About our architectural capital and base systems

We’ve engineered away the weight and complexity, leaving only pure architectural expression.

From Structural Post to Architectural Statement

Timeless, elegant, and structurally brilliant—our architectural capitals and bases are crafted from a high-density, lightweight composite system to replicate solid, load-bearing masonry without the engineering nightmare. Perfect for grand entrances, colonnades, and interior accents, these systems add a powerful statement of authority and sophisticated design.

Each architectural column consists of three precision-made parts:

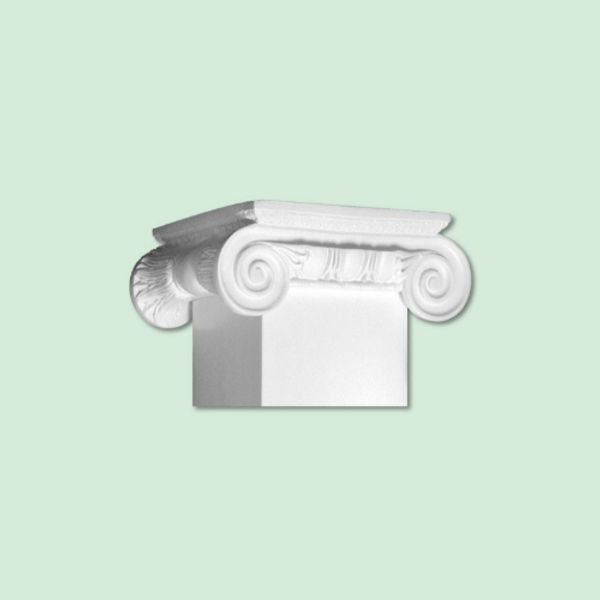

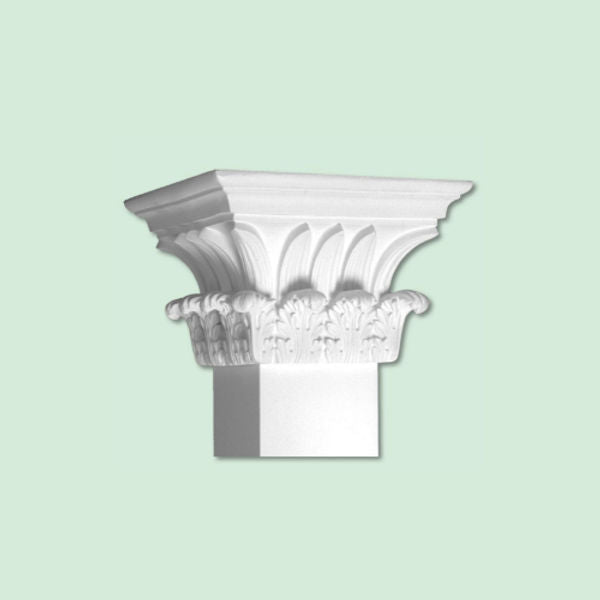

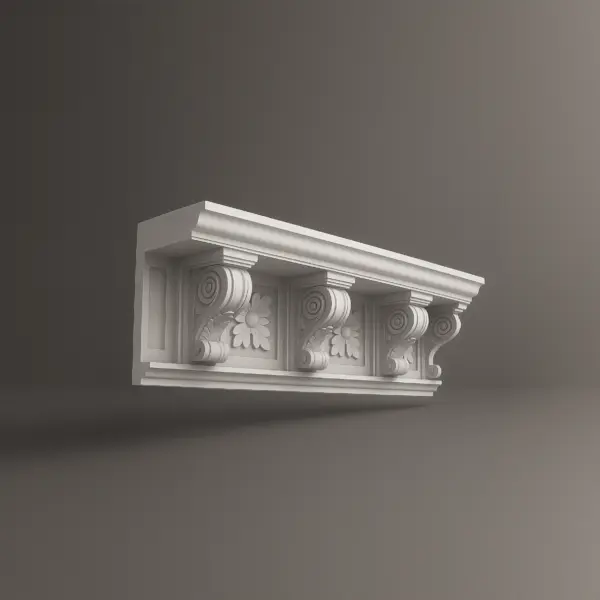

- Column Capital: The crowning element, available in any style from Doric to Corinthian, or custom-designed to your exact specifications. This is where architectural vision comes to life.

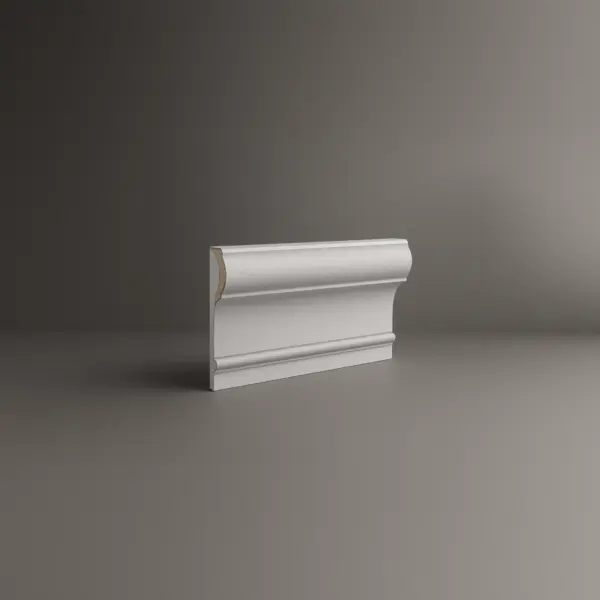

- Base: The foundational element that provides visual stability and completes the column’s aesthetic. We offer classic styles like the Attic Column Base and Doric Column Base, or fully custom profiles.

- Shaft (Wrap): The body of the column, designed to seamlessly clad existing structural supports, transforming simple posts into magnificent architectural features.

Get a modular system that installs with absolute precision.

The science behind a flawless column finish

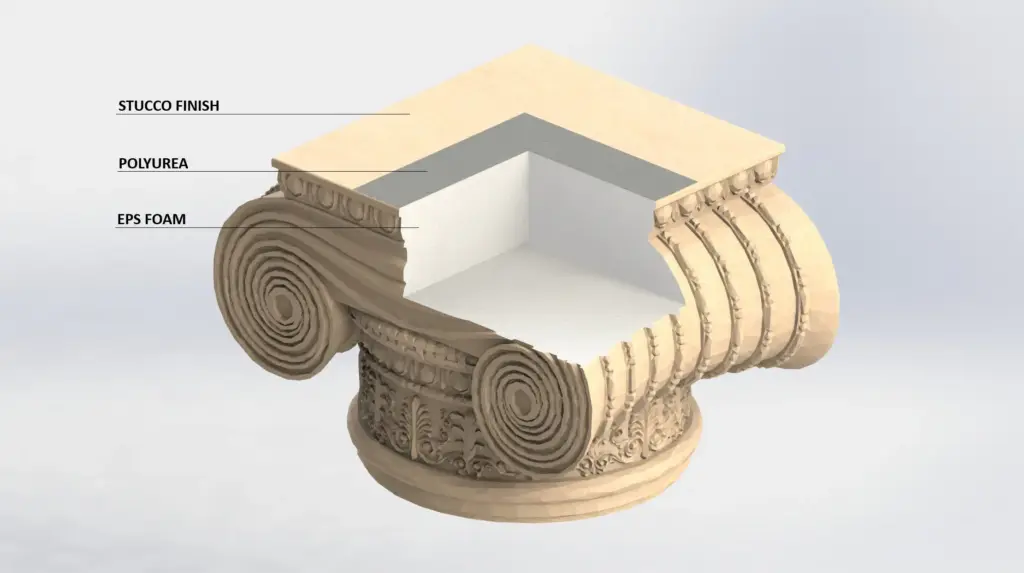

Our architectural column systems are built from an advanced composite of materials engineered for aesthetic perfection and extreme longevity. At the core is a structural, high-density Expanded Polystyrene (EPS) foam, which is precision-cut with CNC technology to ensure every volute, acanthus leaf, and fillet is flawlessly executed.

This core is then fully encapsulated in our signature polyurea hard coat. This spray-applied elastomer creates a seamless, waterproof, and impact-resistant exoskeleton, transforming the lightweight foam into a monolithic structure with incredible strength and durability.

The exterior is an integrated, architectural-grade finish that provides the authentic texture of stone, plaster, or precast concrete and offers superior resistance to weathering, UV degradation, and cracking. This advanced construction makes our column capital and base systems robust, elegant, and built to last for generations.

Assortment of custom capitals and bases

EPS foam vs. traditional materials:

the Decorative Architectural Shapes advantage

Stop letting heavy, outdated materials dictate your design and budget. Choose lightweight, durable, and fully customizable capitals and bases—built to last, made in the USA.

Requires a crane, a large crew, and a reinforced foundation just to move and place.

Held hostage by weather delays, mortar curing times, and slow, heavy labor.

Prone to cracking from freeze-thaw cycles, water damage, and staining. Requires constant upkeep.

Limited by standard molds or the extreme cost and time of hand-carving.

High upfront costs are compounded by ongoing expenses for maintenance and repairs.

Eliminates the need for heavy machinery and costly structural reinforcement.

A small crew can get the job done fast, accelerating your entire project timeline.

Waterproof shell resists cracking, mold, and rot. Built to last a century.

Achieve any level of complexity and historical accuracy with total design freedom.

Dramatically lower costs for labor, equipment, shipping, and long-term ownership.

Сustom capitals and bases

How to order architectural capitals and bases

From your CAD file to final installation—our process is transparent, collaborative, and engineered for architectural precision.

It all begins with a deep dive into your project. We work as your technical partner to transform creative intent into a solid, actionable plan.

- Analyze Your Inputs: We review your architectural plans, CAD files, sketches, and inspirational images to understand your design from every angle.

- Define the Scope: In a collaborative consultation, we discuss the project’s aesthetic goals, site conditions, and technical requirements to ensure a perfect fit.

- Establish a Technical Blueprint: We finalize all specifications, from dimensions to finish textures, creating a clear roadmap for fabrication that aligns perfectly with your vision.

We bridge the gap between concept and cost, providing you with the clarity and confidence to move forward.

- Receive a Detailed 3D Visualization: We create and send you a precise 3D model, allowing you to see exactly how your custom architectural elements will look before production begins.

- Get a Transparent, Itemized Proposal: You receive a clear, comprehensive quote with no hidden fees. We believe in total transparency, so you know exactly what you’re investing in.

- Maintain Complete Control for Final Approval: We don’t proceed until you are 100% satisfied. You have the final say on the design and budget before we move to the next stage.

This is where your approved design becomes a physical reality, crafted with an obsessive focus on quality in our 45,000 sq. ft. workshop.

- Execute with Robotic Accuracy: Our state-of-the-art CNC hot-wire machines carve your architectural elements with flawless precision, matching your approved 3D models to the exact specification.

- Armor for a Century of Performance: Our skilled artisans apply our signature Polyurea hard coat, creating a seamless, impact-resistant, and weatherproof shell designed for decades of durability.

- Verify Through Rigorous Quality Control: Every single piece undergoes a multi-point inspection to ensure it meets our exact standards for shape, finish, and structural integrity.

Our commitment extends all the way to your job site, ensuring a smooth and successful installation.

- Protect with Secure, Custom Crating: We build specialized shipping crates for every project, guaranteeing your elements arrive in pristine, ready-to-install condition.

- Streamline Your Installation: Your pieces are delivered pre-assembled and lightweight, designed to slash on-site labor time and eliminate the need for heavy machinery.

- Support Your Crew to the Finish Line: We provide detailed installation guides and offer live Zoom support to answer your team’s questions, guaranteeing a perfect final fit.

It all begins with a deep dive into your project. We work as your technical partner to translate creative intent into a solid, actionable plan.

- Analyze Your Inputs: We review your architectural plans, CAD files, sketches, and inspirational images to understand your design from every angle.

- Define the Scope: In a collaborative consultation, we discuss the project’s aesthetic goals, site conditions, and technical requirements to ensure a perfect fit.

- Establish a Technical Blueprint: We finalize all specifications, from dimensions to finish textures, creating a clear roadmap for fabrication that aligns perfectly with your vision.

We bridge the gap between concept and cost, providing you with the clarity and confidence to move forward.

- Receive a Detailed 3D Visualization: We create and send you a precise 3D model, allowing you to see exactly how your custom architectural elements will look before production begins.

- Get a Transparent, Itemized Proposal: You receive a clear, comprehensive quote with no hidden fees. We believe in total transparency, so you know exactly what you’re investing in.

- Maintain Complete Control for Final Approval: We don’t proceed until you are 100% satisfied. You have the final say on the design and budget before we move to the next stage.

This is where your approved design becomes a physical reality, crafted with an obsessive focus on quality in our 45,000 sq. ft. workshop.

- Execute with Robotic Accuracy: Our state-of-the-art CNC hot-wire machines carve your decorative architectural shapes with flawless precision, matching your approved 3D model to the millimeter.

- Armor for a Century of Performance: Our skilled artisans apply our signature Polyurea hard coat, creating a seamless, impact-resistant, and weatherproof shell designed for decades of durability.

- Verify Through Rigorous Quality Control: Every single piece undergoes a multi-point inspection to ensure it meets our exacting standards for form, finish, and structural integrity.

Our commitment extends all the way to your job site, ensuring a smooth and successful installation.

- Protect with Secure, Custom Crating: We build custom shipping crates for your elements, ensuring they arrive on-site in pristine, ready-to-install condition.

- Streamline Your Installation: Your pieces are delivered pre-assembled and lightweight, designed to slash on-site labor time and eliminate the need for heavy machinery.

- Support Your Crew to the Finish Line: We provide detailed installation guides and offer live Zoom support to answer your team’s questions, guaranteeing a perfect final fit.

Our project gallery

Engineered solutions

for every architectural style

Engineered for the visionaries who design, the experts who build, and the leaders who own.

Realize your most ambitious designs without compromise. We fabricate any of the historical column capital types—from the simplicity of Doric to the complexity of Composite—or your unique, modern creations to your exact CAD specifications. We provide the tools to build what was previously deemed “unbuildable.”

Accelerate project timelines and enhance property value. Our lightweight systems allow you to add high-end architectural grandeur that attracts premium tenants and buyers, all while staying ahead of schedule and under budget.

Create an unforgettable first impression that communicates authority and prestige. Ideal for banks, hotels, corporate headquarters, and luxury retail, our column systems require zero maintenance and are built to withstand the test of time.

Achieve the timeless elegance of a classic estate. Our systems provide the perfect solution for creating a grand entryway, a stunning portico, or a classic garden rotunda that adds significant curb appeal and lasting value.

From underwhelming to unforgettable

Discover our workHow our column capitals elevate your architectural presence

A column capital is more than just the top parts of a column capital—it’s the signature of a building’s design language. It communicates intent, style, and a commitment to quality. An engineered capital and base system from Decorative Architectural Shapes instantly elevates your project from ordinary to extraordinary.

- Communicate Authority and PrestigeA well-executed capital column adds a sense of permanence, history, and quality. It demonstrates an investment in detail that builds trust and confidence with clients, visitors, and investors alike.

- Durable by Design, Smart by EconomicsUnlike stone or concrete that cracks and stains, our polyurea-coated systems are engineered to be impervious to weather, UV rays, and time—staying pristine year after year with zero maintenance. This low total cost of ownership is a smart investment for any high-value property.

- Custom Design for a Unique IdentityYour building should tell a story. With the ability to replicate any historical style or create entirely new forms, our systems can be tailored to align perfectly with your project's architectural vision and brand identity, ensuring a truly unique and memorable result.

Client testimonials

From your first idea to the final installation — our process is clear, fast, and designed to make every detail simple.

FAQ

How fast is installation?

Usually about 165–190 linear feet in four workdays. On a particularly tight downtown site, an entire run was installed with just a small crew and no heavy equipment — and still finished ahead of schedule.

Will it feel quieter next to a busy road?

Absolutely. Most people notice the difference the first evening. The shell reflects harsh noise while the foam core absorbs the rest. At a project near a Miami expressway, the change was dramatic enough that residents started using their outdoor space again.

Can you match our façade color exactly?

Yes — we’re obsessive about that. Foam takes acrylic with precision, and we routinely achieve perfect visual matches. A historic property in Savannah once had us match an aged brick tone, and even the neighbors assumed the new wall was original masonry.

What if we have a big grade change?

No problem. Foam follows contours far more easily than concrete or masonry. Instead of awkward steps, we can create smooth transitions that maintain visual calm and proper drainage.

Will a white finish last in coastal weather?

It will if the system is specified correctly. With the right coating and finish, walls along the Gulf Coast have stayed chalk-free and color-true for years. Occasional rinsing is usually all the maintenance required.

Are foam panels strong enough for high winds?

Yes. When everything is engineered thoughtfully — from precise anchor spacing to slightly shortened modules in the most exposed spots — the fence doesn’t behave like a fragile structure, but like a seasoned sailor standing firm on deck in the middle of a storm. Even hurricane-level coastal winds don’t faze it: it doesn’t shift a millimeter, doesn’t crack, and never gives in to the elements. At one property near Daytona Beach, the fence looked as if it had been installed yesterday, even after an entire storm season — perfectly straight, steady, and untouched. It’s more than just strength; it’s a quiet confidence you can feel when you look at it, as if the architecture itself is saying, “I’m right where I belong — and I’m not going anywhere.”

Can we include a recessed logo without a billboard look?

Definitely. Because foam is so easy to shape, recessed details feel purposeful rather than forced. One Atlanta property incorporated its logo into a shadowed niche with subtle lighting — the effect is elegant by day and welcoming at night.

Is six feet high enough for privacy?

Often, yes. Especially when paired with strategic planting. And if local codes require more, we can add height without creating a fortress-like presence.

What do you need to provide a quote?

Length, height, a style cue, and a few photos. Include a color sample early and we can return strike-offs with the estimate — speeding approvals by up to a week.

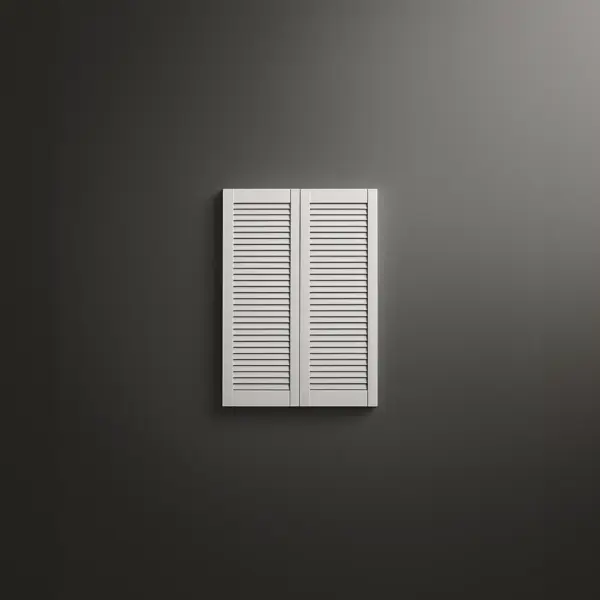

We want a wood look without the upkeep.

We can achieve that easily. Slim aluminum fins paired with textured foam surfaces create the warmth and light play of wood without rot, refinishing, or fading. On one residential project, the “wood” still looked fresh three seasons later with nothing more than a garden hose rinse. The result was as visually appealing as natural wood and perfectly matched the desired look of the homeowner.

& specification catalog

Get the definitive guide to our custom decorative architectural foam shapes. This free catalog is packed with hundreds of design profiles, detailed technical specifications, and real-world project applications.

Have a project in mind?

Our dedicated specialists are ready to collaborate with you, turning your concept into a detailed plan with a transparent budget. Let’s bring your vision to life!

More architectural shapes

We provide architects, builders, and homeowners with turnkey decorative elements that transform any project — fast, easy, and cost-effective.

Custom Capitals and Bases

Some architectural details (may be column capitals) are impossible to ignore. They don’t just decorate a building — they complete it. Column capitals are the final chord of a symphony, the detail that turns an ordinary project into something memorable and iconic. Column capital and column base are precisely those details in classical architecture.

But while in the past they were chosen from a catalog and adapted to the project, today they’ve become part of a broader strategy. Column capitals can raise the value of a building, shape how the market perceives it, emphasize the strength of a brand, or transform a standard facade into an architectural statement.

With more than 25 years in this industry, we’ve watched approaches, tastes, and technologies evolve. And one thing has remained constant: the most successful projects are those where details (like column capitals) are designed not just for aesthetics, but to solve real business tasks — shortening construction timelines, reducing costs, improving ROI, strengthening brand perception, and creating market visibility.

One example is a business center in Tampa. The client’s request was crystal clear: “We don’t want standard Corinthian capital or Doric columns. We need a presence — something solid, trustworthy, and premium.” We designed custom column capitals with refined neoclassical geometry, finished column capitals to resemble limestone, and integrated them seamlessly into the facade system. The result? The project received city approval on the first submission and was sold 14% above its projected value — even before completion.

That’s the power of detail: when design stops being decoration and becomes a strategic business tool.

From antiquity to the 21st century: how history shapes modern architecture

Every time we design a column capital, we’re not just creating a decorative element — we’re picking up a conversation that started more than 2,500 years ago. And it’s a long, fascinating conversation. The ancient Greeks, for instance, didn’t make their choices randomly. The sturdy, no-nonsense Doric columns or Corinthian columns weren’t just blocks of stone — they were a statement: this building will stand forever. Stability. Strength. Authority.

Then came the Ionic capitals — more graceful, more thoughtful, like a philosopher’s argument carved in stone. Their swirling volutes weren’t there for beauty alone; column capitals whispered of proportion, of balance, of a world where everything has its rightful place. And of course, the Corinthian capital — extravagant, ornate, unapologetically grand. Column capital shouted wealth and power before you even stepped inside.

Fast-forward a couple of millennia. The tools are different now — CAD models instead of chisels, foam instead of marble — but the language? It’s still the same. A bold, simplified Doric capital on a corporate headquarters says, “We’re here to stay.” Sleek Ionic capitals on a residential façade hint at refinement, taste, a certain intellectual elegance. And a stripped-back, minimalist column capital? That’s the vocabulary of innovation, of forward-thinking design, of a brand that doesn’t just follow trends but sets them.

We’re not just copying history. We’re remixing it — turning timeless architectural symbols into messages that still speak loudly and clearly today. We often say that every column is like an architect’s signature on the façade. The tools have changed — from chisels and hammers to CAD modeling and 3D fabrication — but the essence remains the same. And in classical architecture, these details (like column capitals) continue to define how we read and experience space.

Why foam is the material of choice

In the past, column capitals were carved from stone, cast in concrete, or welded in metal. Strong — yes. But heavy, expensive, and difficult to customize. Foam changed the game. It’s lightweight yet strong, easy to shape but highly durable. It can be painted, molded, textured — and no one will ever guess it isn’t stone or bronze.

- Up to 6–8 times lighter than traditional materials.

- Resistant to moisture, UV, and temperature fluctuations.

- Easily formed into complex, fully custom column capital types.

- Shorter installation times and lower logistics costs.

Foam also gives us unparalleled freedom. At a museum project in Savannah, where historical authenticity was paramount, we recreated 19th-century column capitals from archival sketches — with accurate travertine texture and perfect proportions. The only difference? Column capitals weighed 12 times less, and installation took five days instead of a month.

How a custom solution is born

Creating custom capitals isn’t about “taking something off the shelf.” It’s a collaborative, creative process. We begin by discussing your goals — the style, the message, the business objectives you want your architecture to express. Then we move to 3D modeling, where every curve and contour is engineered with precision. Next comes material and color matching: sometimes clients send us a piece of cladding or a tile fragment, and we match the color and texture exactly, so every detail integrates seamlessly.

Before we ever cut a single piece of foam, we bring your idea to life in a way you can touch and see. We don’t treat prototyping as a formality — for us, it’s almost a scientific ritual. Before we even think about production, we build a complete 3D model. It helps us fine-tune, question, adjust, and only then proceed, confident that what’s being fabricated aligns with your expectations.

Sometimes this step sparks unexpected ideas — maybe the profile needs a sharper edge, or the patina would look richer with a slightly warmer tone. We welcome those moments because they’re what turn a good result into an exceptional one. Only once every detail feels right — to you and to us — do we begin fabrication. And by the time installation day comes, there are no surprises, no last-minute compromises. Just exactly what you imagined, brought to life down to the millimeter.

Where our solutions are used

Commercial projects

In business, architecture speaks volumes. Column capitals add credibility and presence to office buildings, hotels, retail spaces, and restaurants. One Orlando client came to us for a simple facade detail — we proposed a more complete solution, and the result significantly boosted visibility and customer traffic.

Residential developments and private homes

Architecture here is about emotion. People want to live in a home they’re proud of. A developer in St. Augustine originally came to us for a foam fence but left with a comprehensive solution: custom column capitals and bases, window trims, and decorative panels. The project looked twice as expensive as it actually was — and units sold significantly faster than competitors.

Restoration and heritage buildings

Foam is a lifesaver when every ounce of weight matters. For a 1923 public library in Georgia, we recreated original Corinthian columns based on historical drawings. To the eye, column capitals were indistinguishable from the originals — but in reality, they’re lightweight, load-free, and extend the building’s lifespan by decades.

Temporary and event structures

Foam installs quickly and removes easily. For an exhibition pavilion in Miami, decorative columns with column capitals were installed in just six hours, delivering the grandeur of classical architecture without budget overruns or timeline delays.

Project workflow: more than manufacturing

| Этап | Описание процесса |

|---|---|

| Deep project analysis | We dive into the details — style, load, climate, installation constraints. |

| Concept & design | We create a 3D model, renderings, and material/color proposals. |

| Prototyping | You review and approve a drawing before production. |

| Manufacturing | Every detail is produced with precision at our U.S. facility. |

| Quality control | We treat every column capital as if it were going to be installed on our own building — which means meticulous inspection at every stage. Each piece goes through a **12-point quality protocol**, from dimensional accuracy and surface finish to structural integrity and weather resistance. We don’t just “check the box”; we run stress simulations, inspect coatings under different light, and even verify how the texture reacts to temperature changes. By the time a component leaves our facility, it’s already passed more tests than most materials face during their entire lifetime on-site. |

| Logistics | Think of delivery not as the last step, but as part of the design itself. The shipments are planned with the same care that is given to production — they are **mapped to your construction schedule** so components arrive exactly when they’re needed, not weeks early to clutter the site or days late to delay progress. Our logistics team coordinates with shipping brokers and your site managers, breaking deliveries into optimized batches and tracking them in real time. It’s a bit like choreography — everything arrives on cue, perfectly timed for installation. |

| On-site support | Our involvement doesn’t end once the crates are unloaded. We remain by your side, guiding installation teams, answering technical questions, and solving unexpected challenges before they become problems. If something shifts in the field — a dimension, a detail, a weather delay — we are ready to assist in real time. Think of us less as a supplier and more as part of your construction crew, dedicated to making sure every capital fits perfectly and the project moves forward without a hitch. |

More than fabrication:

how our passion, precision, and creativity fuel your success

Because we don’t just make architectural elements — we live and breathe architecture.

We are passionate about every detail, every project. We thrive on complexity and innovation. We help architects turn bold ideas into reality — and we do it with precision, on time, within budget, and without stress.

- Over 25 years of experience transforming architectural details into competitive advantages.

- U.S.-based production for total quality and schedule control.

- Solutions tailored to specific business needs — not generic catalog products.

- 100% customization — any style, shape, texture, or finish.

- Full project support — from concept to installation.

- Solutions that boost ROI — increasing property value, accelerating sales, and strengthening brand perception.

& specification catalog

Get the definitive guide to our custom decorative architectural foam shapes. This free catalog is packed with hundreds of design profiles, detailed technical specifications, and real-world project applications.

Have a project in mind?

Our dedicated specialists are ready to collaborate with you, turning your concept into a detailed plan with a transparent budget. Let’s bring your vision to life!