides and offer live Zoom support to answer your team’s questions, guaranteeing a perfect final fit.

It all begins with a deep dive into your project. We work as your technical partner to translate creative intent into a solid, actionable plan.

- Analyze Your Inputs: We review your architectural plans, CAD files, sketches, and inspirational images to understand your design from every angle.

- Define the Scope: In a collaborative consultation, we discuss the project’s aesthetic goals, site conditions, and technical requirements to ensure a perfect fit.

- Establish a Technical Blueprint: We finalize all specifications, from dimensions to finish textures, creating a clear roadmap for fabrication that aligns perfectly with your vision.

We bridge the gap between concept and cost, providing you with the clarity and confidence to move forward.

- Receive a Detailed 3D Visualization: We create and send you a precise 3D model, allowing you to see exactly how your custom architectural elements will look before production begins.

- Get a Transparent, Itemized Proposal: You receive a clear, comprehensive quote with no hidden fees. We believe in total transparency, so you know exactly what you’re investing in.

- Maintain Complete Control for Final Approval: We don’t proceed until you are 100% satisfied. You have the final say on the design and budget before we move to the next stage.

This is where your approved design becomes a physical reality, crafted with an obsessive focus on quality in our 45,000 sq. ft. workshop.

- Execute with Robotic Accuracy: Our state-of-the-art CNC hot-wire machines carve your decorative architectural shapes with flawless precision, matching your approved 3D model to the millimeter.

- Armor for a Century of Performance: Our skilled artisans apply our signature Polyurea hard coat, creating a seamless, impact-resistant, and weatherproof shell designed for decades of durability.

- Verify Through Rigorous Quality Control: Every single piece undergoes a multi-point inspection to ensure it meets our exacting standards for form, finish, and structural integrity.

Our commitment extends all the way to your job site, ensuring a smooth and successful installation.

- Protect with Secure, Custom Crating: We build custom shipping crates for your elements, ensuring they arrive on-site in pristine, ready-to-install condition.

- Streamline Your Installation: Your pieces are delivered pre-assembled and lightweight, designed to slash on-site labor time and eliminate the need for heavy machinery.

- Support Your Crew to the Finish Line: We provide detailed installation guides and offer live Zoom support to answer your team’s questions, guaranteeing a perfect final fit.

Our project gallery

Engineered solutions for every architectural statement

From modern commercial facades to historic restorations, our systems are engineered to solve the unique challenges of your project.

Finally achieve the complex, multi-layered cornices from your renderings without fighting the constraints of weight and cost. We fabricate to your exact CAD files, providing the technical documentation you need to specify with confidence.

Accelerate your project timelines and reduce labor costs. Our lightweight systems allow facade work to be completed faster by smaller crews, getting you to market quicker and improving your bottom line.

Elevate your brand’s presence with a powerful architectural signature. Ideal for hotels, corporate headquarters, and high-end retail, our cornices deliver a premium look with zero long-term maintenance headaches.

Perfectly replicate ornate, historic cornices with lightweight elements that won’t compromise the integrity of an older structure. We can match any historical profile with precision.

Before and after:

From forgettable to formidable

Discover our workA crown molding is more than trim—it's your architectural signature

Your exterior cornice moulding is more than an architectural detail—it’s the signature that communicates value before anyone steps inside. We engineer crown moldings that don’t just complete a building; they elevate its worth.

- Establish Instant PrestigeOur decorative crown molding adds undeniable sophistication to your facade, projecting an image of quality and permanence that attracts premium clients and tenants.

- Engineer Out Long-Term CostsForget the endless cycle of rot, cracking, and repainting. Our high-performance crown moldings are a one-time investment in lasting curb appeal, delivering a superior return through zero maintenance.

- Define Your Architectural BrandWhether it’s a crisp, modern crown molding or a complex historical profile, we deliver custom crown molding that transforms your building into a unique and memorable landmark.

Client testimonials

From your first idea to the final installation — our process is clear, fast, and designed to make every detail simple.

FAQ

What parameters should I look at to determine whether foam crown moldings are suitable for my project?

In the majority of commercial interiors, they are an excellent fit. The dimensional stability of the material (not like wood), the lightweight construction — typically 0.6 to 1.2 pounds per foot — and the specialized reinforced protective coating make these products truly unique. They are ideal for spaces where installation precision and speed are critical.

How precise are your corners?

The corner elements we manufacture are produced using the same CNC programs as the straight sections. This ensures seam alignment with a tolerance of ±0.5 mm.

How do you match colors and shades for crown moldings?

To achieve the highest level of color accuracy, we use spectrophotometric equipment and maintain a matching tolerance below ΔE 1.5.

How fast is installation?

Usually about 165–190 linear feet in four workdays. On a particularly tight downtown site, an entire run was installed with just a small crew and no heavy equipment — and still finished ahead of schedule.

Will it feel quieter next to a busy road?

Absolutely. Most people notice the difference the first evening. The shell reflects harsh noise while the foam core absorbs the rest. At a project near a Miami expressway, the change was dramatic enough that residents started using their outdoor space again.

Can you match our façade color exactly?

Yes — we’re obsessive about that. Foam takes acrylic with precision, and we routinely achieve perfect visual matches. A historic property in Savannah once had us match an aged brick tone, and even the neighbors assumed the new wall was original masonry.

What if we have a big grade change?

No problem. Foam follows contours far more easily than concrete or masonry. Instead of awkward steps, we can create smooth transitions that maintain visual calm and proper drainage.

Will a white finish last in coastal weather?

It will if the system is specified correctly. With the right coating and finish, walls along the Gulf Coast have stayed chalk-free and color-true for years. Occasional rinsing is usually all the maintenance required.

Are foam panels strong enough for high winds?

Yes. When everything is engineered thoughtfully — from precise anchor spacing to slightly shortened modules in the most exposed spots — the fence doesn’t behave like a fragile structure, but like a seasoned sailor standing firm on deck in the middle of a storm. Even hurricane-level coastal winds don’t faze it: it doesn’t shift a millimeter, doesn’t crack, and never gives in to the elements. At one property near Daytona Beach, the fence looked as if it had been installed yesterday, even after an entire storm season — perfectly straight, steady, and untouched. It’s more than just strength; it’s a quiet confidence you can feel when you look at it, as if the architecture itself is saying, “I’m right where I belong — and I’m not going anywhere.”

Can we include a recessed logo without a billboard look?

Definitely. Because foam is so easy to shape, recessed details feel purposeful rather than forced. One Atlanta property incorporated its logo into a shadowed niche with subtle lighting — the effect is elegant by day and welcoming at night.

Is six feet high enough for privacy?

Often, yes. Especially when paired with strategic planting. And if local codes require more, we can add height without creating a fortress-like presence.

What do you need to provide a quote?

Length, height, a style cue, and a few photos. Include a color sample early and we can return strike-offs with the estimate — speeding approvals by up to a week.

We want a wood look without the upkeep.

We can achieve that easily. Slim aluminum fins paired with textured foam surfaces create the warmth and light play of wood without rot, refinishing, or fading. On one residential project, the “wood” still looked fresh three seasons later with nothing more than a garden hose rinse. The result was as visually appealing as natural wood and perfectly matched the desired look of the homeowner.

& specification catalog

Get the definitive guide to our custom decorative architectural foam shapes. This free catalog is packed with hundreds of design profiles, detailed technical specifications, and real-world project applications.

Have a project in mind?

Our dedicated specialists are ready to collaborate with you, turning your concept into a detailed plan with a transparent budget. Let’s bring your vision to life!

More architectural shapes

We provide architects, builders, and homeowners with turnkey decorative elements that transform any project — fast, easy, and cost-effective.

Crown moldings

Our decorative molding profiles are manufactured in the United States, at our facility in Florida, which allows us to control every stage of production. When we provide a 20-year warranty, we do so with full confidence, knowing that our products can truly perform for those 20 years when properly installed and maintained.

We deliver fully finished architectural components — ready for installation, pre-painted, coated with protective layers, and fabricated with geometric precision up to 0.5 mm. Stable in terms of geometry, capable of handling loads, and requiring virtually no additional effort during installation. Architects, contractors, and developers all appreciate this level of predictability when working with foam-based architectural components. This is especially important on large projects where significant volumes of molding must be installed and where stability, consistency, and the absence of on-site trimming or modifications are critical. It allows teams to achieve maximum results with minimal labor and minimal installation time.

Architectural foam is inherently stable and behaves predictably across a wide range of conditions. Whether exposed to fluctuating temperatures, prolonged direct UV radiation, high humidity, or strong winds, the geometry of architectural foam remains accurate, and the exterior appearance of the product does not deteriorate.

The specialized protective coating further extends the material’s longevity without altering its performance characteristics. Architectural foam components can reliably serve for up to 20 years — a duration we confidently guarantee because we stand firmly behind the quality of every product we manufacture.

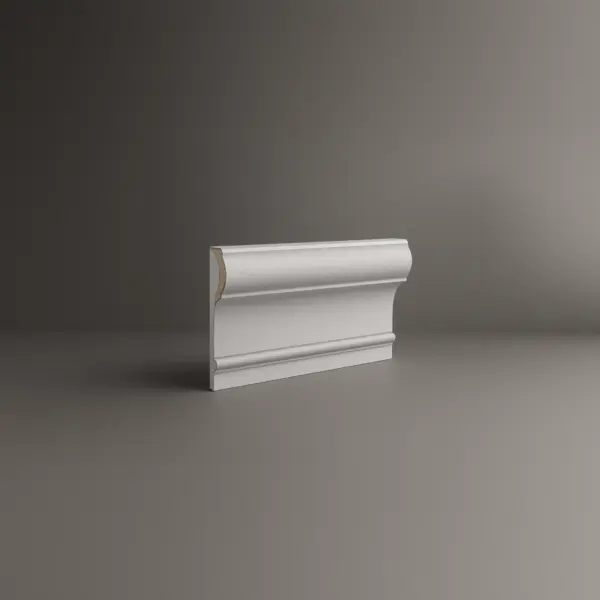

The modern profile of a crown molding

Modern crown moldings are engineered building components. They must meet performance expectations like any other architectural element. Foam allows us to meet these expectations with repeatable precision:

- predictable thermal behavior;

- extremely low expansion and shrinkage rates;

- stable geometry even on long sections;

- detailed surface textures with 0.2–0.5 mm accuracy;

- corner joints aligned to CNC tolerances.

Our decorative crown molding corners are produced under the same calibration settings as the straight sections, so the geometry matches across every batch. And our custom crown molding capability ensures we can replicate any architectural profile with tolerances that older materials simply cannot match.

Material technology and engineering standards of crown moldings

| Technical Domain | Specific Attribute | Measured Range / Value | Engineering Interpretation |

|---|---|---|---|

| Core Structural Matrix | Density spectrum | ~18.5–29.7 lb/ft³ | Density is selected based on span length, profile elevation, and stiffness requirements. |

| Compression Load Endurance | Test protocol (ASTM D1621 equivalent) | 18–25 psi | Ensures the core maintains form during handling and installation stresses. |

| Exterior Composite Shield | Reinforced coating thickness | ~2.1–4.3 mm | Polymer-cement skin with fiberglass micro-mesh dramatically increases impact resistance. |

| Flexural Response Capacity | Bending strength | 40–55 psi | Prevents micro-fracturing on extended profile sections. |

| Digital Geometry Precision | CNC machining tolerance | ±0.45–1.0 mm | Stability is preserved across batches due to unaltered digital toolpaths. |

| Thermal Movement Behavior | Linear expansion coefficient | <0.01% per 10°F | Allows 20–30 ft continuous runs to remain visually straight without bowing. |

| Factory Finish System | Dual-layer acrylic coating | 2–3 mils | Eliminates all field finishing or priming activities. |

| Linear Weight Profile | Weight per foot | 0.6–1.2 lb/ft | 8–12 times lighter than gypsum, significantly reducing load on framing. |

| Production Length Options | Supplied lengths | 96–144 in (±1/16 in) | Extended lengths available for lobbies, atriums, and long corridor applications. |

| Corner Coherence Precision | CNC-aligned corner geometry | ±0.5 mm | Produces virtually invisible seam transitions at normal viewing distances. |

| Hydro-Barrier Performance | Moisture resistance | ≥98%, zero capillarity | No swelling, mold formation, or material softening. |

| Water Absorption Index | ASTM C272 | <1% by volume | Performs reliably in high-humidity regions such as coastal Florida. |

| Combustion Behavior | Flame classification | Class A (ASTM E84) | Flame spread index ≤25; suitable for hotels, hospitals, schools. |

| Surface Hardness Metric | Shore scale | D 55–60 | Comparable to high-performance architectural polymer finishes. |

| Dimensional Longevity | Seasonal shrinkage | <0.1% | Maintains geometric integrity across temperature cycles. |

| Color Precision Factor | Spectrophotometric delta | ΔE < 1.5 | Ensures visual compatibility with trims and wall systems. |

| Adhesive Bond Capacity | ASTM C297 | 18–25 psi | Compatible with commercial adhesives; delivers strong structural adhesion. |

| Acoustic Reflection Response | Resonance behavior | Low | Reduces flutter echo in extended hallways. |

| Thermal Operating Envelope | Approved temperature range | –20°F to +120°F | Geometry remains stable in both cold and hot environments. |

| Substrate Compensation Tolerance | Wall/ceiling deviation limit | Up to 3 mm | Adhesive layer eliminates the need for additional surface preparation. |

| Installation Output Rate | Linear install speed | 25–35 ft/hr (single installer) | No wet trades required; dramatically accelerates project timelines. |

| Curved Geometry Capabilities | Radius availability | 24–60 in | Digitally shaped radius profiles for custom curvature requirements. |

| Quality Assurance Framework | 7-stage QC protocol | — | All batches digitally logged and cross-checked. |

| Inventory Services | Complimentary storage | Up to 6 months | Climate-controlled warehousing keeps product stable. |

| Shipping Protection Design | Multi-layer packaging system | — | Foam layering + reinforced corner guards for long-haul protection. |

| Warranty Statement | Performance guarantee | 20-year warranty | Covers geometry retention and coating integrity. |

| Production Origin | Manufacturing location | USA, Florida | Full domestic production control and traceability. |

Design evolution architectural elements, including foam crown moldings

Today, the market for architectural elements especially of crown moldings has changed dramatically. Ten or twenty years ago, classical decorative components dominated, but now the trend has shifted toward minimalist, clean, and simple architectural forms—and crown moldings are no exception. At the same time, we’ve noticed that our clients increasingly seek customized, unique pieces and come to us knowing we can deliver exactly what they envision. They choose clean, geometric, minimalist lines, yet still want their architectural elements to feature a small distinctive detail or visual accent. We can easily bring these ideas to life—whether by creating the accent ourselves or by working from the client’s sketches, drawings, or photos.

Foam-based architectural components are exceptionally well suited for these kinds of requests. One of our recent large-scale projects, where we produced a significant volume of crown moldings, clearly demonstrated this advantage. Installation teams expressed their appreciation for the fact that clients selected foam elements, as the installation time was reduced by 20–30%. And even with a 12-foot crown molding, a single installer could handle the piece without assistance—because each one weighs less than 15 pounds.

Applications and profile types of crown moldings

Modern profiles of crown moldings

Used in virtually any type of interior — business environments, private homes, and public institutions. Anywhere geometric precision is required and where the interior needs to look complete and visually harmonious.

Decorative architectural crown moldings

For example, we once produced architectural elements for a lobby in St. Petersburg, Florida, and that project clearly demonstrated how decorative foam crown moldings—seemingly a small detail—can soften the geometry of a space, add visual accents, and bring the entire interior together into a more harmonious, cohesive environment.

Custom-engineered crown moldings

Are designed specifically for each project. We often work with designers, architects, and developers who come to us because they need a special geometry, a unique shape, or something out of the ordinary. In such cases, the priority shifts from aesthetics to engineering. We create a 3D file where we verify the alignment of all lines and joints, test the required radii, and only then proceed to shaping the visual design. This approach completely eliminates installation challenges on site and allows the decorative elements to be mounted quickly and seamlessly.

Installation and maintenance of crown moldings — expanded, technical, step-by-step

Installation of foam crown moldings is a controlled technical process, not guesswork.

| # | Installation Step | Technical Process and Advantages |

|---|---|---|

| 1 | Substrate evaluation | If the surface deviation ranges within 1–3 mm, this is completely normal, especially in commercial architectural projects. Foam crown moldings easily compensate for such variations and do not require any additional intervention or surface leveling. |

| 2 | Dry alignment | Installers first position the profiles without any adhesive, and once they confirm that the CNC-cut ends fit together perfectly, they apply the adhesive and secure the architectural elements in place. This approach reduces installation time by approximately 20–30%. |

| 3 | Adhesive bead application | Precision application of structural adhesive to the mounting surfaces to ensure a permanent bond with the substrate. |

| 4 | Mechanical fixation | Because the elements are very lightweight, there is no need for complex fastening systems. Light temporary pins are sufficient to hold the pieces in place until the adhesive cures. |

| 5 | Joint finishing | The foam has a highly uniform texture, which means that even untreated joints remain barely noticeable, as the gaps are minimal. The reinforced protective coating further reduces the visibility of these joints, allowing them to blend in as much as possible. |

| 6 | Final cleanup | No sanding, filling, priming, or painting. The factory-applied dual-coat acrylic finish is ready for immediate use. |

Maintenance

The coating resists micro-cracking because its flexural strength accommodates building vibrations. Even after 10–15 years, installations we’ve revisited show no signs of discoloration or deformation.

Why partners rely on us — expanded, engineering-focused version

Clients choose us because we provide engineered certainty. Every element is manufactured in our U.S. facility under controlled conditions. This means no supply chain unpredictability, no variable quality between batches, and no long-distance import delays. Our facilities operate with digital profile libraries, precise CNC routing, automated paint metering systems ensuring consistent coat thickness, and structured QC logs.

Design teams rely on our accuracy. When they specify a profile height of 5⅝ inches, they receive exactly 5⅝ inches ±0.5 mm — not an approximation. When they request a custom texture, we replicate it with controlled depth. When they bring a physical finish sample, we match it with ΔE < 1.5 color accuracy.

Construction teams especially appreciate that foam architectural elements are extremely easy to install—their low weight eliminates the need for specialized equipment or advanced technical skills. Developers, in turn, value the fact that by choosing foam architectural components, they can be confident they will stay within budget, meet project deadlines, and achieve a flawless visual result.

Our ability to combine striking, visually compelling design with precise engineering solutions is the foundation of the long-lasting partnerships we build with our clients — relationships that are never just one-off. And the 20-year warranty we provide for our architectural elements further emphasizes that when you choose our products, you are investing not simply in an item, but in a high-quality solution that will perform reliably for years.

Architectural elements, by their very nature, are not just small decorative accents. They also serve a number of practical functions essential for achieving a cohesive and well-designed interior. They can conceal mechanical and electrical systems and help unify the space, contributing to a balanced and intentional visual effect.

Our foam crown moldings are lightweight and can be color-matched with exceptional accuracy since we offer fully customized solutions. They are also thermally stable, and the fact that they are manufactured in the United States allows us to maintain full control over every stage of production. This gives us complete responsibility for compliance with building, fire-safety, and architectural standards.

In addition, because our manufacturing facility is located in Florida, we can reliably reproduce architectural elements in any quantity required. All specifications, drawings, geometries, color formulas, and surface textures remain stored in our internal database, making repeat orders fast, consistent, and seamless.

Our production methods, technical support, and material quality testing ensure that every crown molding precisely matches the design geometry and fully complies with performance and durability requirements. Whether the project calls for clean modern minimalism, a more traditional classic look (like wood or stone), or distinctive decorative detailing with custom geometry, we provide solutions that stay true to the original design intent.

If you would like a project estimate, simply send us a photo, drawing, or sample — we will prepare a detailed quotation for you as quickly as possible.

& specification catalog

Get the definitive guide to our custom decorative architectural foam shapes. This free catalog is packed with hundreds of design profiles, detailed technical specifications, and real-world project applications.

Have a project in mind?

Our dedicated specialists are ready to collaborate with you, turning your concept into a detailed plan with a transparent budget. Let’s bring your vision to life!