What are architectural sills & bands?

These aren’t just trim pieces; they’re the details that define your design.

The details that define the entire design

Elegant, functional, and essential for high-end design, our architectural sills and bands are the finishing elements that create a polished, cohesive look. They add visual weight and sophisticated detail to window and door surrounds, break up monotonous wall surfaces, and establish a powerful design language across the entire building envelope.

Each element is crafted for a specific architectural purpose:

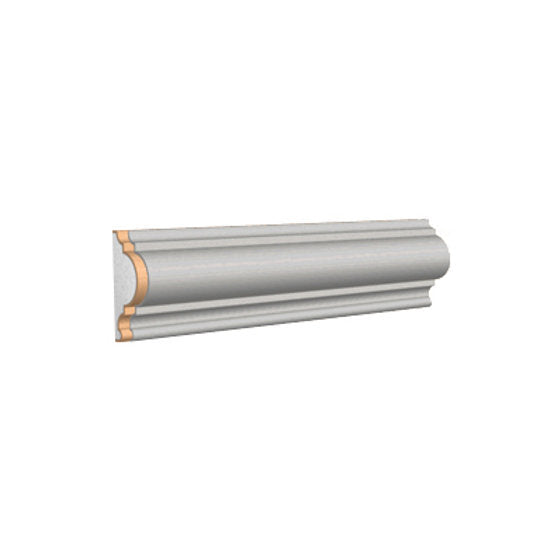

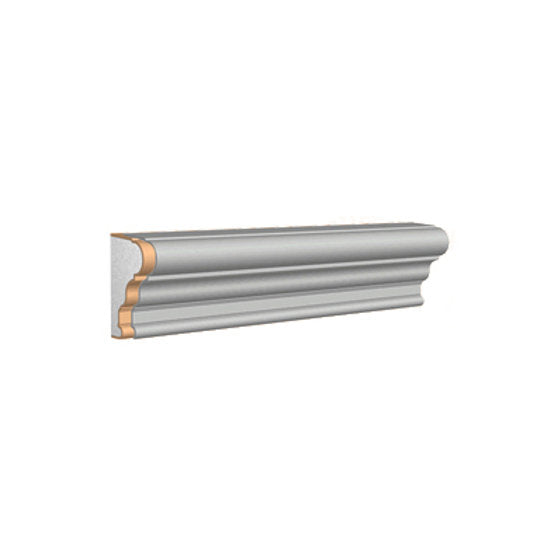

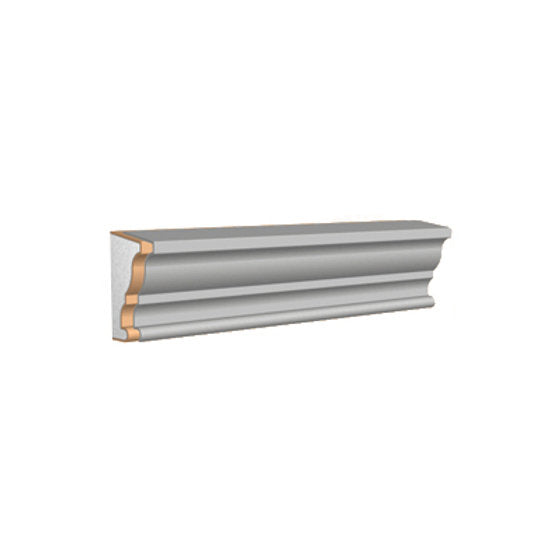

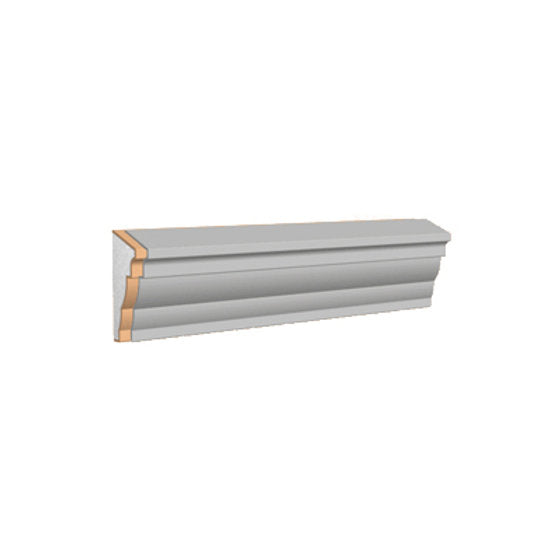

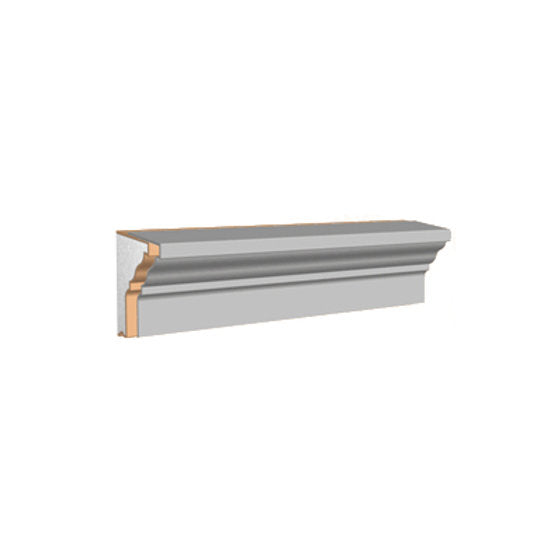

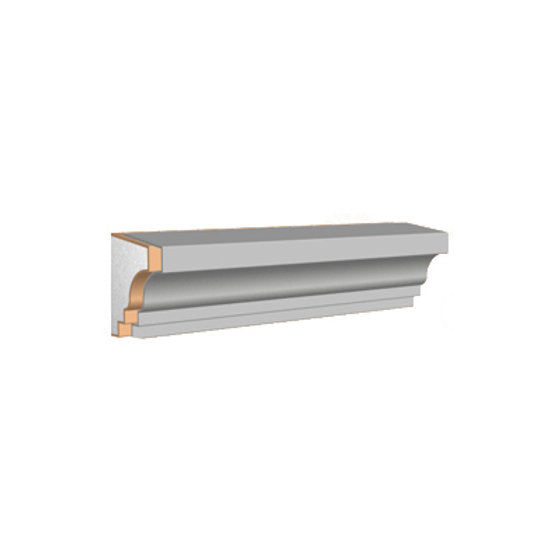

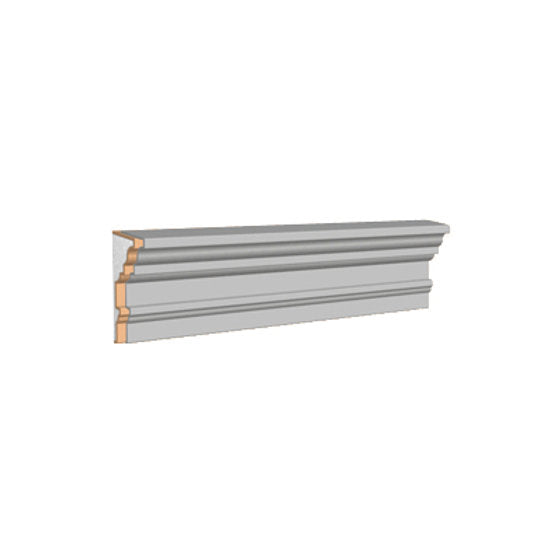

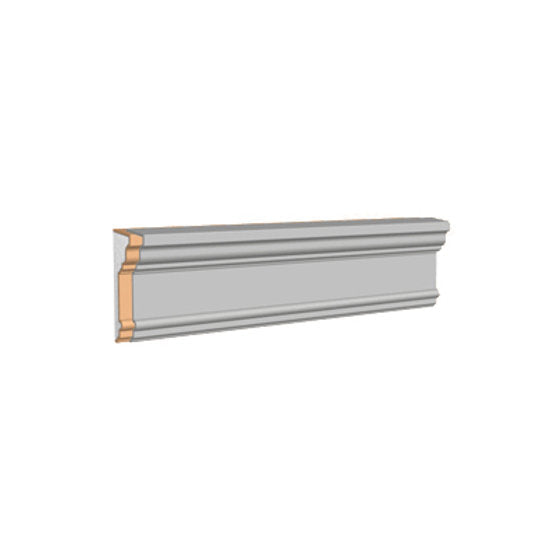

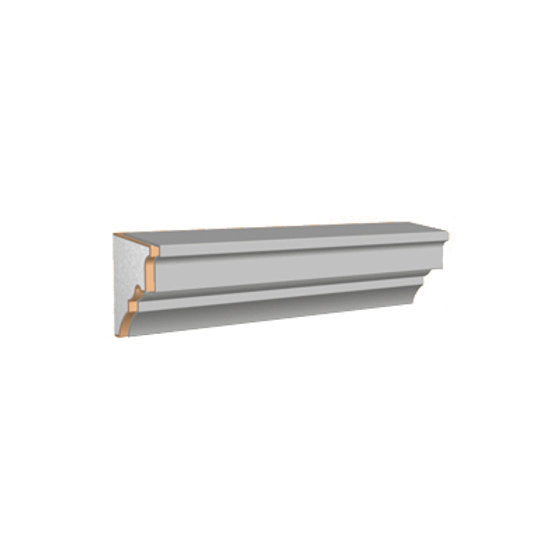

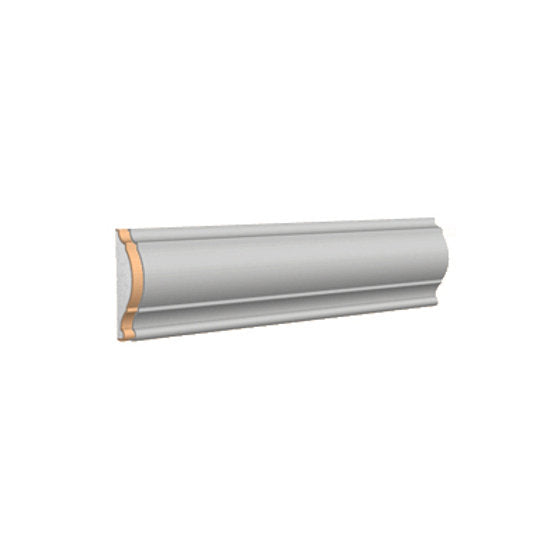

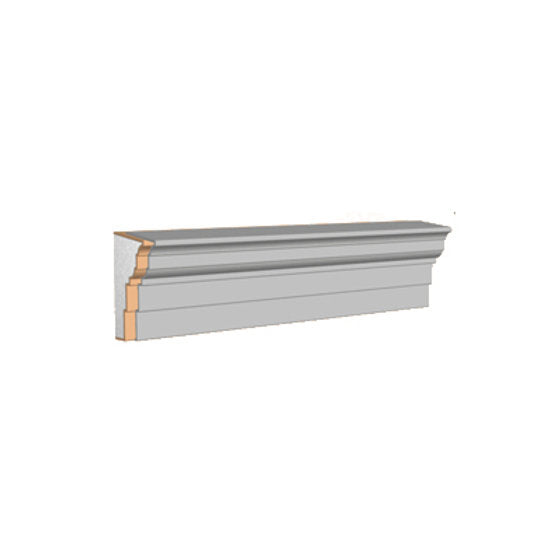

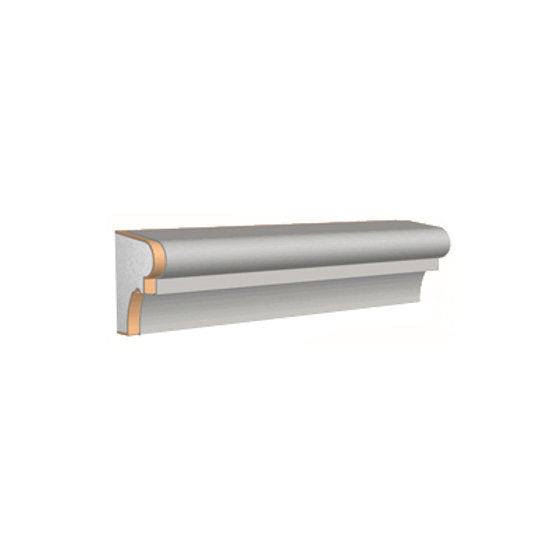

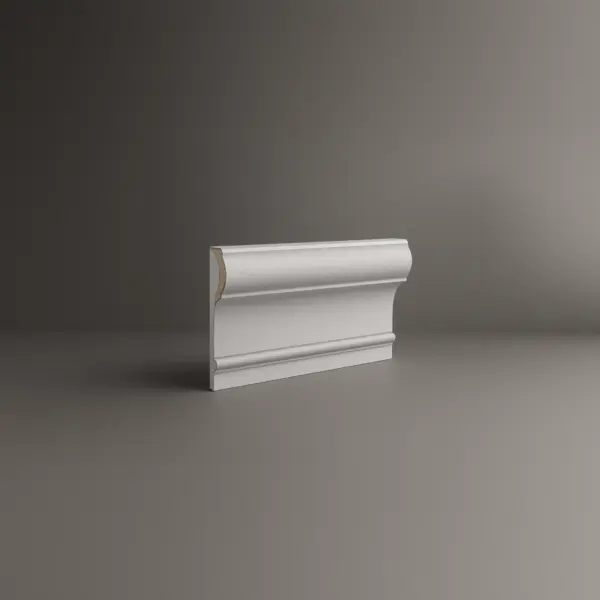

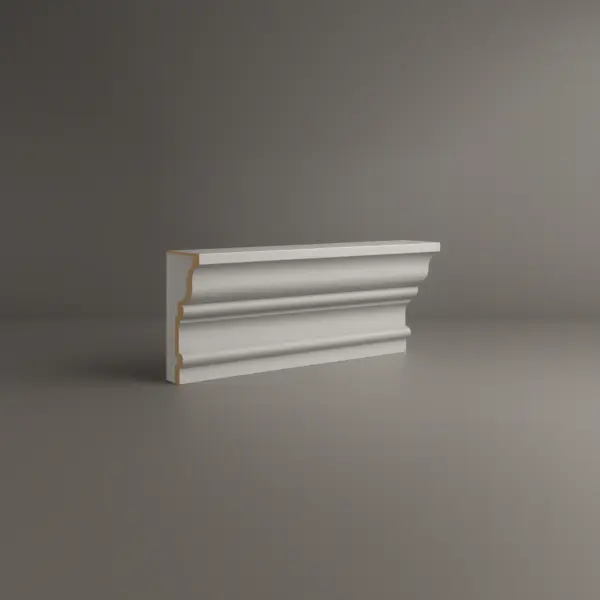

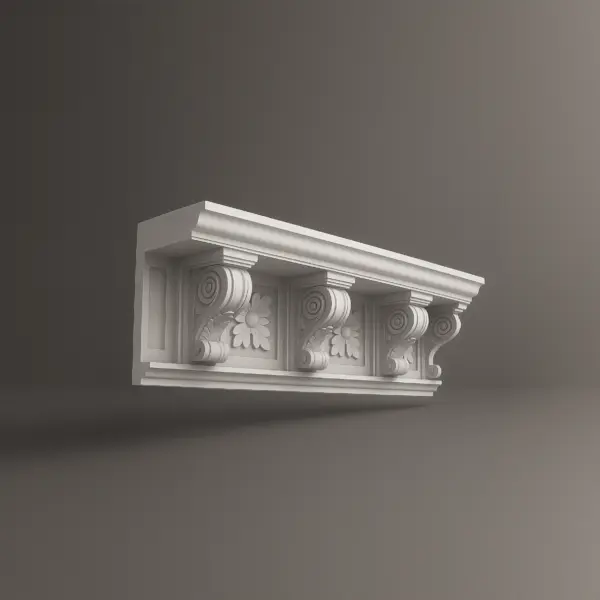

- Decorative Window Sills: The foundational element beneath a window or opening. Our decorative window sills provide a crisp, supportive ledge that channels water away and creates a strong horizontal anchor for the design.

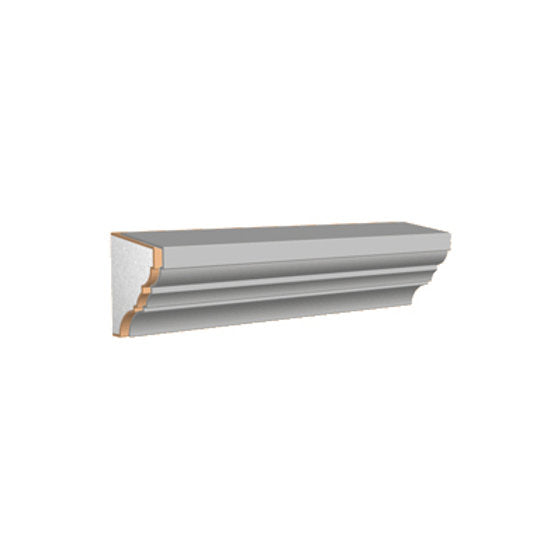

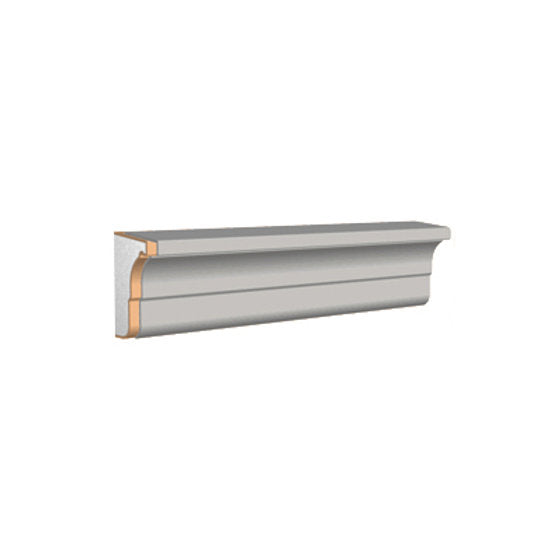

- Architectural Bands: Continuous horizontal profiles that wrap the building. Also known as bandings or belt lines, they create visual separation between floors, cap wall sections, or add a dynamic linear feature to the facade.

Get the precision-molded profiles that bring your elevations to life.

Engineered for precision. Coated for immortality

Our architectural elements are born from a fusion of advanced material science and precision engineering. The process starts with a solid block of high-density Expanded Polystyrene (EPS) foam, which is CNC-machined to your exact profile specifications. This gives us a geometrically perfect, yet incredibly lightweight, core.

That core is then encapsulated in our signature polyurea hard coat. This isn’t just a layer of paint; it’s a spray-applied elastomer that cures in seconds to form a seamless, waterproof, and impact-resistant shell. This “armor” transforms the foam into a monolithic structure with unbelievable strength, ready to withstand decades of weather, moisture, and UV exposure.

The final surface is a textured, architectural finish that provides the authentic look of masonry and a perfect canvas for any color you specify.

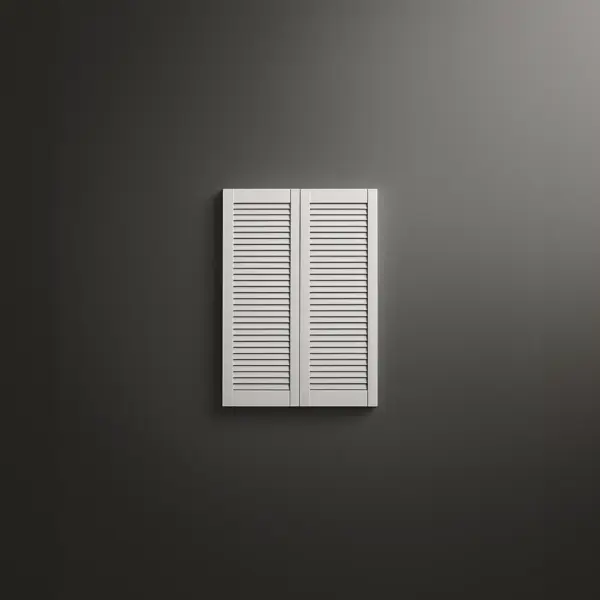

Assortment of sills & bands

Engineered foam vs. precast concrete:

The unfair advantage

Stop wrestling with heavy, brittle, and unforgiving materials. There’s a smarter way to build. Choose lightweight, durable, and fully customizable architectural elements—built to last, made in the USA.

Requires cranes, reinforced structures, and large crews, driving up costs and timelines.

Requires specialized crews and is vulnerable to costly weather delays.

Prone to cracking, water damage, and staining. Requires ongoing, costly maintenance.

Custom designs are extremely costly with very long lead times.

Expensive labor, machinery rentals, and structural needs inflate the budget.

90% lighter. No cranes or structural reinforcement needed. Slash shipping costs and jobsite complexity.

A small crew with standard tools gets it done, accelerating your timeline.

Waterproof polyurea shell won't crack, chip, or rot. Zero maintenance for an 80-100 year lifespan.

If you can draw it, our CNC technology can create it—from modern profiles to historic replicas.

Save big on labor, equipment, shipping, and engineering. A smarter investment.

Сustom sills & bands

How to order your architectural sills & bands

From your initial CAD file to job site delivery—our process is transparent, fast, and engineered for your success.

It all begins with a deep dive into your project. We work as your technical partner to transform creative intent into a solid, actionable plan.

- Analyze Your Inputs: We review your architectural plans, CAD files, sketches, and inspirational images to understand your design from every angle.

- Define the Scope: In a collaborative consultation, we discuss the project’s aesthetic goals, site conditions, and technical requirements to ensure a perfect fit.

- Establish a Technical Blueprint: We finalize all specifications, from dimensions to finish textures, creating a clear roadmap for fabrication that aligns perfectly with your vision.

We bridge the gap between concept and cost, providing you with the clarity and confidence to move forward.

- Receive a Detailed 3D Visualization: We create and send you a precise 3D model, allowing you to see exactly how your custom architectural elements will look before production begins.

- Get a Transparent, Itemized Proposal: You receive a clear, comprehensive quote with no hidden fees. We believe in total transparency, so you know exactly what you’re investing in.

- Maintain Complete Control for Final Approval: We don’t proceed until you are 100% satisfied. You have the final say on the design and budget before we move to the next stage.

This is where your approved design becomes a physical reality, crafted with an obsessive focus on quality in our 45,000 sq. ft. workshop.

- Execute with Robotic Accuracy: Our state-of-the-art CNC hot-wire machines carve your architectural elements with flawless precision, matching your approved 3D models to the exact specification.

- Armor for a Century of Performance: Our skilled artisans apply our signature Polyurea hard coat, creating a seamless, impact-resistant, and weatherproof shell designed for decades of durability.

- Verify Through Rigorous Quality Control: Every single piece undergoes a multi-point inspection to ensure it meets our exact standards for shape, finish, and structural integrity.

Our commitment extends all the way to your job site, ensuring a smooth and successful installation.

- Protect with Secure, Custom Crating: We build specialized shipping crates for every project, guaranteeing your elements arrive in pristine, ready-to-install condition.

- Streamline Your Installation: Your pieces are delivered pre-assembled and lightweight, designed to slash on-site labor time and eliminate the need for heavy machinery.

- Support Your Crew to the Finish Line: We provide detailed installation guides and offer live Zoom support to answer your team’s questions, guaranteeing a perfect final fit.

It all begins with a deep dive into your project. We work as your technical partner to translate creative intent into a solid, actionable plan.

- Analyze Your Inputs: We review your architectural plans, CAD files, sketches, and inspirational images to understand your design from every angle.

- Define the Scope: In a collaborative consultation, we discuss the project’s aesthetic goals, site conditions, and technical requirements to ensure a perfect fit.

- Establish a Technical Blueprint: We finalize all specifications, from dimensions to finish textures, creating a clear roadmap for fabrication that aligns perfectly with your vision.

We bridge the gap between concept and cost, providing you with the clarity and confidence to move forward.

- Receive a Detailed 3D Visualization: We create and send you a precise 3D model, allowing you to see exactly how your custom architectural elements will look before production begins.

- Get a Transparent, Itemized Proposal: You receive a clear, comprehensive quote with no hidden fees. We believe in total transparency, so you know exactly what you’re investing in.

- Maintain Complete Control for Final Approval: We don’t proceed until you are 100% satisfied. You have the final say on the design and budget before we move to the next stage.

This is where your approved design becomes a physical reality, crafted with an obsessive focus on quality in our 45,000 sq. ft. workshop.

- Execute with Robotic Accuracy: Our state-of-the-art CNC hot-wire machines carve your decorative architectural shapes with flawless precision, matching your approved 3D model to the millimeter.

- Armor for a Century of Performance: Our skilled artisans apply our signature Polyurea hard coat, creating a seamless, impact-resistant, and weatherproof shell designed for decades of durability.

- Verify Through Rigorous Quality Control: Every single piece undergoes a multi-point inspection to ensure it meets our exacting standards for form, finish, and structural integrity.

Our commitment extends all the way to your job site, ensuring a smooth and successful installation.

- Protect with Secure, Custom Crating: We build custom shipping crates for your elements, ensuring they arrive on-site in pristine, ready-to-install condition.

- Streamline Your Installation: Your pieces are delivered pre-assembled and lightweight, designed to slash on-site labor time and eliminate the need for heavy machinery.

- Support Your Crew to the Finish Line: We provide detailed installation guides and offer live Zoom support to answer your team’s questions, guaranteeing a perfect final fit.

Our project gallery

The perfect profile for every project

From architectural vision to market-ready property, our elements deliver value at every stage.

Finally achieve the clean, monolithic look you’ve envisioned. Specify intricate modern window sills or sweeping, continuous bands without worrying about weight or structural limitations. We provide the technical partnership to bring your most ambitious elevations to life.

Increase curb appeal and accelerate project timelines. Our lightweight elements install in a fraction of the time of concrete, getting your properties market-ready faster. It’s the most cost-effective way to create a high-end look that sells.

Make your building a landmark. From corporate headquarters to retail centers and hotels, our custom sills and bands create a powerful, sophisticated brand identity that communicates quality and permanence from the first glance.

Add timeless elegance to your home’s exterior or create unique interior features. Our products are perfect for everything from classic exterior decorative window sills to sleek, modern interior window sills that add a custom touch to your living space.

From flat to fantastic:

A facade transformation

Discover our workMore than trim

It's a statement

Architectural elements are the language of your building. They tell a story of quality, intention, and attention to detail.

- Create Visual Hierarchy & ControlSills and bands are not just decoration; they are tools for guiding the eye. They establish rhythm, create deliberate focal points, and give a sense of order and stability to the entire structure, making the design feel intentional and complete.

- Signal Quality and Perceived ValueJust like a tailored suit, crisp architectural details signal a higher standard. A building with well-defined lines and thoughtful accents is perceived as more valuable, more permanent, and better constructed, attracting premium tenants and buyers.

- Build a Cohesive Brand IdentityYour building's facade is your brand's first handshake. Whether you need the sleek, minimalist profile of modern window sills for a tech campus or a classic, robust look for a financial institution, our custom capabilities ensure your architecture is a perfect extension of your brand.

Client testimonials

From your first idea to the final installation — our process is clear, fast, and designed to make every detail simple.

FAQ

We’re restoring a 1920s courthouse. Can you match the original stone sills so they don’t look out of place?

We get this question a lot — and the answer is a confident yes. Foam isn’t a compromise on aesthetics. We can recreate virtually any historical profile and texture, from weathered sandstone to hand-chiseled granite. One of my favorite projects was a courthouse restoration in Macon, Georgia. The original limestone sills were crumbling and unsafe, but the city didn’t want to lose the building’s character. We scanned the old profiles, reproduced them in foam, and applied a mineral-based coating that mimicked aged stone so convincingly that local preservationists couldn’t tell the difference. It’s one of those moments that still makes us proud.

How fast can you actually deliver? We’ve had suppliers promise four weeks and then delay us for months?

We understand — schedule reliability is everything. Because we manufacture in the U.S. and don’t rely on overseas supply chains, our lead times are predictable. Most standard projects ship in 2–4 weeks, while larger or fully custom jobs rarely exceed 5 weeks. And we don’t leave you guessing: we provide a production timeline upfront and update you at every milestone. That transparency is a big reason many of our clients treat us more like a partner than a vendor.

We’re in South Florida. Salt, humidity, brutal sun — will these window sills hold up, or will we be replacing them in five years?

Foam thrives in harsh climates — in fact, that’s one of its greatest strengths. Its closed-cell structure resists moisture absorption (under 2%), so it doesn’t swell, rot, or delaminate. Our protective coatings are UV-stable and salt-resistant, and many of our projects near the coast are still performing beautifully more than a decade later.

One beachfront condo project in Fort Lauderdale is a great example: installed in 2011, those sills haven’t faded, cracked, or warped — even after endless hurricane seasons.

I’m still unsure about the style direction for my project. Will you help us figure it out, or do we need a fully finished design before coming to you?

You don’t need a finished design at all — we love being involved early. Many of our best projects started as rough sketches or mood boards. We’ll collaborate with you to develop profiles that fit your vision, budget, and technical needs. It’s one of our favorite parts of the job: helping clients go from concept to construction-ready reality. And because we’ve seen thousands of designs over the decades, we can offer guidance that saves time and avoids costly rework down the line.

How fast is installation?

Usually about 165–190 linear feet in four workdays. On a particularly tight downtown site, an entire run was installed with just a small crew and no heavy equipment — and still finished ahead of schedule.

Will it feel quieter next to a busy road?

Absolutely. Most people notice the difference the first evening. The shell reflects harsh noise while the foam core absorbs the rest. At a project near a Miami expressway, the change was dramatic enough that residents started using their outdoor space again.

Can you match our façade color exactly?

Yes — we’re obsessive about that. Foam takes acrylic with precision, and we routinely achieve perfect visual matches. A historic property in Savannah once had us match an aged brick tone, and even the neighbors assumed the new wall was original masonry.

What if we have a big grade change?

No problem. Foam follows contours far more easily than concrete or masonry. Instead of awkward steps, we can create smooth transitions that maintain visual calm and proper drainage.

Will a white finish last in coastal weather?

It will if the system is specified correctly. With the right coating and finish, walls along the Gulf Coast have stayed chalk-free and color-true for years. Occasional rinsing is usually all the maintenance required.

Are foam panels strong enough for high winds?

Yes. When everything is engineered thoughtfully — from precise anchor spacing to slightly shortened modules in the most exposed spots — the fence doesn’t behave like a fragile structure, but like a seasoned sailor standing firm on deck in the middle of a storm. Even hurricane-level coastal winds don’t faze it: it doesn’t shift a millimeter, doesn’t crack, and never gives in to the elements. At one property near Daytona Beach, the fence looked as if it had been installed yesterday, even after an entire storm season — perfectly straight, steady, and untouched. It’s more than just strength; it’s a quiet confidence you can feel when you look at it, as if the architecture itself is saying, “I’m right where I belong — and I’m not going anywhere.”

Can we include a recessed logo without a billboard look?

Definitely. Because foam is so easy to shape, recessed details feel purposeful rather than forced. One Atlanta property incorporated its logo into a shadowed niche with subtle lighting — the effect is elegant by day and welcoming at night.

Is six feet high enough for privacy?

Often, yes. Especially when paired with strategic planting. And if local codes require more, we can add height without creating a fortress-like presence.

What do you need to provide a quote?

Length, height, a style cue, and a few photos. Include a color sample early and we can return strike-offs with the estimate — speeding approvals by up to a week.

We want a wood look without the upkeep.

We can achieve that easily. Slim aluminum fins paired with textured foam surfaces create the warmth and light play of wood without rot, refinishing, or fading. On one residential project, the “wood” still looked fresh three seasons later with nothing more than a garden hose rinse. The result was as visually appealing as natural wood and perfectly matched the desired look of the homeowner.

& specification catalog

Get the definitive guide to our custom decorative architectural foam shapes. This free catalog is packed with hundreds of design profiles, detailed technical specifications, and real-world project applications.

Have a project in mind?

Our dedicated specialists are ready to collaborate with you, turning your concept into a detailed plan with a transparent budget. Let’s bring your vision to life!

More architectural shapes

We provide architects, builders, and homeowners with turnkey decorative elements that transform any project — fast, easy, and cost-effective.

Sills & bands

Architecture is more than aesthetics. It’s a precise language of form, proportion, and purpose that shapes how people interact with a space. And in that language, it’s often the small, precisely designed elements — like modern window sills— that shape how people see and experience a building.

They don’t just finish a facade; they increase its value, boost its performance, and transform the whole project into something that looks intentional and high-end, especially with live plants. Decorative Architectural Shapes has been in this industry long enough to see trends come and go — from breakthrough innovations to short-lived fads — and one thing remains clear: well-designed sills and bands consistently make the difference between a building that’s simply built and one that’s truly remembered. They’re the punctuation marks of a design — the subtle lines and contours that transform a structure from something ordinary into something unforgettable.

We’ve seen this play out time and time again. In downtown Savannah, a once-tired 1920s townhouse came back to life when we replaced its cracked masonry with lightweight exterior sills. In Miami, a luxury condominium complex shifted from “generic contemporary” to “architectural statement” thanks to sleek, continuous bands framing its panoramic windows. These aren’t just products — they’re the details that define a project’s soul.

Clients don’t come to us for “sills.” They come to us when aesthetics must meet engineering. When the budget can’t bend, but expectations are sky-high. When schedules are tight, but compromise is not an option. That’s where we thrive — designing solutions that deliver both beauty and performance without a single unnecessary trade-off.

What decorative sills are — and why they matter so much

It’s easy to underestimate a window sill. Most people think of it as a functional necessity — a drip ledge, a water diverter. And yes, that’s part of the story. But in the hands of an architect, exterior sills are far more: they define shadow lines, guide the eye across a facade, and give a building its sense of proportion.

They also solve practical problems elegantly. Sills keep water from creeping into wall assemblies, protect finishes from weather, and extend the lifespan of the building envelope. And when made from foam, they do it without adding weight or complexity to the structure.

The same is true indoors. Modern interior window sills can act as subtle transitions between materials, create visual hierarchy in a room, or even serve as minimalist ledges that tie interior and exterior design together. Window sills are small details of interior design, but like all good details, window sills are what make a design feel intentional, cohesive, and complete.

How architecture and sills evolved

When we opened our first workshop in the late ’90s, window sills were heavy, poured concrete or carved stone. Window sills were beautiful but limiting in interior design. Shipping costs were high, installation required cranes, and customization was nearly impossible.

Then the design landscape shifted. Clients started asking for cleaner lines, larger windows, faster builds, and lower energy costs. Architects needed materials that could keep up — materials that were flexible, precise, and fast without sacrificing quality. That’s when foam moved from “alternative” to “essential.”

We still smile remembering one of our earliest projects in Jacksonville: a neoclassical apartment building with ornate, three-piece window surrounds. At the time, replicating those in stone would’ve blown the budget and doubled the construction time. With foam, we recreated the look of the room perfectly — 80% lighter, 50% faster to install, and 30% cheaper. That project taught us an important lesson: innovation isn’t about changing the look. It’s about changing the way you achieve it.

Foam technology: a closer look at the advantages

Calling foam “lightweight” is accurate, but it doesn’t tell the full story. The real reason window sills are revolutionizing architecture is because they solve multiple engineering challenges at once. Here’s how:

| Performance Metric | Technical Specification & Field Impact |

|---|---|

| Weight Efficiency | A 6-foot sill profile weighs approximately 4–6 lbs (1/10th the weight of stone). This eliminates the need for structural reinforcement, heavy machinery, or excessive facade stress. |

| Moisture Resistance | Closed-cell structure absorbs less than 2% water by volume. Elements do not crack, swell, or deteriorate even after decades of environmental exposure. |

| Thermal Stability | Expansion rate of roughly 0.02% per °F (3x less than PVC). High dimensional stability prevents buckling and joint separation in extreme temperature swings. |

| Structural Strength | Coated profiles handle over 60 psi in compression and 100+ psi in tension. They resist wind pressure and installation impacts without deforming or breaking. |

| Longevity | Consistent 30+ year service life. UV-resistant finishes protect color integrity and prevent surface cracking, even in harsh coastal climates. |

We often explain it like this: stone belongs to another era — beautiful, yes, but heavy, stubborn, and demanding every step of the way. Foam, on the other hand, is built for how we design and build today: it’s light on the structure, smart in performance, and engineered to meet the real pressures of modern construction without slowing anything down.

Why traditional materials don’t cut it anymore

Stone and concrete still have a place, but they’re no longer the default. They’re heavy, they require reinforced anchoring, they slow down construction schedules, and they cost more — not just in materials, but in logistics, labor, and equipment.

Window sills made from foam eliminate those headaches:

- Window sills show up ready to go — no cutting, tweaking, or extra prep needed on site.

- You won’t need heavy equipment or special structural work to put them in place. There’s no renting cranes, reinforcing walls, or redesigning the foundation just to handle their weight. They’re light enough to be handled by a small crew, which keeps installation simple, fast, and budget-friendly.

- Window sills open up a level of design freedom that simply isn’t possible with rigid, traditional materials. Complex curves, deep overhangs, dramatic shadow lines, and seamless continuous runs — all of it can be achieved without the structural limitations or fabrication constraints that come with stone or concrete. This flexibility gives architects and designers the ability to experiment boldly and push creative boundaries without compromise.

- Window sills also have a dramatic impact on project economics, reducing total installed costs by as much as 20–35%. That’s not just due to the lower material price — savings compound across shipping, labor, and equipment, and the faster, cleaner installation often frees up crews to move on to other scopes of work ahead of schedule. In large-scale developments, this can translate into hundreds of thousands of dollars in avoided costs.

- And at the end of the day, they give back something even more valuable: time. And in construction, time is everything.

Where sills shape architecture’s identity and performance

Residential applications: precision and performance

In residential projects, window sills are more than decorative details of the room— they protect facades from moisture, manage water runoff, and define clean visual lines. Lightweight foam components reduce load on walls, integrate easily with common cladding systems, and speed up installation.

On a recent 200-unit development in Orlando, we supplied pre-fabricated decorative window sills labeled by elevation and ready to install, which cut labor time and ensured a uniform, precise finish across the entire project.

We remember a waterfront property in Gainesville that perfectly captures this. The client, a retired pilot, wanted a home that felt “as light as air.” Heavy masonry was out of the question. Instead, we designed ultra-slim decorative window sills with a soft limestone texture, stretching nearly 8 feet in single runs. The result was striking: shadow lines that danced across the facade at sunset, subtle depth without visual heaviness — and a delighted client who said the house felt “like it was floating.”

Commercial projects: where performance drives design

Commercial architecture is a different beast — tighter schedules, stricter codes, higher expectations. Foam thrives here too, delivering scalable solutions without compromising aesthetics.

A great example: a 12-story hotel in downtown Atlanta. The architect’s concept relied on continuous horizontal bands that wrapped the facade like ribbons. In stone, the design was impossible without breaking the budget. With foam, we engineered seamless profiles that met both structural and design requirements. Installation in the room took half the projected time, and five years later, the building still looks like it was finished yesterday — not a single maintenance call.

We see this across office campuses, retail centers, educational buildings, houses and more. Foam components allow developers to focus on what matters — tenant experience, design identity, long-term value — instead of sweating logistics.

How we work: precision, partnership, peace of mind

We don’t ship boxes. We deliver solutions. Every project includes:

- Detailed 3D models of window sills and visualizations for early design decisions of window sills.

- Full technical documentation for window sills: shop drawings, section details, data sheets.

- Installation-ready components for window sills, labeled, packaged, and precisely sized.

We believe installation should feel like assembly, not construction. Our goal is that when your team opens the crate, everything “just fits.” No cutting. No improvisation. No surprises.

Why Decorative Architectural Shapes is more than a supplier

Clients stay with us project after project not because we sell foam — but because we make their jobs easier.

- 25+ years of architectural expertise.

- Manufactured in the United States.

- Design freedom.

- Predictable lead times and rock-solid logistics.

- Expert guidance from concept through installation.

But beyond the bullet points, there’s something else. We care. We care about the architect trying to make their design vision a reality. We care about the contractor racing a deadline. We care about the developer whose reputation rides on the finished result. And we never forget that when you choose us, you’re trusting us with your vision.

& specification catalog

Get the definitive guide to our custom decorative architectural foam shapes. This free catalog is packed with hundreds of design profiles, detailed technical specifications, and real-world project applications.

Have a project in mind?

Our dedicated specialists are ready to collaborate with you, turning your concept into a detailed plan with a transparent budget. Let’s bring your vision to life!