Architectural corbels: beyond mere decoration

We deliver the monumental aesthetic of traditional corbels in a precisely engineered, impossibly lightweight system.

The anatomy of an indestructible architectural detail

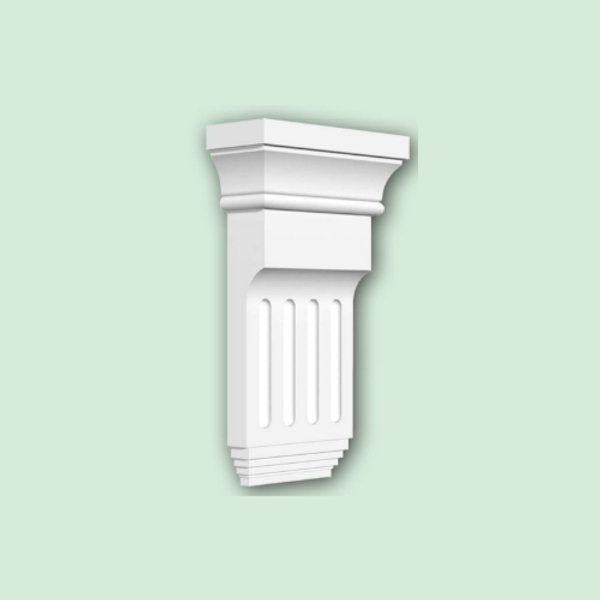

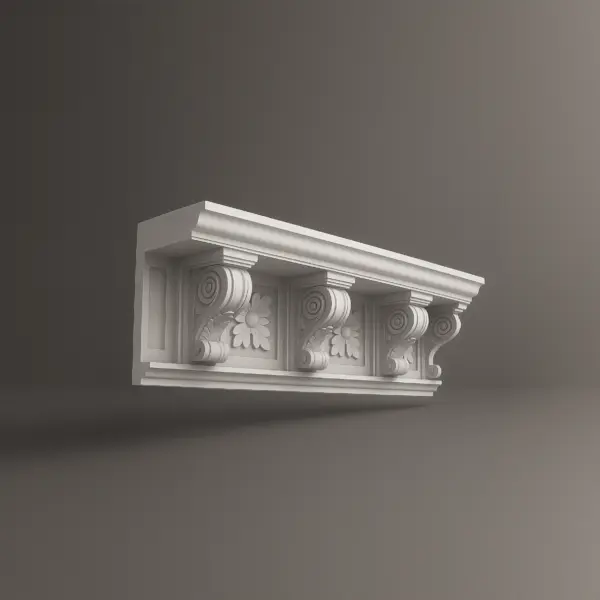

Elegant, powerful, and built for a century. Our architectural corbels exterior are crafted from a high-density, lightweight composite core to replicate the solid, hand-carved look of traditional materials without the engineering nightmares. Perfect for rooflines, eaves, balconies, and entryways, these elements add a statement of quality and architectural integrity that lasts.

Each exterior corbel is an engineered system:

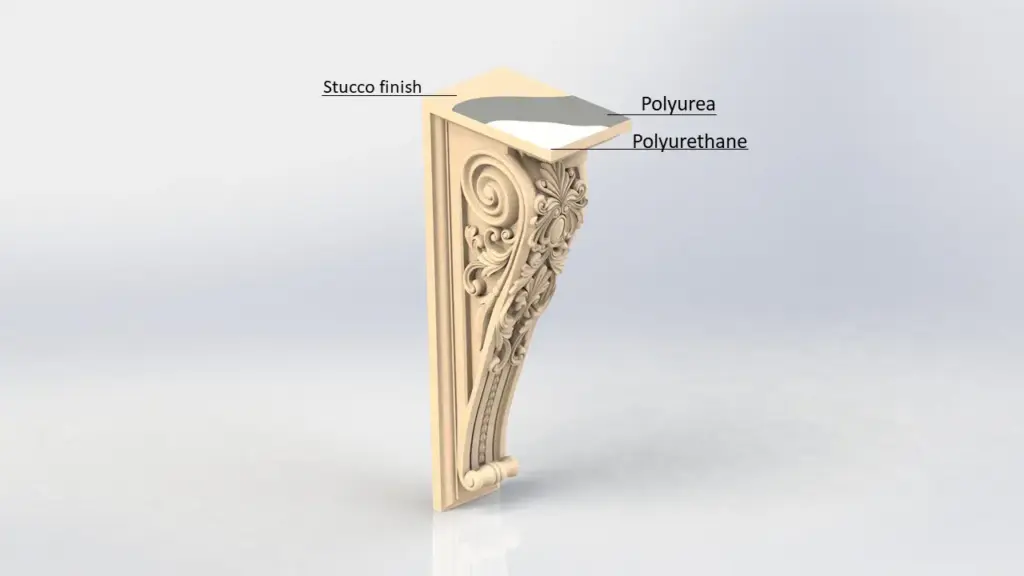

- Structural EPS Core: A high-density Expanded Polystyrene core, precision-cut with CNC technology to your exact specifications.

- Polyurea Armor: Our signature polyurea hard coat encapsulates the core, creating a waterproof, impact-proof shell.

- Architectural Finish: A robust, integrated finish that provides the authentic texture of painted wood or stone and is 100% ready for installation upon arrival.

Get a system that adds character with precision.

The science behind a 100-year corbel

Our architectural brackets and corbels are built from an advanced composite of materials engineered for extreme longevity and flawless aesthetics. At the heart is a structural, high-density Expanded Polystyrene (EPS) foam, shaped with robotic precision to ensure perfect geometry for every single piece.

This core is then encapsulated in our proprietary polyurea hard coat. Think of it as armor. This spray-applied elastomer creates a seamless, waterproof, and impact-resistant shield, transforming the lightweight foam into a monolithic element with incredible strength and resilience.

The final layer is an integrated, architectural-grade finish that provides the authentic texture you demand and superior resistance to weathering, UV rays, and cracking. This advanced construction makes our decorative exterior corbels robust, elegant, and virtually maintenance-free for life.

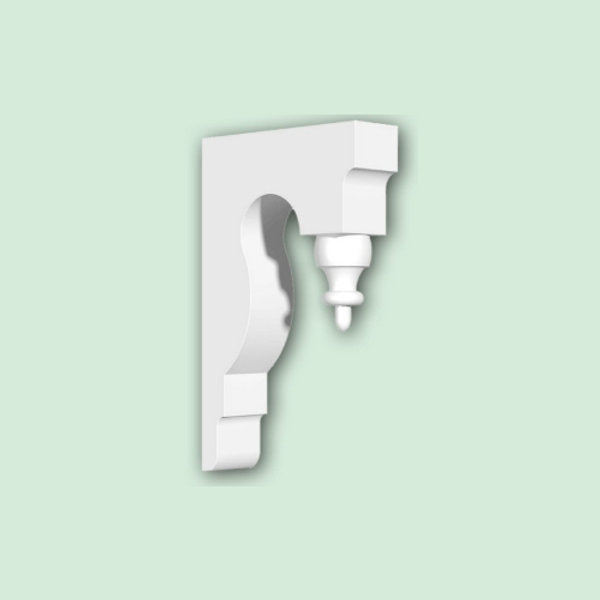

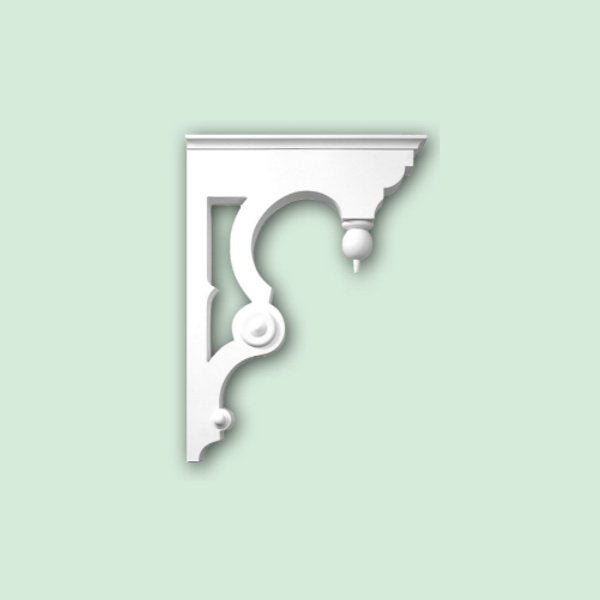

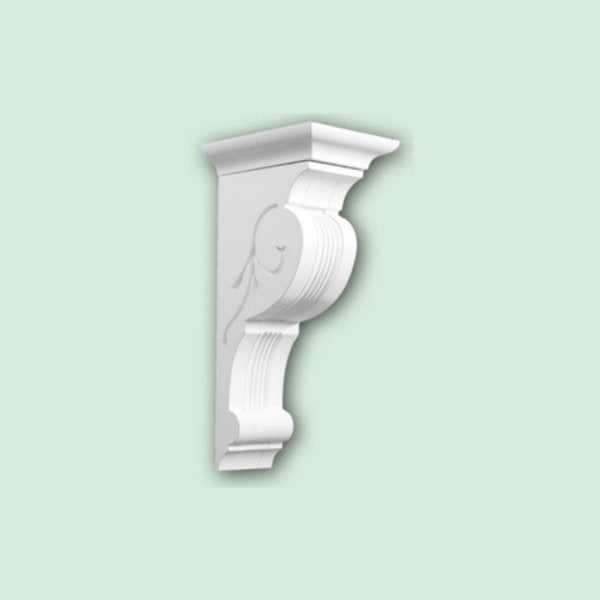

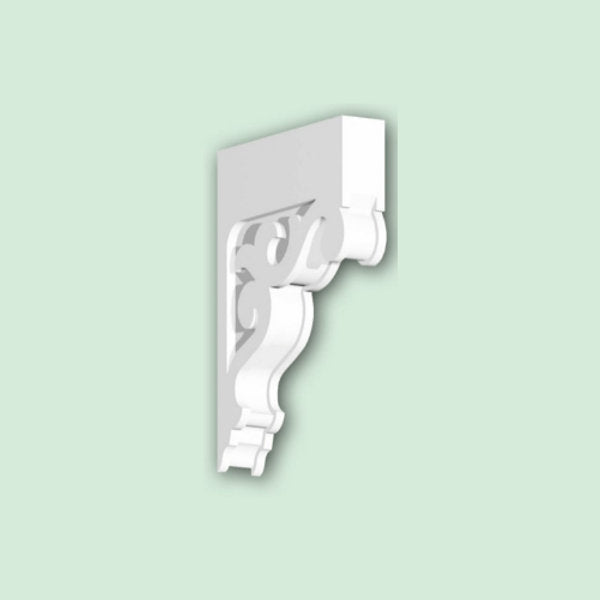

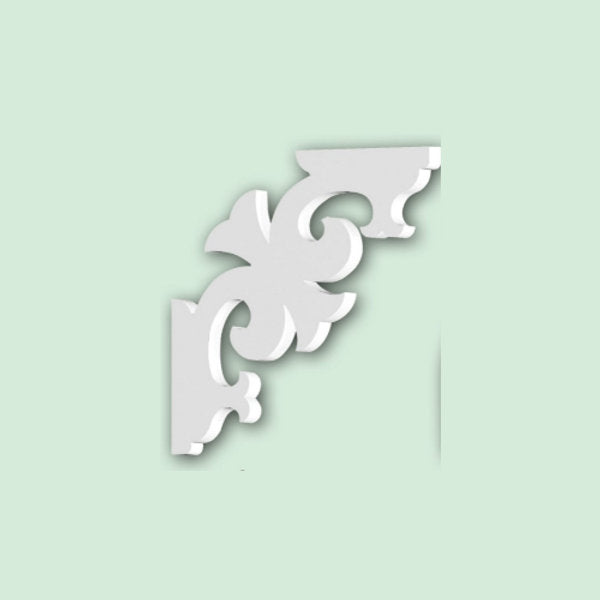

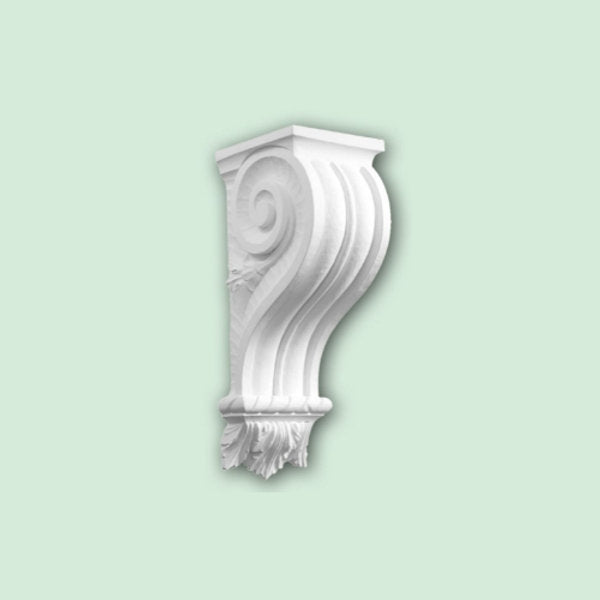

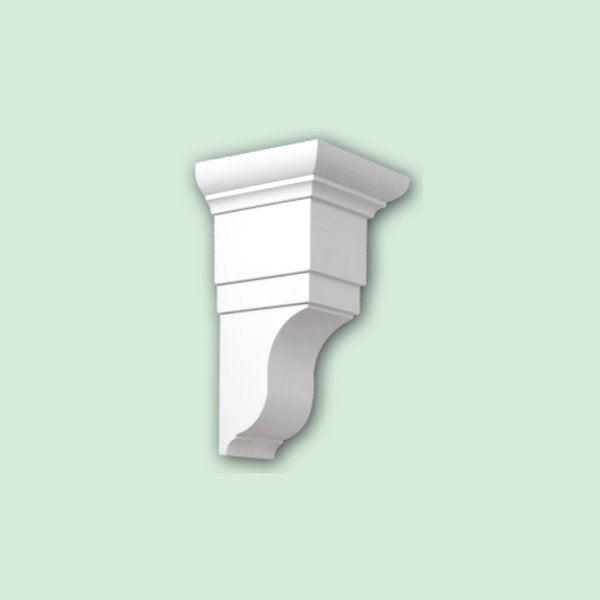

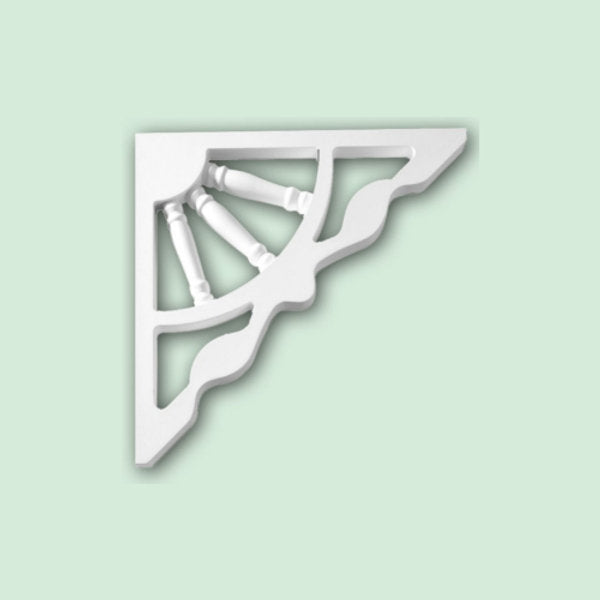

Assortment of custom exterior corbels & brackets

Engineered corbels vs. traditional wood & stone:

the clear advantage

Stop fighting heavy, high-maintenance materials. Choose lightweight, durable, and fully custom exterior corbels on house designs—built to last, made in the USA.

Requires cranes, large crews, and reinforced mounting, creating a logistical nightmare on site.

Slow on-site work requires skilled labor and is prone to weather delays, killing your schedule.

Vulnerable to rot, pests, and weather damage. Demands continuous maintenance like painting and sealing.

Custom shapes are incredibly costly and time-consuming to carve, limiting your creative options.

High material and labor costs are followed by years of expensive maintenance and repairs.

Up to 90% lighter. No cranes or structural reinforcement needed. Drastically reduces shipping and labor costs.

Arrives pre-finished and ready to mount. Installs in hours, not weeks, accelerating your project timeline.

Impervious to rot, insects, and cracking. A true "set it and forget it" solution that never needs painting.

If you can draw it, we can build it—any size, any complexity. Your exact vision, delivered.

Lower upfront costs for labor and equipment, plus zero lifetime maintenance expenses.

Сustom exterior corbels & brackets

How to order architectural corbels & brackets

From your initial sketch to job site delivery—our process is transparent, fast, and engineered for your success.

It all begins with a deep dive into your project. We work as your technical partner to transform creative intent into a solid, actionable plan.

- Analyze Your Inputs: We review your architectural plans, CAD files, sketches, and inspirational images to understand your design from every angle.

- Define the Scope: In a collaborative consultation, we discuss the project’s aesthetic goals, site conditions, and technical requirements to ensure a perfect fit.

- Establish a Technical Blueprint: We finalize all specifications, from dimensions to finish textures, creating a clear roadmap for fabrication that aligns perfectly with your vision.

We bridge the gap between concept and cost, providing you with the clarity and confidence to move forward.

- Receive a Detailed 3D Visualization: We create and send you a precise 3D model, allowing you to see exactly how your custom architectural elements will look before production begins.

- Get a Transparent, Itemized Proposal: You receive a clear, comprehensive quote with no hidden fees. We believe in total transparency, so you know exactly what you’re investing in.

- Maintain Complete Control for Final Approval: We don’t proceed until you are 100% satisfied. You have the final say on the design and budget before we move to the next stage.

This is where your approved design becomes a physical reality, crafted with an obsessive focus on quality in our 45,000 sq. ft. workshop.

- Execute with Robotic Accuracy: Our state-of-the-art CNC hot-wire machines carve your architectural elements with flawless precision, matching your approved 3D models to the exact specification.

- Armor for a Century of Performance: Our skilled artisans apply our signature Polyurea hard coat, creating a seamless, impact-resistant, and weatherproof shell designed for decades of durability.

- Verify Through Rigorous Quality Control: Every single piece undergoes a multi-point inspection to ensure it meets our exact standards for shape, finish, and structural integrity.

Our commitment extends all the way to your job site, ensuring a smooth and successful installation.

- Protect with Secure, Custom Crating: We build specialized shipping crates for every project, guaranteeing your elements arrive in pristine, ready-to-install condition.

- Streamline Your Installation: Your pieces are delivered pre-assembled and lightweight, designed to slash on-site labor time and eliminate the need for heavy machinery.

- Support Your Crew to the Finish Line: We provide detailed installation guides and offer live Zoom support to answer your team’s questions, guaranteeing a perfect final fit.

It all begins with a deep dive into your project. We work as your technical partner to translate creative intent into a solid, actionable plan.

- Analyze Your Inputs: We review your architectural plans, CAD files, sketches, and inspirational images to understand your design from every angle.

- Define the Scope: In a collaborative consultation, we discuss the project’s aesthetic goals, site conditions, and technical requirements to ensure a perfect fit.

- Establish a Technical Blueprint: We finalize all specifications, from dimensions to finish textures, creating a clear roadmap for fabrication that aligns perfectly with your vision.

We bridge the gap between concept and cost, providing you with the clarity and confidence to move forward.

- Receive a Detailed 3D Visualization: We create and send you a precise 3D model, allowing you to see exactly how your custom architectural elements will look before production begins.

- Get a Transparent, Itemized Proposal: You receive a clear, comprehensive quote with no hidden fees. We believe in total transparency, so you know exactly what you’re investing in.

- Maintain Complete Control for Final Approval: We don’t proceed until you are 100% satisfied. You have the final say on the design and budget before we move to the next stage.

This is where your approved design becomes a physical reality, crafted with an obsessive focus on quality in our 45,000 sq. ft. workshop.

- Execute with Robotic Accuracy: Our state-of-the-art CNC hot-wire machines carve your decorative architectural shapes with flawless precision, matching your approved 3D model to the millimeter.

- Armor for a Century of Performance: Our skilled artisans apply our signature Polyurea hard coat, creating a seamless, impact-resistant, and weatherproof shell designed for decades of durability.

- Verify Through Rigorous Quality Control: Every single piece undergoes a multi-point inspection to ensure it meets our exacting standards for form, finish, and structural integrity.

Our commitment extends all the way to your job site, ensuring a smooth and successful installation.

- Protect with Secure, Custom Crating: We build custom shipping crates for your elements, ensuring they arrive on-site in pristine, ready-to-install condition.

- Streamline Your Installation: Your pieces are delivered pre-assembled and lightweight, designed to slash on-site labor time and eliminate the need for heavy machinery.

- Support Your Crew to the Finish Line: We provide detailed installation guides and offer live Zoom support to answer your team’s questions, guaranteeing a perfect final fit.

Our project gallery

Engineered solutions for

every architectural style

Whether you’re the architect chasing a vision or the developer chasing a deadline, we deliver the details that define success.

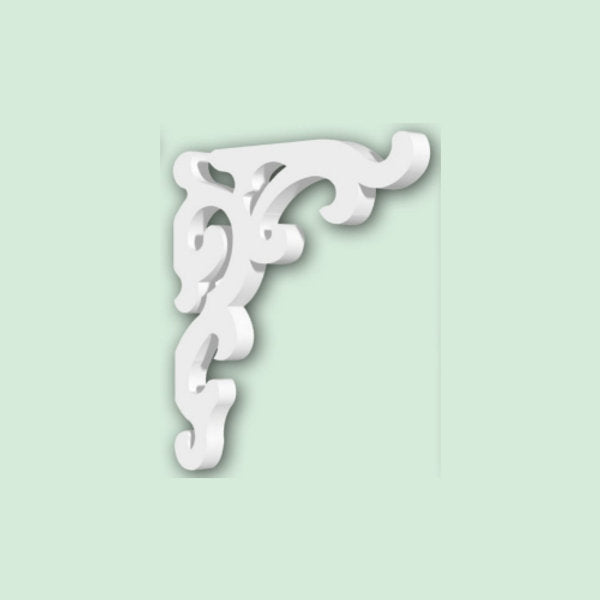

Finally, you can design those dramatic extra large exterior corbels or sleek modern exterior corbels without the structural engineer saying ‘no’. We fabricate to your exact CAD files, giving you the freedom to create iconic details without compromise.

Add high-value curb appeal that sells properties faster. Our lightweight exterior house corbels install in a fraction of the time of wood, saving you thousands in labor and keeping your projects on schedule and on budget.

Elevate your building’s facade with sophisticated decorative exterior brackets and corbels that communicate quality and permanence. Ideal for banks, hotels, and luxury retail centers that require a premium look with zero maintenance.

Replicate intricate victorian corbels exterior with perfect historical accuracy but with modern, long-lasting materials. Our process captures the finest details while ensuring the new elements won’t damage the existing structure.

Before and after:

From plain facade to architectural statement

Discover our workHow our corbels elevate your architectural integrity

An exterior corbel isn’t just a support; it’s a statement. It’s the detail that separates a standard building from a work of architecture. Well-engineered corbels communicate a commitment to quality, design, and permanence, elevating a property’s value and appeal from the moment it’s seen.

- Add Authentic Architectural CharacterA solid, well-proportioned corbel adds visual weight and historical context. It demonstrates an investment in detail that builds trust and signals a high-quality build to clients, buyers, and tenants.

- Boost Curb Appeal & Property ValueDecorative exterior corbels are one of the highest-ROI details you can add to a facade. They break up flat surfaces, create beautiful shadow lines, and give a building a memorable, custom-designed feel that stands out in any market.

- Design with Maintenance-Free ConfidenceUnlike wood that rots or stone that cracks, our engineered corbels are built to endure for decades with zero upkeep. This low total cost of ownership is a smart, long-term investment for any property, ensuring it looks as good in 20 years as it does on day one.

Client testimonials

From your first idea to the final installation — our process is clear, fast, and designed to make every detail simple.

FAQ

Can you manufacture extra large exterior brackets for deep overhangs?

Absolutely. Our extra large exterior brackets can be engineered with reinforced cores and load-bearing inserts. In Fort Myers, we supplied 5-feet-long brackets for a large veranda — installed in just two days.

Do you offer custom designs, or only exterior corbels for sale from a catalog?

Custom design is our specialty. We create unique profiles, textures, and finishes based on your project’s requirements.

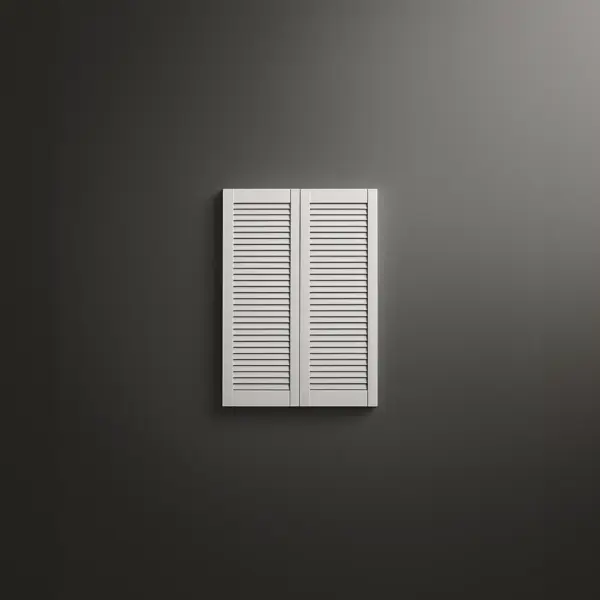

How do I choose the right exterior gable corbels for my roofline?

We evaluate slope, rafter spacing, and architectural style. Wood-textured versions suit farmhouse designs, while minimal profiles pair with modern architecture.

Will corbels on house exterior work with light-frame construction?

Yes. Our detailed documentation ensures safe and easy installation on any substrate.

Are outdoor decorative corbels suitable for coastal environments?

Yes. Our coatings resist salt spray and UV exposure. In Miami, they’ve retained their color and integrity for over three years.

What’s the typical installation process — how to install decorative corbels — for a contractor?

We provide a step-by-step guide for quick and easy installation. Installation is straightforward and does not require heavy equipment.

Can modern exterior corbels be combined with more traditional design elements?

Yes. They often serve as striking contrasts and are frequently used in mixed-style architecture.

Do decorative decorative corbels require maintenance?

Minimal maintenance is required — seasonal rinsing and occasional visual inspections are sufficient.

Can exterior brackets and corbels be matched in style and color?

Yes. We use Sherwin Williams color codes to create a unified design language across different components.

& specification catalog

Get the definitive guide to our custom decorative architectural foam shapes. This free catalog is packed with hundreds of design profiles, detailed technical specifications, and real-world project applications.

Have a project in mind?

Our dedicated specialists are ready to collaborate with you, turning your concept into a detailed plan with a transparent budget. Let’s bring your vision to life!

More architectural shapes

We provide architects, builders, and homeowners with turnkey decorative elements that transform any project — fast, easy, and cost-effective.

Exterior corbels & brackets

In commercial construction and architectural design, every project is a balance between deadlines, budgets, and visual expectations. Developers want predictable lead times. Architects need precision. Contractors look for solutions that are easy to install, scalable, and cost-effective. And everyone — from engineering firms to design studios — is searching for ways to make buildings look more expensive than they cost to build. This is where decorative corbels and exterior brackets and corbels step in: they are not just decorative elements but strategic architectural tools that enhance aesthetics, speed up installation, reduce total cost of ownership, and help projects stand out in a competitive market.

For over 25 years, we’ve been designing and manufacturing decorative corbels and brackets in the USA, working closely with architects, developers, and contractors on projects of all scales — from single-family residences and boutique hotels to large commercial developments and educational campuses. Our goal is simple: deliver engineered, precise, and visually compelling solutions that align perfectly with your design intent, meet your schedule, and optimize your costs.

Why exterior corbels are more than “just decoration”

At their core, exterior corbels are decorative elements projecting from a wall to support — or appear to support — overhangs, soffits, roofs, balconies, or gables. But in real-world construction, they do much more:

- Define architectural rhythm and give the façade depth.

- Create strong light and shadow contrasts that add perceived value.

- Bridge aesthetic and structural elements to unify the building’s composition.

- Protect soffits and roof overhangs when using exterior soffit corbels or exterior roof corbels.

On a recent university campus project in Georgia, for example, we designed custom exterior architectural corbels to visually lighten large roof overhangs while integrating concealed LED lighting. The result? A façade that looked high-end and cohesive — and a faster installation process thanks to our lightweight materials and pre-marked mounting points.

From concept to precision: materials and engineering that make a difference

Advanced materials built for real-world performance

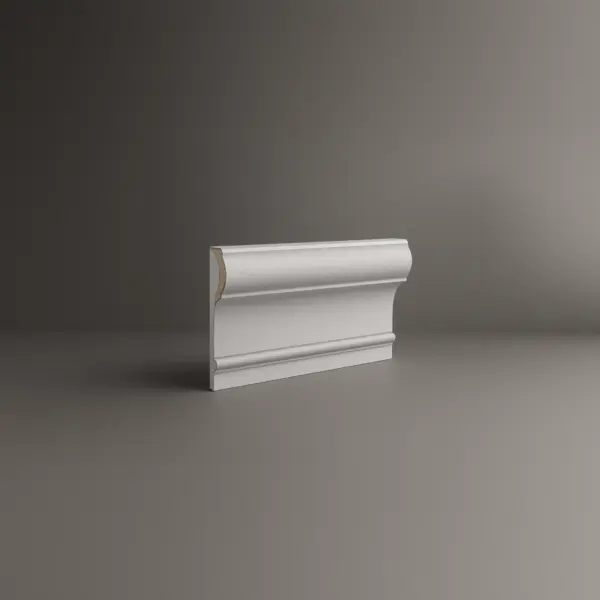

Our exterior corbels are built from high-density architectural foam with a multi-layer protective coating — a solution that combines the strength and stability needed for exterior use with minimal weight. Unlike stone, wood, or concrete, foam-based corbels are not affected by humidity, salt air, or temperature fluctuations. That’s why they’re ideal for hot, humid climates like Florida and coastal regions, where durability and long-term performance are non-negotiable.

Key benefits of our material technology:

- Lightweight, fast installation: 5–7 times lighter than stone or concrete — no cranes or heavy equipment needed.

- Clean, dry installation: No dust, no cutting stone on-site, no wet trades.

- Unlimited design freedom: From exterior victorian corbels with intricate carving to clean-lined modern decorative corbels.

- Hyper-realistic textures: Wood, stone, or metal textures that are visually indistinguishable from the real thing.

- Long-term durability: Moisture-resistant, UV-stable, and crack-proof

Expert production process — where engineering meets craftsmanship

Every project starts with a digital model. From there, we engineer the product to your specifications:

- 3D design & modeling: Our team develops precise CAD models.

- CNC shaping: High-precision milling ensures dimensional accuracy within millimeters.

- Layered reinforcement: Composite coatings add structural strength and weather resistance.

- Finishing & texturing: Custom finishes are applied, including color matching to existing façade materials.

- Quality control: Rigorous tests for coating adhesion, UV resistance, water absorption, and dimensional stability.

- Documentation: Every piece ships with technical drawings and installation instructions.

Logistics, documentation, and delivery: engineered to make your life easier

When deadlines are tight and coordination between trades is complex, logistics can make or break a project. That’s why we treat delivery not as a last-mile service but as part of the engineering process itself. Because all our exterior brackets and corbels are manufactured in the USA, we don’t just organize the shipping of the boxes — we orchestrate the flow of components so they arrive when and how your site needs them.

Every piece is packed with the care of a precision instrument. Our corbels and brackets are prefabricated and lightweight, and can be installed by simply gluing them to the wall – so your crew spends hours, not days, on-site. It’s a difference you feel immediately — less scaffolding time, less coordination stress, and a cleaner, faster build.

A good example comes from a large residential complex we supplied in Jacksonville. The developer was facing a tight six-week window before tenant move-ins, and delays from another supplier had already eaten into the schedule. We restructured production into phased shipments, delivering exterior corbels in the order they were needed — roofline components first, then soffit units, then decorative brackets. Because some of the assemblies were pre-mounted on carrier frames, installation time dropped by nearly 40%. What could have been a costly delay turned into an early handover — and a very happy client.

Documentation is treated with the same level of precision. Each delivery includes complete technical packages — detailed drawings, recommended adhesive specs, and even step-by-step installation checklists. The goal is simple: your installers shouldn’t have to guess, adjust, or improvise. Everything they need to do their job quickly and correctly is right there, from the first bracket to the final finish.

Built for what’s next: why our corbels set a new benchmark in architecture

Our decorative exterior corbels and decorative exterior brackets are not just components — they’re part of a new generation of building technology:

- Lightweight design means easier and faster installation.

- No heavy machinery, no construction dust, no site disruptions.

- Accurate manufacturing means no “on-site adjustments”.

- Realistic textures and finishes deliver premium aesthetics without the weight or maintenance.

On a restaurant project in Sarasota, switching from precast stone to our large exterior corbels cut installation time by 60%, eliminated crane rental costs, and allowed the grand opening to happen three weeks ahead of schedule — a significant ROI for the developer.

Styles and applications: how different corbel types transform architecture

From classical charm to contemporary minimalism

| Style | Description and Case Study |

|---|---|

| Victorian exterior corbels | Ornate, carved details ideal for restorations and heritage projects. We used them on a historic church restoration in St. Augustine, where the façade regained its original 19th-century character — now with modern durability against Florida’s humidity and sun. |

| Craftsman exterior corbels | Honest proportions and wood-grain textures. These were key to blending stone and stucco on a residential complex in Tampa, creating a unified, premium aesthetic. |

| Farmhouse exterior corbels | Clean lines with a rustic twist. At a ranch outside Orlando, this style preserved the “old farm” look while delivering modern performance. |

| Modern exterior corbels | Minimalist, geometric designs ideal for contemporary architecture. In an Atlanta tech campus project, they visually “supported” deep overhangs while keeping the design light and sharp. |

Functionality that goes beyond appearance

- Exterior soffit corbels and exterior roof corbels define eave lines and protect overhangs.

- Exterior gable corbels accentuate roof geometry and anchor the building’s profile.

- Exterior corner brackets are placed under cantilevered canopies.

In a coastal Miami development, our outdoor exterior corbels maintained their color and finish after three years of salt-air exposure — a proof point for investors planning additional waterfront projects.

Installation and maintenance: designed for contractor efficiency

We don’t perform installations ourselves — and that’s intentional. Our focus is on making the process so straightforward that your installation team can complete it quickly and correctly. Every shipment includes mounting diagrams, hardware recommendations, and technical documents.

Typical installation flow:

- Components arrive pre-marked and ready to install.

- Adhesive specifications are clearly documented.

- Lightweight materials eliminate the need for cranes or specialized labor.

- Our engineering team remains available for installation support if needed.

We also offer logistics assistance, including carefully planned transport and — for Florida and Georgia projects — partial pre-assembly for even faster installation and better visual results. We can also incorporate brackets and corbels into cornice, creating a prefabricated solution that saves even more time on the jobsite.

Maintenance is virtually zero: seasonal rinsing and a simple visual inspection. Our coatings maintain their finish and integrity for years, even under harsh sun and humidity.

Where exterior corbels deliver maximum value

Our architectural brackets and corbels, as well as window boxes are used across a wide range of applications:

- Residential developments and townhomes, where visual appeal boosts property value.

- Commercial and hospitality projects like hotels, restaurants, and retail spaces that rely on curb appeal.

- Educational campuses and museums, where design language must balance performance and prestige.

- Religious buildings and civic structures that demand historical authenticity and long-term durability.

- Custom private residences seeking unique architectural identity.

In a Georgia university campus project, we supplied over 200 exterior architectural brackets — all installed in just one week without cranes or field modifications. This accelerated the build schedule and eliminated costly delays.

Why working with Decorative Architectural Shapes is a strategic advantage

- Made in USA: Local production means predictable schedules and quality control.

- Custom engineering: We design to your specs or collaborate from concept to final product.

- Logistics support: On-time deliveries, partial assembly options, and full documentation.

- Technical partnership: We’re more than a supplier — we’re part of your project team.

- Proven experience: 25+ years of expertise across residential, commercial, and institutional sectors.

Our approach is not just about selling a product. It’s about providing a solution that delivers value across the entire project lifecycle — from design and budgeting to installation and long-term performance.

Exterior corbels and brackets are more than architectural accessories. They are strategic tools that elevate design, accelerate schedules, reduce costs, and help projects achieve a premium look without premium challenges. We provide engineered, precision-built, and visually compelling solutions — from decorative exterior brackets and rafter tails to custom brackets — all tailored to your needs, from the first sketch to final installation.

Contact us today to discuss your project. Request a quote, order a sample, or send us your drawings — and let’s build something remarkable together.

& specification catalog

Get the definitive guide to our custom decorative architectural foam shapes. This free catalog is packed with hundreds of design profiles, detailed technical specifications, and real-world project applications.

Have a project in mind?

Our dedicated specialists are ready to collaborate with you, turning your concept into a detailed plan with a transparent budget. Let’s bring your vision to life!