Architectural trim that works as hard as It looks

This is where high-end aesthetics meet rugged, zero-maintenance performance, engineered to bring your vision to life.

Architectural trim that defines, not just decorates

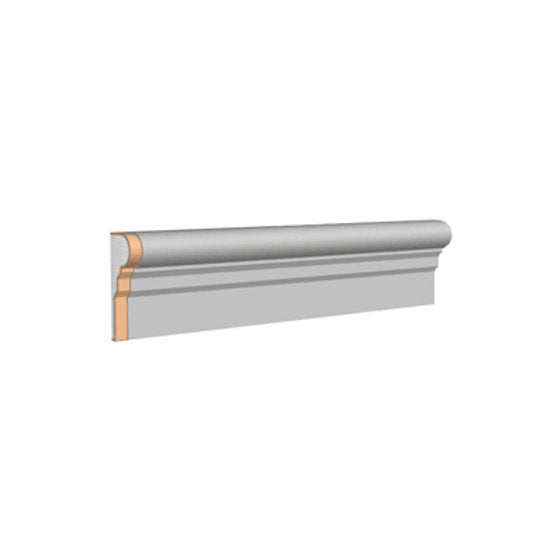

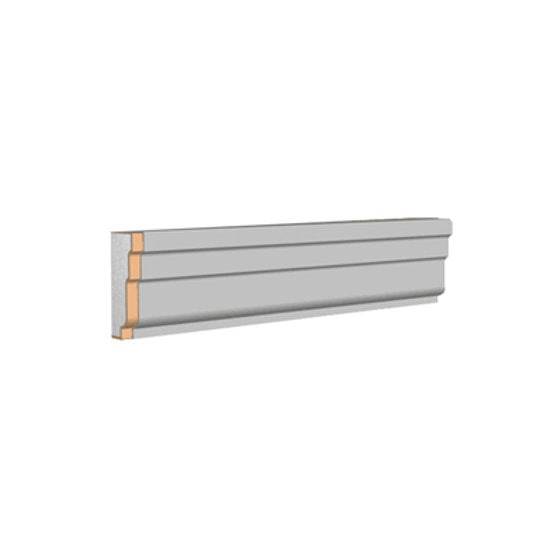

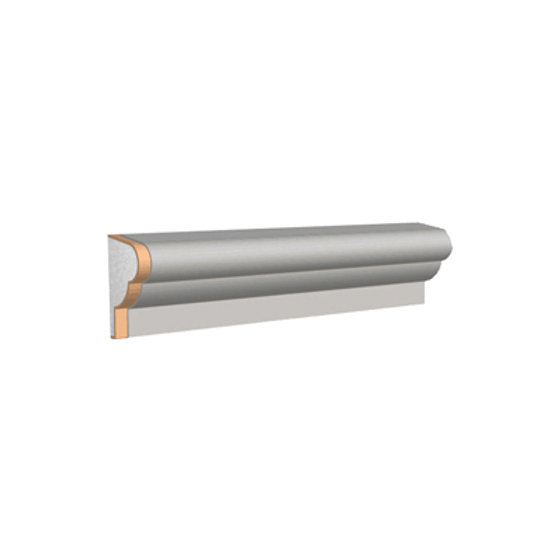

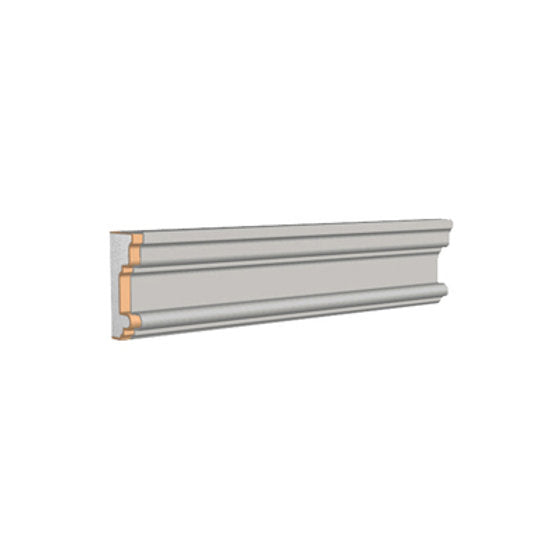

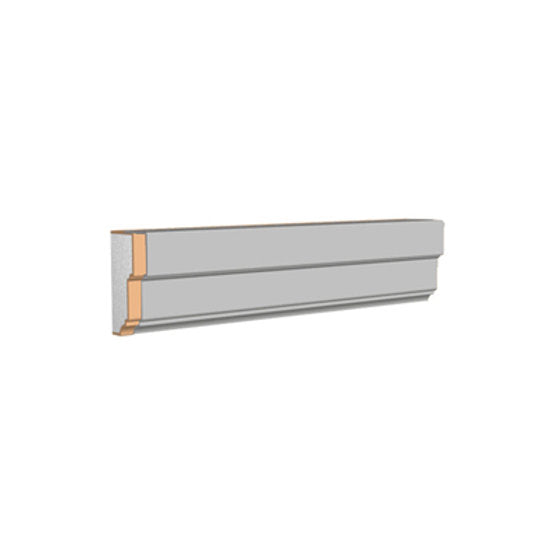

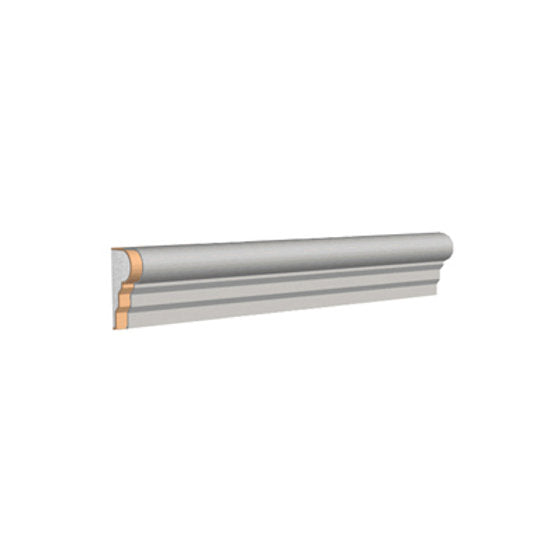

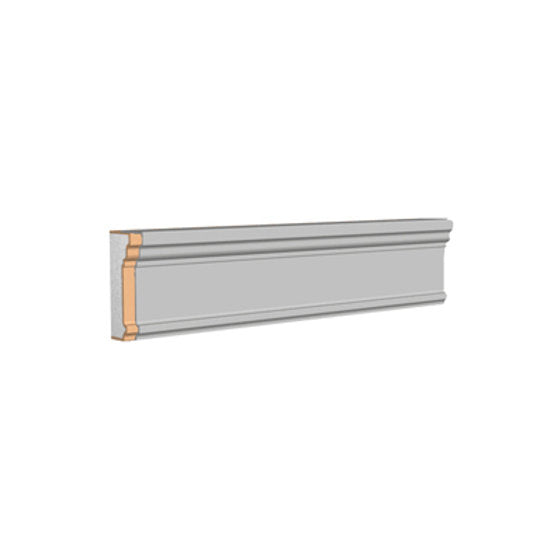

This isn’t just decoration. This is a statement. Our decorative trim moulding is an engineered system designed to elevate facades, create powerful first impressions, and endure for decades with zero maintenance. We transform high-density EPS foam into architectural masterpieces that are indistinguishable from their traditional counterparts, giving you complete creative control.

Every piece of our foam molding trim is a testament to precision:

- Exterior window & door surrounds: Frame your entryways and windows with elegance that commands attention.

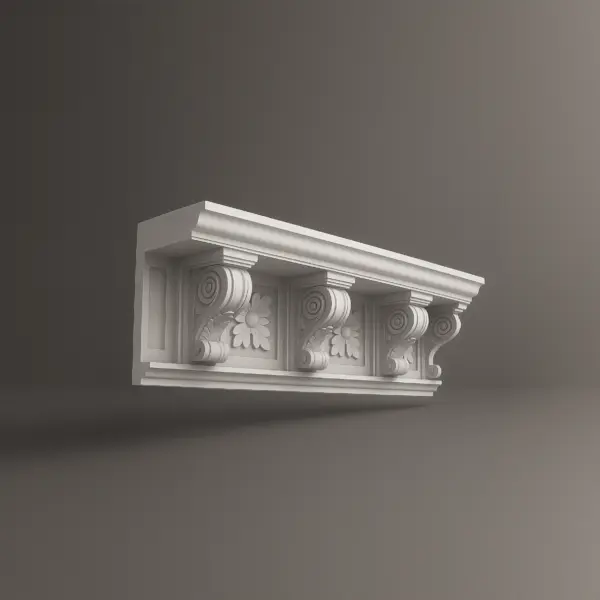

- Cornices & friezes: Add a touch of classical grandeur or sleek modern lines to your rooflines.

- Columns, capitals & bases: Achieve a majestic look without the need for structural reinforcement.

- Wall & quoin panels: Create texture, depth, and a sense of permanence on any exterior surface.

Get the high-end finish you designed, delivered ready for a fast, flawless installation.

The science behind flawless, feather-light architectural trim

The skepticism is understandable: “It’s foam.” But this is where engineering transforms a common material into an architectural game-changer. At the heart of every piece of stucco foam trim is a structural, high-density Expanded Polystyrene (EPS) core, precision-cut by CNC machines directly from your CAD files.

But the real magic is our proprietary polyurea hard coat. This isn’t paint; it’s armor. We encapsulate the foam core in a spray-applied elastomer that creates a seamless, waterproof, and brutally tough shell. This process turns a lightweight shape into a monolithic element with incredible impact resistance.

The final layer is an integrated, architectural-grade finish that provides the authentic texture of stucco or stone and is impervious to weathering, UV rays, and cracking. This is how our exterior foam trim molding delivers both the delicate details of your design and the rugged durability the real world demands.

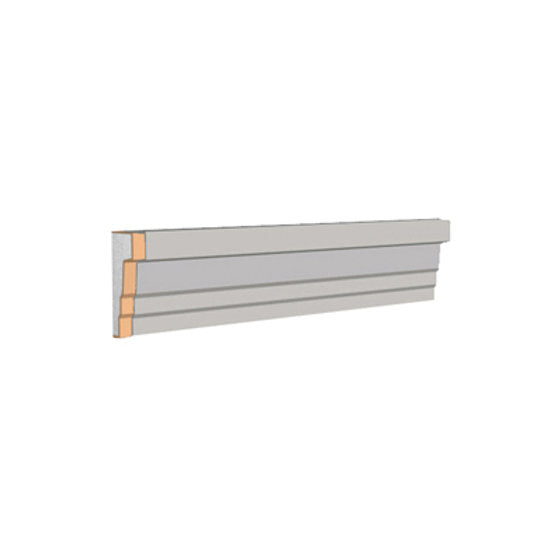

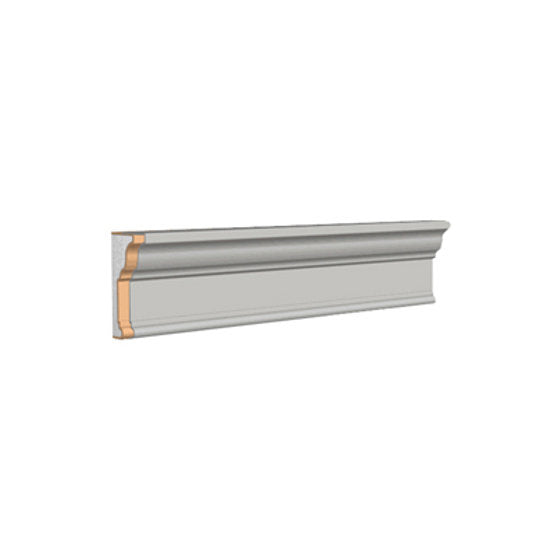

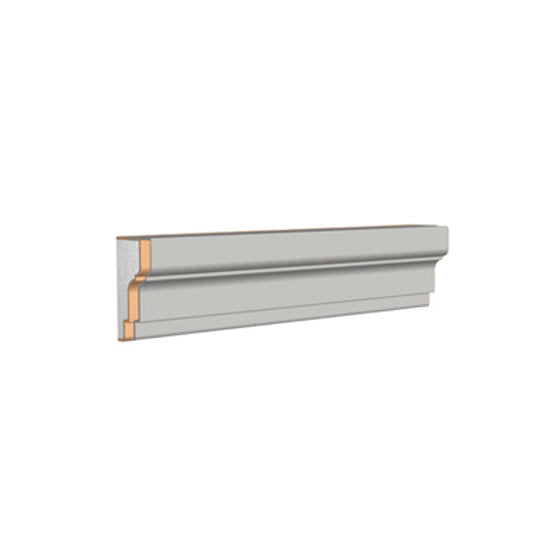

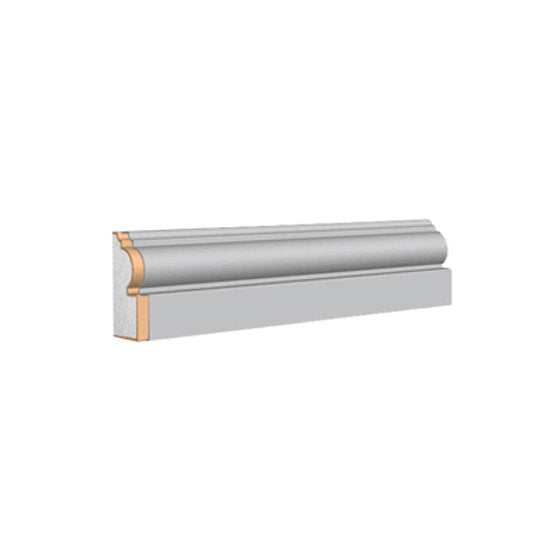

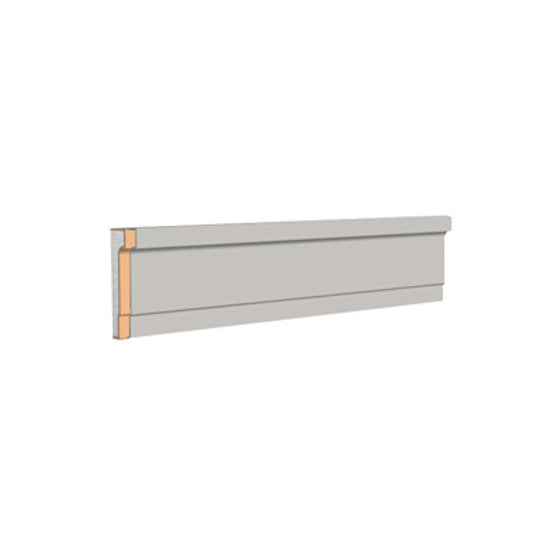

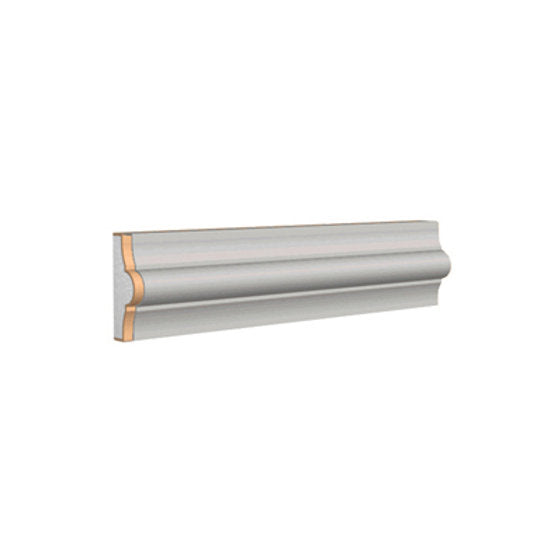

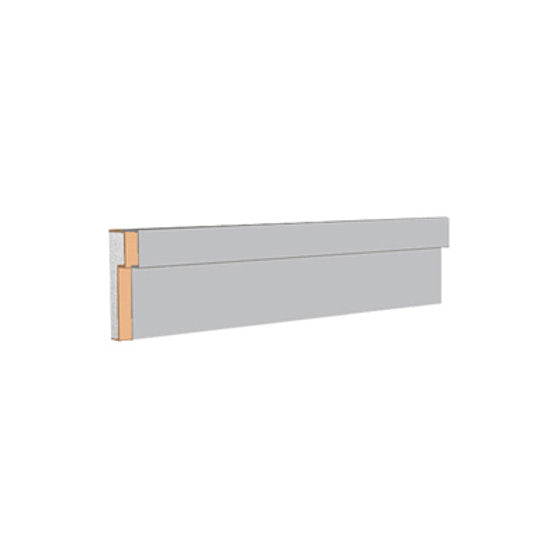

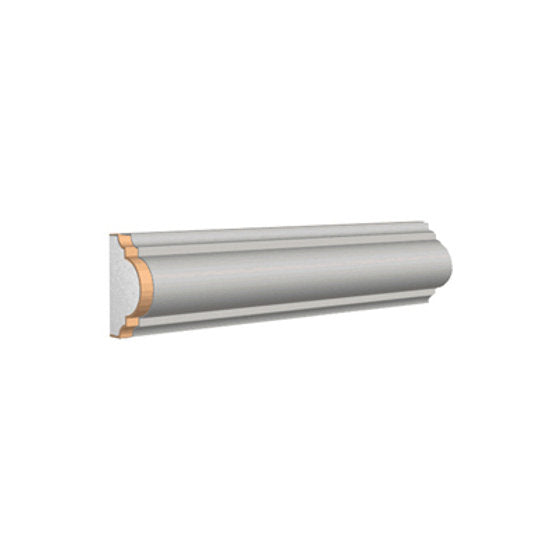

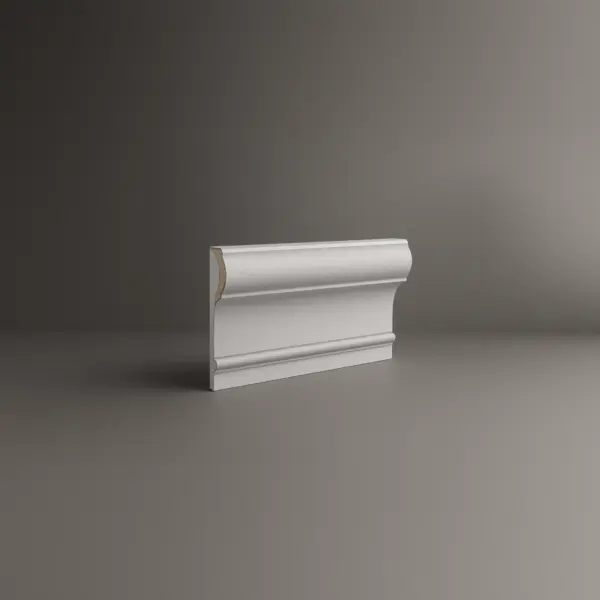

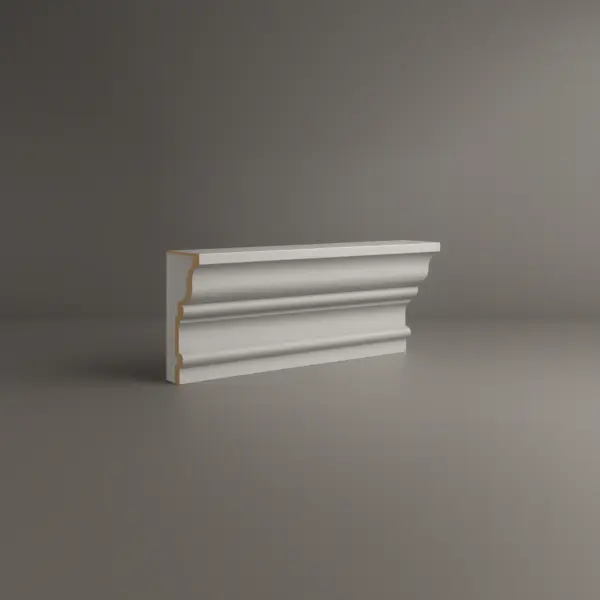

Assortment of decorative trims

Foam trim vs. traditional materials:

The unfair advantage

Choose a smarter, lighter, and more adaptable solution. Choose exterior stucco foam window trim that’s engineered for the 21st century.

Demands cranes, large crews, and structural reinforcement, inflating project costs and timelines.

Multi-week installation is slowed by masonry work, curing times, and weather delays.

Prone to cracking (concrete) and rot (wood), requiring constant and costly upkeep.

Designs are restricted by expensive molds or material constraints. Custom work is prohibitively expensive.

Inflated by expensive labor, heavy equipment, and recurring maintenance.

Eliminates the need for cranes or heavy machinery, slashing logistics costs and complexity.

Prefabricated elements are installed by a small crew in hours, not weeks, accelerating project completion.

Impervious to rot, insects, and cracking with an 80-100 year lifespan. Zero maintenance required.

CNC fabrication can produce any profile, from historic replication to complex modern designs, perfectly.

Significant savings on labor, equipment, and shipping, with zero long-term maintenance expenses.

Сustom exterior decorative trim

From your cad file to your job site in 4 simple steps

We’ve engineered our process to be as precise and efficient as our products.

It all begins with a deep dive into your project. We work as your technical partner to transform creative intent into a solid, actionable plan.

- Analyze Your Inputs: We review your architectural plans, CAD files, sketches, and inspirational images to understand your design from every angle.

- Define the Scope: In a collaborative consultation, we discuss the project’s aesthetic goals, site conditions, and technical requirements to ensure a perfect fit.

- Establish a Technical Blueprint: We finalize all specifications, from dimensions to finish textures, creating a clear roadmap for fabrication that aligns perfectly with your vision.

We bridge the gap between concept and cost, providing you with the clarity and confidence to move forward.

- Receive a Detailed 3D Visualization: We create and send you a precise 3D model, allowing you to see exactly how your custom architectural elements will look before production begins.

- Get a Transparent, Itemized Proposal: You receive a clear, comprehensive quote with no hidden fees. We believe in total transparency, so you know exactly what you’re investing in.

- Maintain Complete Control for Final Approval: We don’t proceed until you are 100% satisfied. You have the final say on the design and budget before we move to the next stage.

This is where your approved design becomes a physical reality, crafted with an obsessive focus on quality in our 45,000 sq. ft. workshop.

- Execute with Robotic Accuracy: Our state-of-the-art CNC hot-wire machines carve your architectural elements with flawless precision, matching your approved 3D models to the exact specification.

- Armor for a Century of Performance: Our skilled artisans apply our signature Polyurea hard coat, creating a seamless, impact-resistant, and weatherproof shell designed for decades of durability.

- Verify Through Rigorous Quality Control: Every single piece undergoes a multi-point inspection to ensure it meets our exact standards for shape, finish, and structural integrity.

Our commitment extends all the way to your job site, ensuring a smooth and successful installation.

- Protect with Secure, Custom Crating: We build specialized shipping crates for every project, guaranteeing your elements arrive in pristine, ready-to-install condition.

- Streamline Your Installation: Your pieces are delivered pre-assembled and lightweight, designed to slash on-site labor time and eliminate the need for heavy machinery.

- Support Your Crew to the Finish Line: We provide detailed installation guides and offer live Zoom support to answer your team’s questions, guaranteeing a perfect final fit.

It all begins with a deep dive into your project. We work as your technical partner to translate creative intent into a solid, actionable plan.

- Analyze Your Inputs: We review your architectural plans, CAD files, sketches, and inspirational images to understand your design from every angle.

- Define the Scope: In a collaborative consultation, we discuss the project’s aesthetic goals, site conditions, and technical requirements to ensure a perfect fit.

- Establish a Technical Blueprint: We finalize all specifications, from dimensions to finish textures, creating a clear roadmap for fabrication that aligns perfectly with your vision.

We bridge the gap between concept and cost, providing you with the clarity and confidence to move forward.

- Receive a Detailed 3D Visualization: We create and send you a precise 3D model, allowing you to see exactly how your custom architectural elements will look before production begins.

- Get a Transparent, Itemized Proposal: You receive a clear, comprehensive quote with no hidden fees. We believe in total transparency, so you know exactly what you’re investing in.

- Maintain Complete Control for Final Approval: We don’t proceed until you are 100% satisfied. You have the final say on the design and budget before we move to the next stage.

This is where your approved design becomes a physical reality, crafted with an obsessive focus on quality in our 45,000 sq. ft. workshop.

- Execute with Robotic Accuracy: Our state-of-the-art CNC hot-wire machines carve your decorative architectural shapes with flawless precision, matching your approved 3D model to the millimeter.

- Armor for a Century of Performance: Our skilled artisans apply our signature Polyurea hard coat, creating a seamless, impact-resistant, and weatherproof shell designed for decades of durability.

- Verify Through Rigorous Quality Control: Every single piece undergoes a multi-point inspection to ensure it meets our exacting standards for form, finish, and structural integrity.

Our commitment extends all the way to your job site, ensuring a smooth and successful installation.

- Protect with Secure, Custom Crating: We build custom shipping crates for your elements, ensuring they arrive on-site in pristine, ready-to-install condition.

- Streamline Your Installation: Your pieces are delivered pre-assembled and lightweight, designed to slash on-site labor time and eliminate the need for heavy machinery.

- Support Your Crew to the Finish Line: We provide detailed installation guides and offer live Zoom support to answer your team’s questions, guaranteeing a perfect final fit.

Our project gallery

Engineered for every architectural vision

From commercial developers to custom home architects, we provide a strategic advantage to the professionals who refuse to compromise.

Finally, a material that keeps up with your imagination. We fabricate custom interior architectural trim and exterior elements to your exact specifications, giving you the freedom to create iconic designs without the constraints of traditional materials.

Accelerate your timelines and improve your bottom line. The rapid installation of our lightweight decorative trim means faster project completion, reduced labor costs, and stunning curb appeal that attracts premium buyers and tenants.

Make your building a landmark. Our decorative wall trim is perfect for retail centers, hotels, and corporate campuses that need to project an image of quality and permanence, all with a solution that requires virtually no maintenance.

Deliver the custom details that high-end clients demand. From ornate decorative stucco foam trim to sleek, modern accents, our products provide the “wow” factor that sets luxury properties apart from the competition.

Before & after:

The transformative power of detail

Discover our workHow architectural trim elevates your property

Architectural trim is more than just a finishing touch—it’s the first and most powerful signal of a building’s quality. Before a client walks through your door, the details of your facade have already told them a story about your standards, your permanence, and your brand. Well-engineered architectural trim doesn’t just complete a building; it defines its value.

- A Language of Quality that Builds Instant TrustA sharp, substantial cornice or a perfectly executed set of decorative exterior window trim speaks a universal language of precision and investment. It demonstrates an uncompromising commitment to quality that builds immediate credibility with high-value tenants, clients, and partners. It says, "We don't cut corners," establishing a premium perception for your property.

- An Investment in Lasting Beauty, Not Perpetual MaintenanceWhile traditional wood trim rots and precast concrete cracks and stains, our exterior stucco foam trim is engineered to endure for a century with virtually zero upkeep. This isn't an expense; it's a smart, long-term asset. The low total cost of ownership protects your investment and frees up capital that would otherwise be spent on a frustrating cycle of repairs and repainting.

- Signature Style That Aligns with Your BrandYour building's facade is a three-dimensional extension of your brand identity. With limitless design flexibility, we can engineer signature decorative trim profiles that perfectly align with your company’s aesthetic—whether it's the timeless authority of classical molding or the forward-thinking innovation of sleek, modern lines. Make your architecture an unforgettable part of your brand story.

Client testimonials

From your first idea to the final installation — our process is clear, fast, and designed to make every detail simple.

FAQ

What makes exterior trim a smart choice for modern architecture?

Exterior foam trim adds definition and personality to contemporary façades without compromising efficiency. Our stucco foam trim and exterior architectural trim create clean lines, emphasize geometry, and bring a sense of craftsmanship that stands out in modern construction — all while remaining lightweight, durable, and easy to work with.

Is foam trim difficult to install?

Not at all. It’s lightweight and easy to handle. We provide complete technical documentation and labeling to make the process smooth and straightforward.

How long does stucco foam trim last?

Decades. Our materials resist cracking, fading, and weathering even in humid or coastal climates.

Can you match existing façade colors?

Yes, perfectly. We custom-match finishes and textures to integrate seamlessly with your project’s materials.

You might be wondering — if you’re not in Florida, how can we possibly deliver your stucco foam trim on time and in perfect condition?

That’s a fair question, and we hear it often. We’ve been shipping stucco foam trim and foam trim nationwide for years, so logistics is something we take seriously. Every order is custom-packed, prefabricated, labeled, and protected for long transit. Whether you’re in Texas, California, or New York, we’ll get your trim to you safely, on schedule, and ready to install — just as if it came from next door.

Can foam trim be used in high-humidity regions?

Definitely. foam stucco trim is ideal for coastal climates — it won’t absorb water, swell, or deform, unlike wood or plaster.

How does foam trim increase property value?

It enhances curb appeal, defines character, and gives even standard buildings a premium look — which directly translates to higher appraisal and resale value.

Can I combine different trim styles in one project?

Of course. We often mix exterior architectural trim with modern minimalist lines. Our engineers help ensure proportion and consistency.

Is maintenance required?

Minimal. Occasional cleaning with water is enough. The surface finish protects against dirt and UV damage.

We can’t approve anything without exact drawings. Can you really handle that level of precision?

We can — and we do it every day. Our engineering team prepares detailed 3D models, cross-sections, and accurate measurement layouts to make the approval process simple and transparent. You’ll see every curve and radius before production begins — no assumptions, no risks, just verified precision.

Before making a decision, can we see and test your material ourselves?

Of course. We provide texture samples so your team can evaluate the texture and coatingunder real conditions. We fully understand how important these details are — that’s why we want you to experience the quality of our foam trim long before it arrives at your project site.

Can foam trim be painted?

Yes. Although most of our products come pre-finished, they can be repainted with standard exterior or interior coatings if desired.

Do you deliver across the United States?

Yes, we deliver across continental United States.

& specification catalog

Get the definitive guide to our custom decorative architectural foam shapes. This free catalog is packed with hundreds of design profiles, detailed technical specifications, and real-world project applications.

Have a project in mind?

Our dedicated specialists are ready to collaborate with you, turning your concept into a detailed plan with a transparent budget. Let’s bring your vision to life!

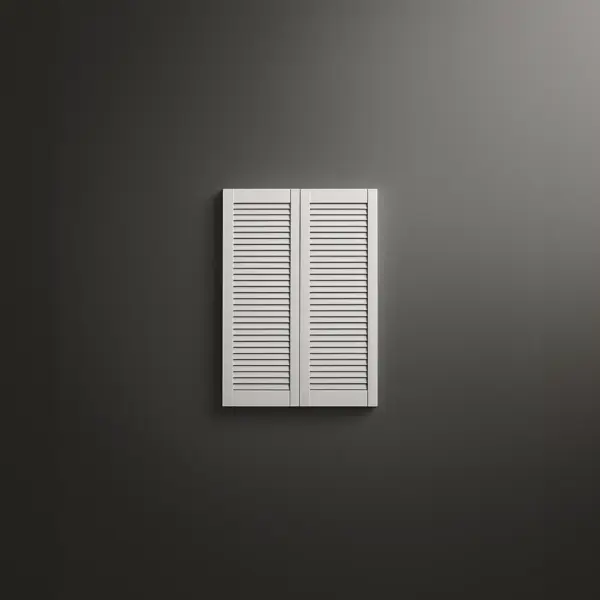

More architectural shapes

We provide architects, builders, and homeowners with turnkey decorative elements that transform any project — fast, easy, and cost-effective.

Decorative trims

For over 25 years, Decorative Architectural Shapes has been creating architectural details that give buildings their character. Some projects stand out not because they’re the biggest, but because every line, proportion, and element works together. That precision comes from thoughtful design, the kind that turns design concepts into distinctive, lasting architecture. Our decorative wall trim, decorative exterior window trim, architectural exterior trim, and hundreds of other solutions don’t just adorn buildings; they define their identity.

We know that in this industry, professionals look for more than just a product — they need a partner they can count on. Reliability means drawings that match reality, shipments that arrive when promised, and quality that holds up long after installation. That’s why we built our process around precision and trust — turning every design idea into durable, lightweight architectural details, engineered and made right here in the USA.

What is decorative trim and why it matters

Foam trim is the architectural language of detail. It outlines, emphasizes, and completes the composition of a building. Whether it’s an exterior decorative exterior house trim that frames windows and cornices, or an interior decorative wall trim defining a wall panel, each element plays a vital role in shaping visual coherence.

More than aesthetic appeal, window trim improves proportion and flow. It can visually extend height, balance asymmetry, or add rhythm to long façades. In interiors, it turns plain drywall into expressive architectural panels, introducing light, shadow, and sophistication.

Window trim performs both aesthetic and functional roles:

| Core Function | Technical and Architectural Impact |

|---|---|

| Architectural Definition | Visually separates zones and highlights openings to enhance depth. Decorative wall trim or foam molding trim transforms blank walls into dynamic architectural surfaces. |

| Protection and Sealing | Covers expansion joints and protects corners from moisture infiltration, ensuring the long-term integrity of surface finishes. |

| Design Unification | When applied across different parts of a building, trim elements bring unity, making modern structures feel cohesive and thoughtfully designed. |

| Historical Restoration | For heritage façades, lightweight stucco foam trim allows us to recreate the refined ornamentation of stone or plaster without putting extra weight on aging walls. A few years ago in Savannah, we restored a century-old municipal building — the original limestone details were crumbling, but our foam replicas matched them perfectly in texture and scale, keeping the architecture authentic and structurally sound. |

| Cost Efficiency | Since foam trim is light and easy to handle, it significantly cuts installation time and reduces the need for heavy machinery or large crews. Contractors often tell us the savings are felt not only in labor but also in logistics — smaller teams, faster work, fewer adjustments on-site, and ultimately, a smoother project timeline. |

These are not minor details — they’re the fingerprints of quality design. Over decades, we’ve seen how a simple architectural trim line can completely transform the perception of a building.

Materials and manufacturing technology

Modern architecture deserves materials that not only perform flawlessly but also inspire confidence. At Decorative Architectural Shapes, we craft our stucco foam trim with the same care a sculptor gives to marble — shaping lightweight, enduring elements that rival the strength and elegance of stone yet move as easily as air.

Each piece begins with high-density EPS foam — a material engineered for precision and resilience. Its internal structure acts like a honeycomb, giving it strength without weight. It won’t absorb moisture, it won’t warp in the heat, and it refuses to crack under pressure. The outer protective coating forms a durable shell that locks in color and texture, even under relentless Florida sun or coastal humidity.

This is where technology meets artistry: CNC precision cutting defines every curve, while our finishing process brings surfaces to life — smooth, tactile, and ready to face decades of weather. The result is a material that looks like carved stone but installs with the ease of wood, proving that beauty and practicality can, in fact, coexist.

Our process combines precision engineering with artistry. Using CNC machinery, we cut every profile — whether a foam trim molding, stucco foam window trim, or architectural molding & trim — to exact specifications. Every product is inspected for geometry, density, and coating consistency.

Advantages of foam-based trim systems

- Lightweight – Up to ten times lighter than plaster or concrete, reducing load on walls and simplifying logistics.

- Durability – Reinforced coating prevents damage from impact and weather exposure.

- Versatility – From smooth modern profiles to intricate classical ornaments, all achievable with foam trim molding.

- Cost-effectiveness – Less time, less labor, no need for cranes or special lifting equipment.

- Eco-friendly – Made from recyclable materials, non-toxic, compliant with U.S. environmental standards.

No need to worry that installation will turn into chaos — we’ve made sure everything goes smoothly and predictably. Our technical documentation isn’t the kind you need a magnifying glass to decipher: it’s clear, concise, and free of unnecessary “architectural poetry.” Your team will find everything they need to work confidently and stay on schedule. And to save time on site, we pre-connect some of the elements right at the factory — so when the shipment arrives, it all comes together like a well-made puzzle, without the stress or guesswork.

When architects visit our factory, they’re often surprised at how lightweight an eight-foot foam stucco trim piece can be. You can easily lift it with one hand — it’s that light, almost weightless. But once the coating is applied, the material completely transforms: it takes on the look of natural stone or wood, and only a specialist could tell the difference. That’s what makes it unique — the precision of engineering meets a refined sense of form and design, turning a practical solution into a piece of architectural art.

Where and how our solutions are used

Window trim can enhance nearly any architectural concept — from minimalist to baroque, from new construction to restoration. Our clients across the U.S. use it to add value, elegance, and precision to both interiors and exteriors.

Residential architecture

For homes, villas, and townhouses, decorative exterior window trim and decorative exterior house trim, roof overhangs are the most common choices. They outline windows, smooth the junctions between materials, and give the roofline that final, confident touch that ties everything together. One homeowner in Miami told us after the project, “Now my house finally feels like it belongs here — bright, coastal, alive.” The team finished weeks ahead of schedule because the foam trim was so light they didn’t need heavy scaffolding or complicated lifting gear.

Commercial and corporate buildings

In commercial projects, exterior architectural trim brings order and balance to the façade. It highlights structure, adds rhythm, and gives the building a clean, professional look that feels intentional from every angle. For a corporate complex in Tampa, we designed linear exterior foam trim molding that unified several wings of glass façades into a cohesive composition.

Leisure architecture and hospitality spaces

Hotels, resorts, and entertainment venues rely on personality and atmosphere. Decorative wall trim and foam window trim help create memorable environments without excessive weight or maintenance. We’ve worked with boutique hotels in Orlando where architectural molding & trim became the signature element of the entire brand aesthetic.

Historical restoration

Historic buildings require materials that preserve authenticity but reduce structural strain. Exterior stucco foam trim is ideal here — it replicates stone profiles, remains lightweight, and can be custom-matched to existing textures. In Savannah, our team reproduced 19th-century cornices for a heritage property using foam stucco trim technology, keeping the look genuine while cutting installation time in half.

Interior design

Inside, decorative wall trim transform plain rooms into refined, dimensional spaces. Designers often use them for accent walls, hallways, and meeting rooms.

Comparison with alternative materials

Traditional materials like plaster, wood, or stone each have their strengths — but also limitations. Foam-based systems bridge the gap between aesthetics and performance.

| Material | Weight | Moisture Resistance | Installation Ease | Cost |

|---|---|---|---|---|

| Plaster | Heavy | Low | Complex | High |

| Stone | Very heavy | High | Requires machinery | Very high |

| Wood | Medium | Moderate | Needs maintenance | Medium |

| Architectural foam (Foam trim / stucco foam trim) | Light | High | Simple, no heavy machinery | Optimal |

In Orlando, a construction firm switched from cast stone to our foam stucco trim for a mid-rise project. The result? Half the labor hours, zero cracks after two years, and a façade that still looks brand new.

Why working with Decorative Architectural Shapes makes sense

At Decorative Architectural Shapes, we see ourselves not just as manufacturers but as partners in design execution. We know that in architecture, predictability equals trust — and trust builds long-term collaboration.

Why our partners choose Decorative Architectural Shapes:

- Experience that matters – over 25 years in architectural manufacturing.

- Made in the USA – full control over production, quality, and timing.

- Customization – Every project is different and we like it that way. Whether it’s a classic cornice or a one-of-a-kind modern profile, we shape each piece to your specs.

- Precision – CNC cut and verified down to fractions of an inch.

- Ready to install – Labeled, preconnected and organized for your team’s convenience.

- Lightweight – Strong, stable and easy to handle.

- Reliable delivery – Clear timelines, regular updates, on-time nationwide shipping.

For a recent Tampa headquarters, we produced over 300 linear feet of architectural molding & trim in less than a month. Every element fit perfectly — no cutting, no adjustments. “This is how manufacturing should work,” the project manager told us.

& specification catalog

Get the definitive guide to our custom decorative architectural foam shapes. This free catalog is packed with hundreds of design profiles, detailed technical specifications, and real-world project applications.

Have a project in mind?

Our dedicated specialists are ready to collaborate with you, turning your concept into a detailed plan with a transparent budget. Let’s bring your vision to life!