About our

stucco mailbox systems

Our systems deliver the timeless look of solid masonry without the weight, cost, or complexity.

The stucco mailbox, engineered for an unforgettable first impression

A mailbox is more than a container; it’s an architectural statement. Secure, elegant, and virtually maintenance-free, our stucco mailboxes are crafted from a high-density, lightweight composite to replicate a solid masonry column without the engineering challenges. Perfect for luxury residences, entire housing developments, and prestigious commercial properties, these systems add a powerful statement of quality and attention to detail from the moment someone arrives.

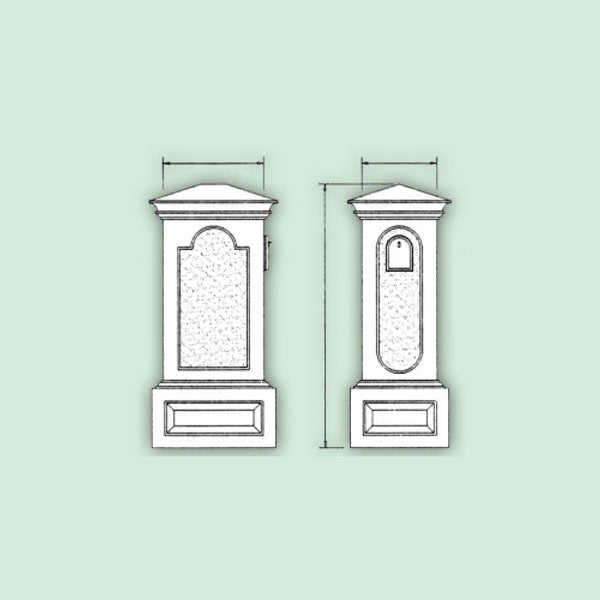

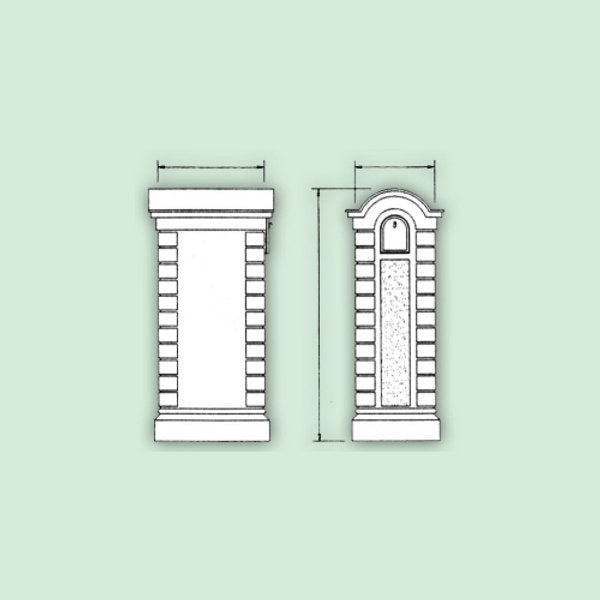

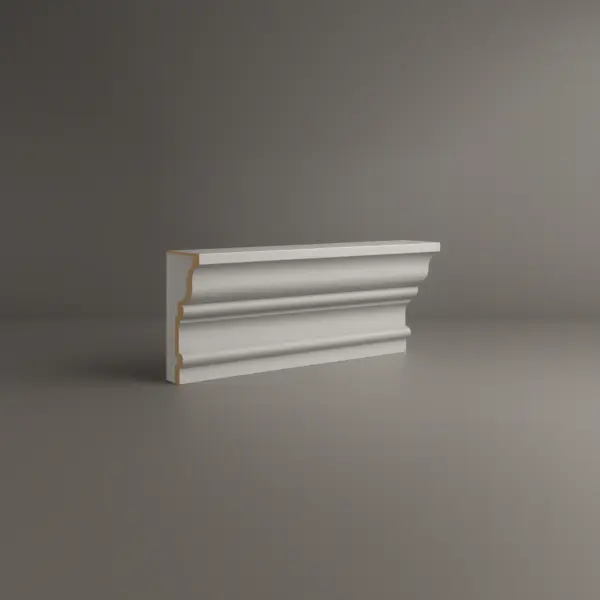

Each stucco mailbox is a precision-engineered unit, consisting of:

- A Structural Core: A solid, high-density EPS foam core, precision-cut for flawless geometry and stability.

- An Integrated Mailbox Unit: Secure, regulation-compliant mailboxes seamlessly built into the structure.

- An Architectural Finish: A durable, textured stucco finish that can be matched to any property’s exterior.

Get a fully finished architectural element that installs in minutes, not days.

The science behind a mailbox that lasts a lifetime

Our architectural stucco mailboxes are built from an advanced composite of materials engineered for extreme longevity and curb appeal. At the heart of each mailbox is a structural, high-density Expanded Polystyrene (EPS) foam core that is precision-cut for perfect balance and form.

This core is then completely encapsulated in our signature polyurea hard coat—a spray-applied elastomer that creates a seamless, waterproof, and impact-resistant shell. This isn’t just a coating; it’s armor. This process transforms the lightweight foam into a monolithic structure with incredible strength, ready to withstand everything from weed whackers to harsh weather.

The exterior is a fully integrated, architectural mailbox stucco finish that provides the authentic texture of masonry and superior resistance to weathering, UV rays, and cracking. This advanced construction makes our systems robust, elegant, and exceptionally long-lasting.

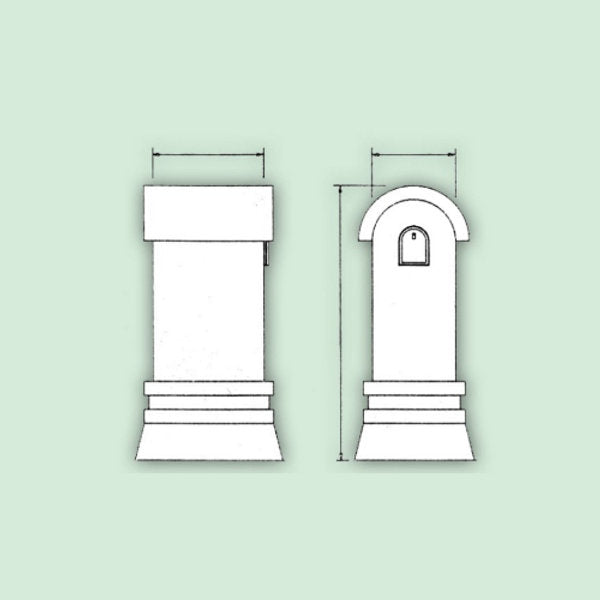

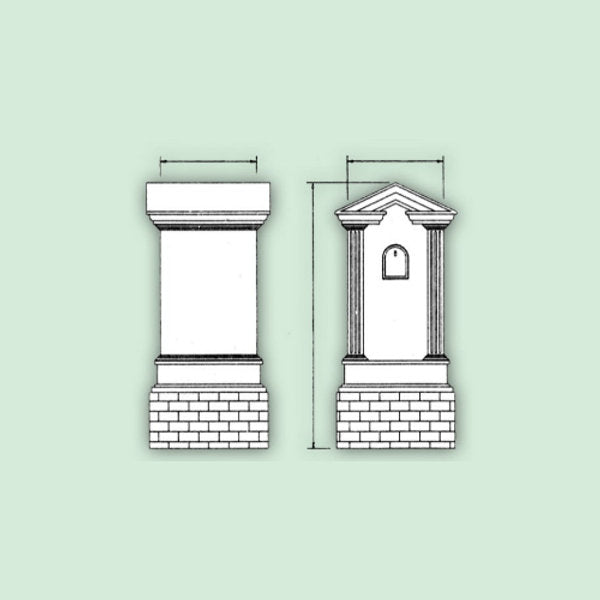

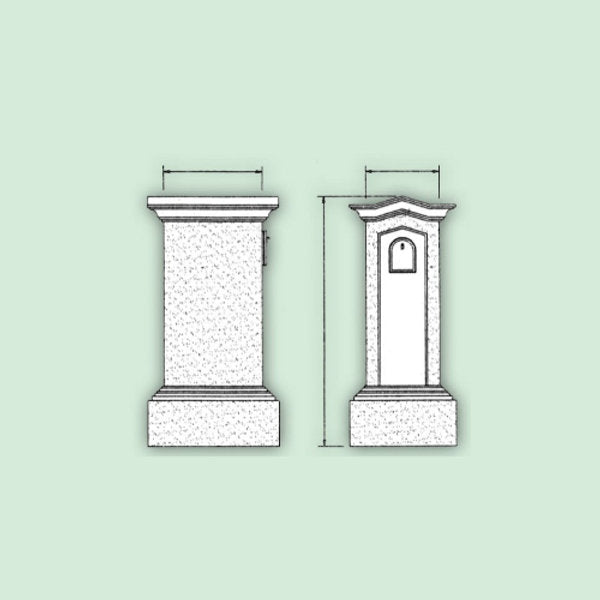

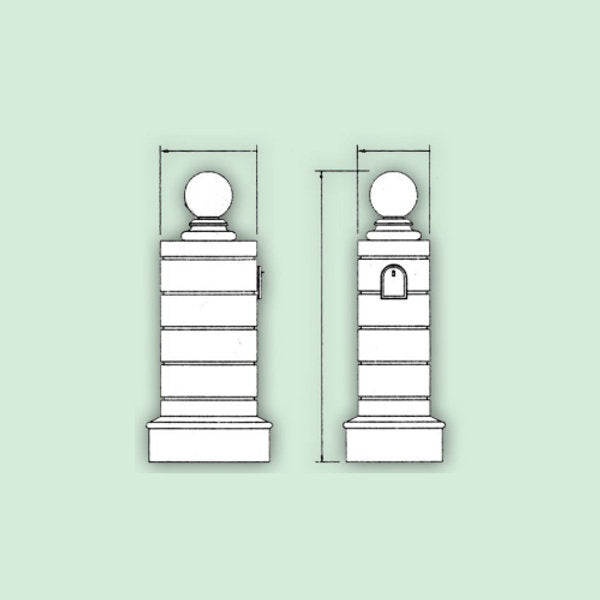

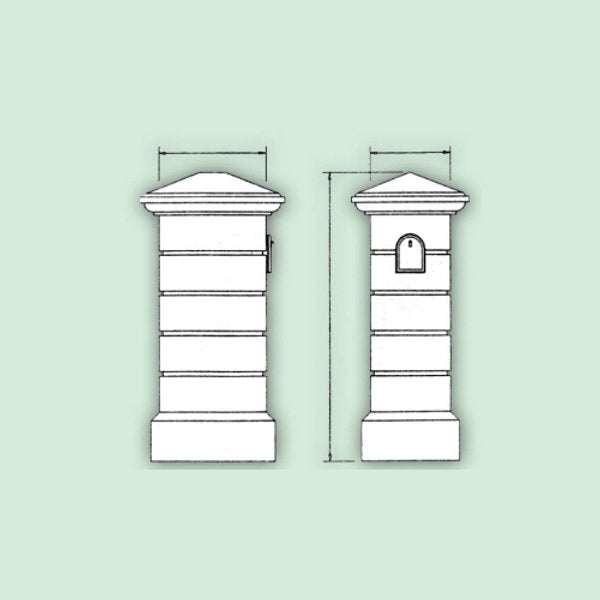

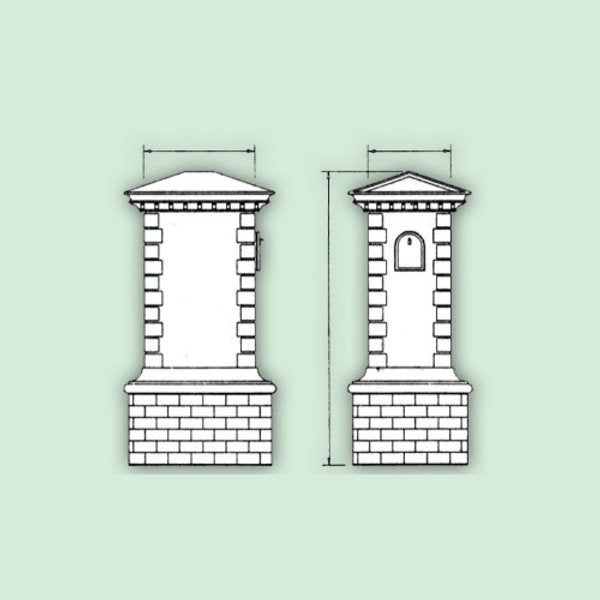

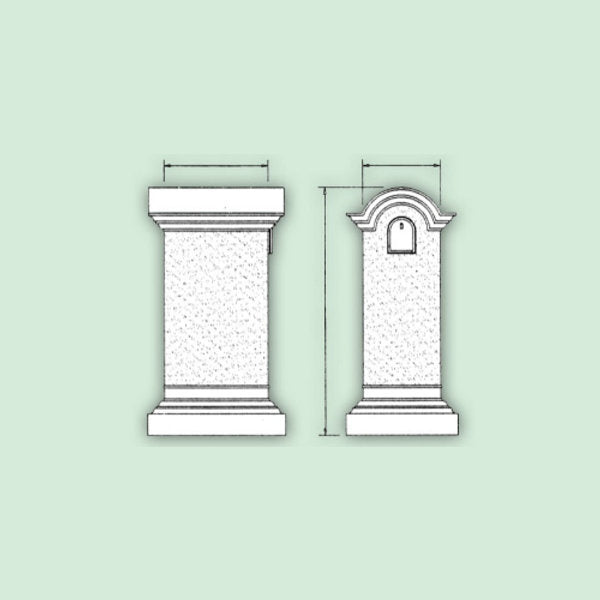

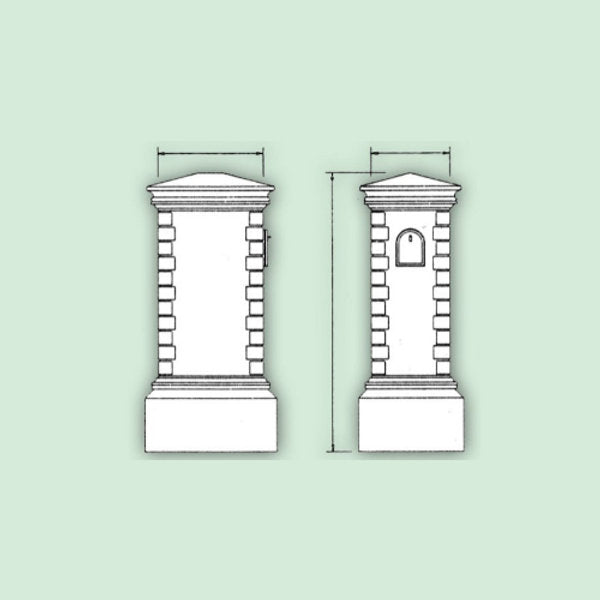

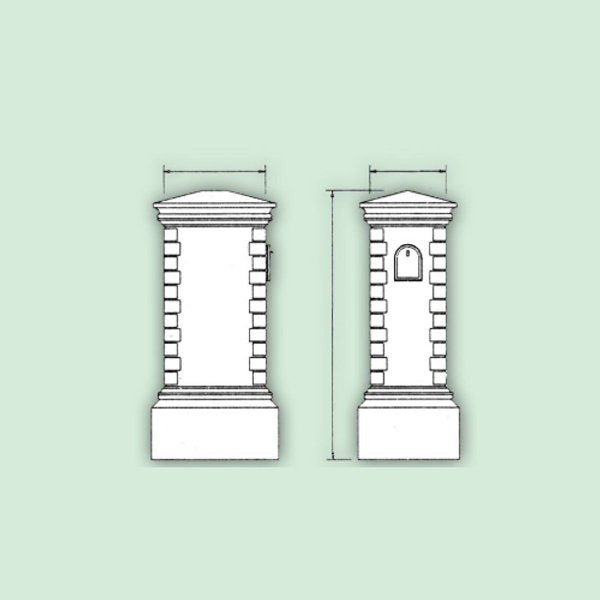

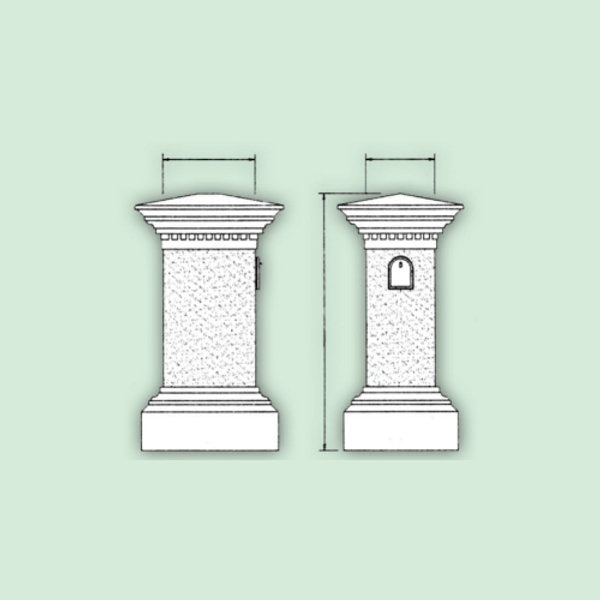

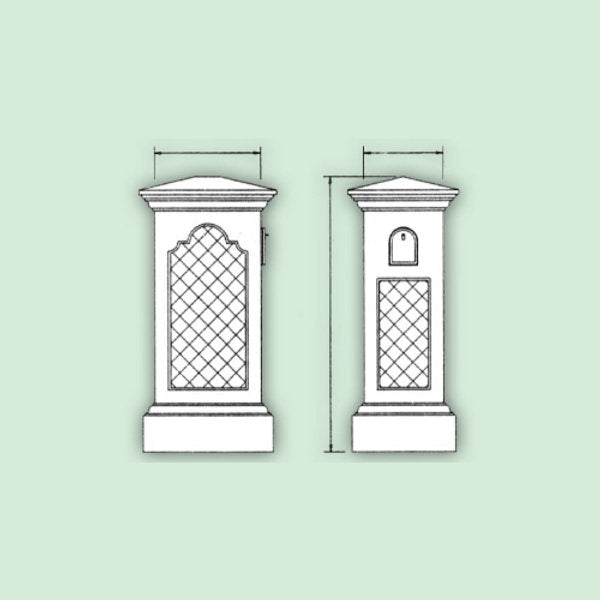

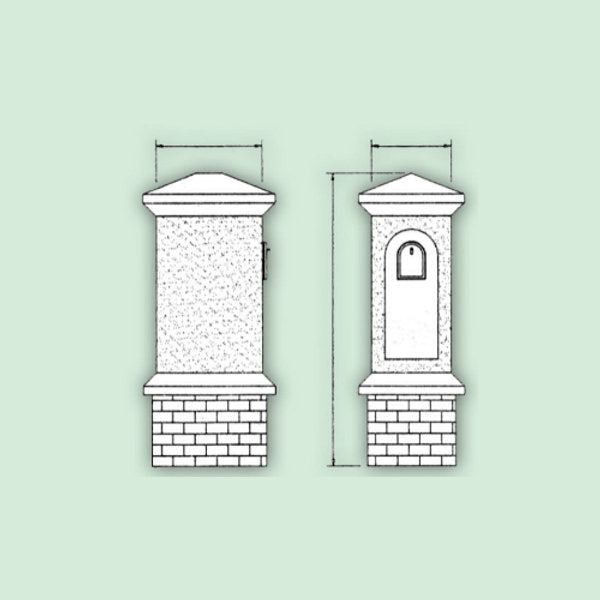

Assortment of

stucco mailboxes

EPS stucco mailboxes vs. traditional masonry:

The Royal Foam advantage

Stop settling for heavy, outdated materials that crack and stain. Choose a lightweight, durable, and fully customizable stucco mailbox—built to last and proudly made in the USA.

Requires a concrete footing, skilled masons, and days of labor, driving up costs.

Multi-day installation slowed by mortar curing and weather delays.

Prone to cracking, water damage, and staining. Requires ongoing repairs.

Design is limited by materials. Customization is slow and cost-prohibitive.

High upfront costs for materials and labor, plus ongoing maintenance expenses.

No heavy machinery or deep foundation required.

Arrives fully prefabricated. Installs in minutes, accelerating project timelines.

Waterproof polyurea shell resists cracking and rot. Zero maintenance for its 80-100 year lifespan.

Unlimited design freedom with CNC fabrication. If you can design it, we can build it.

Lower total project cost due to huge savings on labor, equipment, and foundation.

Сustom stucco mailboxes

How to order your architectural stucco mailbox

From your initial concept to job site delivery—our process is transparent, fast, and engineered for perfection.

It all begins with a deep dive into your project. We work as your technical partner to transform creative intent into a solid, actionable plan.

- Analyze Your Inputs: We review your architectural plans, CAD files, sketches, and inspirational images to understand your design from every angle.

- Define the Scope: In a collaborative consultation, we discuss the project’s aesthetic goals, site conditions, and technical requirements to ensure a perfect fit.

- Establish a Technical Blueprint: We finalize all specifications, from dimensions to finish textures, creating a clear roadmap for fabrication that aligns perfectly with your vision.

We bridge the gap between concept and cost, providing you with the clarity and confidence to move forward.

- Receive a Detailed 3D Visualization: We create and send you a precise 3D model, allowing you to see exactly how your custom architectural elements will look before production begins.

- Get a Transparent, Itemized Proposal: You receive a clear, comprehensive quote with no hidden fees. We believe in total transparency, so you know exactly what you’re investing in.

- Maintain Complete Control for Final Approval: We don’t proceed until you are 100% satisfied. You have the final say on the design and budget before we move to the next stage.

This is where your approved design becomes a physical reality, crafted with an obsessive focus on quality in our 45,000 sq. ft. workshop.

- Execute with Robotic Accuracy: Our state-of-the-art CNC hot-wire machines carve your architectural elements with flawless precision, matching your approved 3D models to the exact specification.

- Armor for a Century of Performance: Our skilled artisans apply our signature Polyurea hard coat, creating a seamless, impact-resistant, and weatherproof shell designed for decades of durability.

- Verify Through Rigorous Quality Control: Every single piece undergoes a multi-point inspection to ensure it meets our exact standards for shape, finish, and structural integrity.

Our commitment extends all the way to your job site, ensuring a smooth and successful installation.

- Protect with Secure, Custom Crating: We build specialized shipping crates for every project, guaranteeing your elements arrive in pristine, ready-to-install condition.

- Streamline Your Installation: Your pieces are delivered pre-assembled and lightweight, designed to slash on-site labor time and eliminate the need for heavy machinery.

- Support Your Crew to the Finish Line: We provide detailed installation guides and offer live Zoom support to answer your team’s questions, guaranteeing a perfect final fit.

It all begins with a deep dive into your project. We work as your technical partner to translate creative intent into a solid, actionable plan.

- Analyze Your Inputs: We review your architectural plans, CAD files, sketches, and inspirational images to understand your design from every angle.

- Define the Scope: In a collaborative consultation, we discuss the project’s aesthetic goals, site conditions, and technical requirements to ensure a perfect fit.

- Establish a Technical Blueprint: We finalize all specifications, from dimensions to finish textures, creating a clear roadmap for fabrication that aligns perfectly with your vision.

We bridge the gap between concept and cost, providing you with the clarity and confidence to move forward.

- Receive a Detailed 3D Visualization: We create and send you a precise 3D model, allowing you to see exactly how your custom architectural elements will look before production begins.

- Get a Transparent, Itemized Proposal: You receive a clear, comprehensive quote with no hidden fees. We believe in total transparency, so you know exactly what you’re investing in.

- Maintain Complete Control for Final Approval: We don’t proceed until you are 100% satisfied. You have the final say on the design and budget before we move to the next stage.

This is where your approved design becomes a physical reality, crafted with an obsessive focus on quality in our 45,000 sq. ft. workshop.

- Execute with Robotic Accuracy: Our state-of-the-art CNC hot-wire machines carve your decorative architectural shapes with flawless precision, matching your approved 3D model to the millimeter.

- Armor for a Century of Performance: Our skilled artisans apply our signature Polyurea hard coat, creating a seamless, impact-resistant, and weatherproof shell designed for decades of durability.

- Verify Through Rigorous Quality Control: Every single piece undergoes a multi-point inspection to ensure it meets our exacting standards for form, finish, and structural integrity.

Our commitment extends all the way to your job site, ensuring a smooth and successful installation.

- Protect with Secure, Custom Crating: We build custom shipping crates for your elements, ensuring they arrive on-site in pristine, ready-to-install condition.

- Streamline Your Installation: Your pieces are delivered pre-assembled and lightweight, designed to slash on-site labor time and eliminate the need for heavy machinery.

- Support Your Crew to the Finish Line: We provide detailed installation guides and offer live Zoom support to answer your team’s questions, guaranteeing a perfect final fit.

Our project gallery

Engineered solutions for every project

We partner with industry leaders to deliver architectural mailboxes that enhance curb appeal and property value.

We provide standardized, elegant stucco mailboxes for entire communities, ensuring a unified, high-end aesthetic that increases property values from day one.

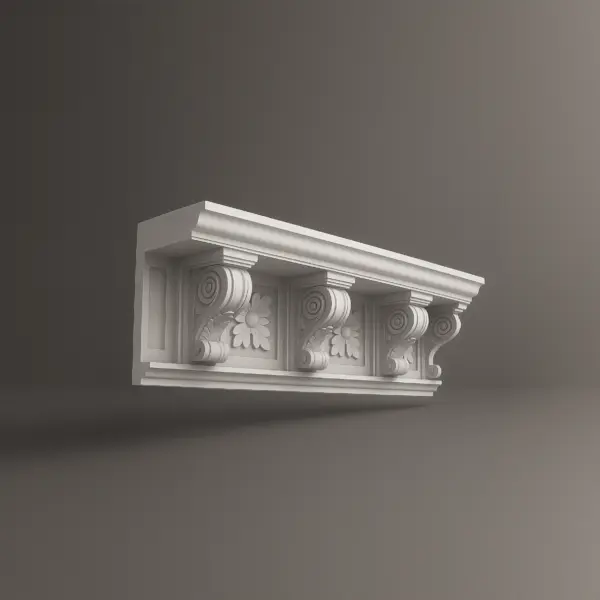

Achieve the perfect finishing touch. We fabricate custom stucco mailbox designs to your exact CAD specifications, from a minimalist modern stucco mailbox to ornate classical columns.

Elevate your brand’s physical presence. A custom architectural mailbox communicates stability and professionalism for corporate campuses, medical centers, and retail locations.

Create the ultimate first impression. Our systems provide the curb appeal and design-forward stucco mailbox ideas needed to build a truly custom and impressive entryway.

Before and after:

A strategic transformation

Discover our workMore than a mailbox—it's your property's handshake

A mailbox is more than just a boundary marker—it’s the first physical interaction a client, guest, or resident has with your property. A well-engineered stucco mailbox instantly communicates quality, security, and meticulous attention to detail, setting the tone before anyone even steps out of their car.

- A Professional Image that Builds TrustA solid, monolithic mailbox stucco column adds an air of permanence and prestige. It shows you invest in quality down to the smallest detail, which helps establish credibility and confidence.

- A Durable, Fire-and-Forget SolutionForget rust, rot, and cracking mortar. Our stucco mailboxes are engineered to withstand harsh weather, UV rays, and time—staying beautiful year after year with zero maintenance. This low total cost of ownership is a smart investment for any property.

- Custom Design for Your Architectural IdentityYour entryway should be an extension of your design vision. With a variety of textures, finishes, and the ability to integrate custom address numbers or logos, our mailbox systems can be tailored to align perfectly with your property's architectural style.

Client testimonials

From your first idea to the final installation — our process is clear, fast, and designed to make every detail simple.

FAQ

Can you match the stucco mailbox to my wall color?

Yes — we do it often. A Tampa homeowner sent us a small plaster chip, and we matched it perfectly. “It looks like it grew out of the wall,” she said.

How long do stucco mailboxes last?

Over 20 years. One of our early Georgia models still looks new after 16 years.

Can you add lighting or address numbers?

Absolutely. We’ve added LED strips, acrylic digits, even solar lighting. A Naples project featured glowing house numbers that became a local landmark.

What’s the average stucco mailbox cost?

About 25–30% less than stone, with longer lifespan and easier installation.

Can I order several for a community project?

Yes. We recently made 28 mailbox stucco units for a luxury development near Atlanta — all unique, yet cohesive in design.

How do I maintain it?

Just rinse with water — no chemicals, no repainting needed.

Do you offer a warranty?

Yes — a full 20-year warranty on structure and coating.

Can I see samples first?

Of course. We provide both physical samples and digital renderings before production.

Are they suitable for commercial properties?

Definitely. Around 70% of our clients use our elements for hotels, offices, and mixed-use projects — including Amazon and Red Bull.

We’re working on a beachfront project — are your finishes reliable in marine conditions?

Our marine-grade coatings resist salt, humidity, and UV. In Destin, Florida, mailboxes along the promenade still look perfect after seven years of ocean exposure.

Can you recreate historic designs?

Yes. We restored a 1920s-style oak mailbox for a Savannah renovation — now it’s a highlight of the property.

Do you handle resorts or gated communities?

All the time. In Palm Beach, we created 35 custom foam mailboxes engraved with villa names for the curb appeal of the district. Guests take photos daily — they’ve become part of the resort’s charm.

What if I’m unsure about design?

No problem. We’ll help refine your vision with examples, sketches, and mockups until it feels right.

Do you work directly with homeowners?

Absolutely. Many of our best projects began with homeowners who simply wanted something special.

Have you ever built something truly unique?

Yes — a client from Key West asked for a foam mailbox shaped like a coral reef sculpture. It sounded wild, but we made it work. Now it’s the most photographed mailbox in the Keys.

What if we need a fast turnaround?

We specialize in it. A Miami developer once called on Friday needing ten foam mailboxes within a week — we delivered on time, flawless and ready to install.

& specification catalog

Get the definitive guide to our custom decorative architectural foam shapes. This free catalog is packed with hundreds of design profiles, detailed technical specifications, and real-world project applications.

Have a project in mind?

Our dedicated specialists are ready to collaborate with you, turning your concept into a detailed plan with a transparent budget. Let’s bring your vision to life!

More architectural shapes

We provide architects, builders, and homeowners with turnkey decorative elements that transform any project — fast, easy, and cost-effective.

Stucco mailboxes

Some details are so ordinary we stop seeing them — until they’re done right. Take a mailbox, for example. Most people think of it as just a box for mail. But imagine the first thing your guests or clients notice isn’t the door or the landscaping — it’s that single detail that quietly says someone cared. That’s what our stucco mailboxes do. They turn a small necessity into a design moment — subtle, sculptural, and unforgettable. Once you’ve seen one, you can’t unsee the difference.

For over 25 years, we’ve been building these quiet architectural heroes. We’ve seen styles evolve — heavy stone columns fade into sleek geometry, baroque curves give way to minimalism. Yet the desire for authenticity never changed. People still want a stucco mailbox that feels intentional, personal, and built to last.

Beyond a box: what a stucco mailbox really is

A stucco mailbox isn’t just a box for mail — it’s a small piece of architecture, crafted with intention and designed to speak the same language as your home. Instead of blending in as background detail, it becomes a quiet accent — a finishing touch that completes the façade like punctuation at the end of a sentence.

At its core lies high-density architectural foam — strong yet feather-light, resistant to weather, humidity, and time itself. Around it, we build layer upon layer of reinforced coatings, much like an artist layering pigments on a canvas. Each surface is finished with hand-textured stucco that can echo the feel of natural plaster, aged stone, or something entirely your own.

The result is a mailbox stucco that doesn’t just resist the weather — it works with it. The surface holds a quiet warmth, the kind architects notice when light hits just right. It feels alive in a way: soft in the morning sun, sharper by noon, and almost glowing by dusk — like it has its own rhythm, quietly shifting with the day.

Materials for great design

All our stucco mailboxes are made locally in Florida under strict quality control. Each piece goes through a precise process — from foam cutting and reinforcement to multi-layer finishing.

This process guarantees precise geometry, uniform surface texture, and lasting structural stability. Each mailbox is engineered to exact tolerances, ensuring that every edge, curve, and junction aligns perfectly once installed. The lightweight composition of architectural foam simplifies logistics and installation, reducing both time on-site and the need for heavy equipment.

Our proprietary coating system is formulated to withstand challenging climates — resistant to humidity, UV exposure, and salt-laden coastal air. One project in Clearwater put this durability to the test: a series of mailboxes positioned less than a hundred feet from the shoreline, exposed to constant ocean wind. After five years of sun, salt, and storms, their finish remains unchanged — a quiet, measurable testament to material integrity and precision manufacturing.

Modern geometry

Modern foam mailbox designs are all about quiet confidence — pure lines, crisp geometry, and a finish that speaks for itself. When a Sarasota client asked for something minimal but bold, we created a sleek rectangular form with hidden LED lighting and a stainless-steel mail slot. It turned out less like a mailbox and more like a piece of modern architecture — understated, precise, and impossible to overlook.

Signature concepts

Some people don’t just want a mailbox — they want a story cast in stucco. We love that kind of client. The ones who show up with sketches on napkins, screenshots from movies, or a few words that sound more like feelings than specs. That’s where our custom work begins — turning fragments of imagination into something you can touch.

A developer in Miami once came to us with an unusual challenge: “I want every villa to feel different, but they all need to belong to the same family.” So, we built a modular design system — same proportions, shared geometry, but with details that changed like accents in a familiar voice. It was unity without repetition, and when the row was complete, the effect was stunning — individuality inside order, just like the city itself.

Then there was a homeowner from Tallahassee who wanted a mailbox on the ground level of his house – that felt like memory. His grandfather’s old limestone farmhouse was gone, but he still remembered the way the afternoon sun warmed the stone. We recreated that texture by hand, softening the edges, tinting it with a dusty gold undertone. When we installed it, he touched the surface, paused, and said quietly, “This feels like home again.”

That’s what we live for — not just creating objects, but moments that connect design with emotion.

Smart economics and consistent quality

Because we build locally, the foam mailbox cost stays fair and predictable — no delays, no surprises, just steady quality on schedule.

But the real advantage is the convenience and value you get when you choose our solution.

| Advantage | Technical impact and field reliability |

|---|---|

| Lightweight savings | Easy to ship, handle, and install — cutting costs and time without sacrificing quality. |

| Durable beauty | Our coatings are built to move with the material, not against it. They expand and contract with temperature changes, which prevents microcracks that appear on rigid finishes. Fully weatherproof, they resist moisture, UV rays, and maintain elasticity for years. Even under southern sun or constant humidity, the color and texture stay true. |

| Lower lifetime costs | Maintenance-free for decades — no repainting, no sealing, no repairs. |

| Consistent lead times | We meet schedules, even when demand is high. Last summer, a contractor in Orlando turned to us after another supplier delayed production. Taking over mid-project, we manufactured and delivered forty foam mailboxes in ten days — on time and flawlessly. Working fast without losing precision, we proved that reliability is our strongest guarantee. |

A construction partner from Fort Myers once switched his entire community project to our mailboxes — cutting his logistics budget by nearly 35% and meeting his timeline three weeks early. That’s the advantage of control from concept to crate.

We guide you step by step — from concept to installation

When you work with us, you don’t just “place an order.” You enter a creative-engineering partnership. We walk with you through every stage to ensure precision and peace of mind.

| # | Process Stage | Description and service standards |

|---|---|---|

| 1 | Concept creation and 3D modeling | We start by listening — understanding your vision, your client’s style, and the environment. Then we create 3D models and realistic visuals, so you can see proportions, textures, and finishes before production begins. |

| 2 | Custom design and texture matching | We match materials precisely — stucco, wood, stone, or concrete. One architect from Orlando sent us only a paint swatch, and we recreated the exact façade palette. The mailbox blended so perfectly that visitors assumed it was part of the original build. |

| 3 | Engineering and documentation | Every foam mailbox comes with detailed drawings, assembly guides, and specs. Installation becomes seamless — no guesswork, no rework. |

| 4 | Fabrication and quality assurance | Our process combines craftsmanship with automation. Each stage is tested for accuracy and strength. For a boutique hotel in Naples, we produced twenty modern foam mailboxes with embedded emblems — all inspected and installed without a single adjustment. |

| 5 | Packaging, delivery, and installation support | From our Florida facility, we handle everything. Each piece is safely packed, labeled, and ready to install. Our team provides remote support or coordinates directly with your contractors. |

| 6 | Long-term warranty and care guidance | We offer a 20-year warranty on structure and coating. We also train maintenance teams on care to keep your foam mailboxes pristine for decades. |

Designed for everywhere: where our stucco mailboxes shine

Private residences

From classic villas to modern estates, a foam mailbox becomes part of the home’s personality. In Jacksonville, we built one with motion lighting — it gently illuminates when someone approaches. “It feels like the house says hello first,” the owner said.

Residential communities. Developers trust us for consistency. For a 25-home project near Orlando, we created coordinated designs — same silhouette, unique detailing for each property.

Commercial and hospitality projects

Around 70% of our clients use our architectural pieces in large commercial projects — hotels, offices, full developments. Over the years, we’ve worked with Amazon, Red Bull, and major hotel brands. They rely on us for speed and precision — we can deliver a few custom pieces or hundreds of identical foam mailboxes for an entire complex, each one perfectly consistent. For example, in a Sarasota mixed-use project, we produced over a hundred modern foam mailboxes with engraved numbering — delivered on time, ready to install, and flawless in color and finish.

Coastal and public spaces

Our finishes are built for marine durability. We use professional-grade pigments that resist fading under intense sun. A coastal project in Destin, Florida, tested this — mailboxes placed along a seaside promenade, fully exposed to wind, salt, and spray. Seven years later, the sandstone finish looks as vivid as day one — proof that precision chemistry and craftsmanship can stand up to nature.

Why working with Decorative Architectural Shapes means working smarter

After two and a half decades in architectural manufacturing, we’ve learned one truth: it’s not about selling products — it’s about earning trust through performance.

- Real architectural understanding. We speak the language of architects and builders — proportions, elevations, intent.

- 100% Made in Florida. Local manufacturing means full control, quick turnaround, and guaranteed quality.

- Tailored customization. Every stucco mailbox is made to fit — size, color, finish, every detail. A project in Atlanta needed twelve matching mailboxes in six shades to match the landscape. We delivered on time, and the result looked cohesive, not copied.

- Transparent communication. We provide full drawings, mounting specs, and clear expectations. What’s promised is what arrives.

- 20-year warranty that matters. Real protection backed by materials proven to endure.

- Long-term partnership. We stay with you long after installation — clients reorder years later knowing their designs remain on file.

When you choose us, you’re not just buying stucco mailboxes — you’re choosing reliability, craftsmanship, and peace of mind. Stucco mailboxes — small detail, big impression. Let’s build one that tells your story for the curb appeal of your building.

Ask for a quote or request a sample — and see how we turn small details into architectural highlights.

& specification catalog

Get the definitive guide to our custom decorative architectural foam shapes. This free catalog is packed with hundreds of design profiles, detailed technical specifications, and real-world project applications.

Have a project in mind?

Our dedicated specialists are ready to collaborate with you, turning your concept into a detailed plan with a transparent budget. Let’s bring your vision to life!