About our architectural molding systems

A complete toolkit of lightweight profiles, engineered to bring architectural character to any surface.

Built to define and transform any space

Our decorative molding isn’t just trim; it’s an architectural tool. Crafted from a high-density, lightweight composite core, our moldings empower you to add character, create rhythm, and build visual hierarchy in any environment. From grand, sweeping curves in a corporate atrium to crisp, modern decorative wall molding panels in a boutique hotel, our system is engineered for flawless execution.

Each element is precision-made to serve a distinct architectural purpose:

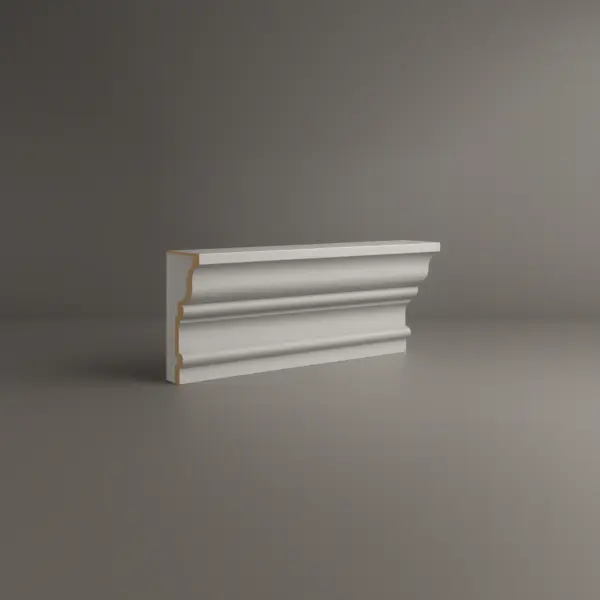

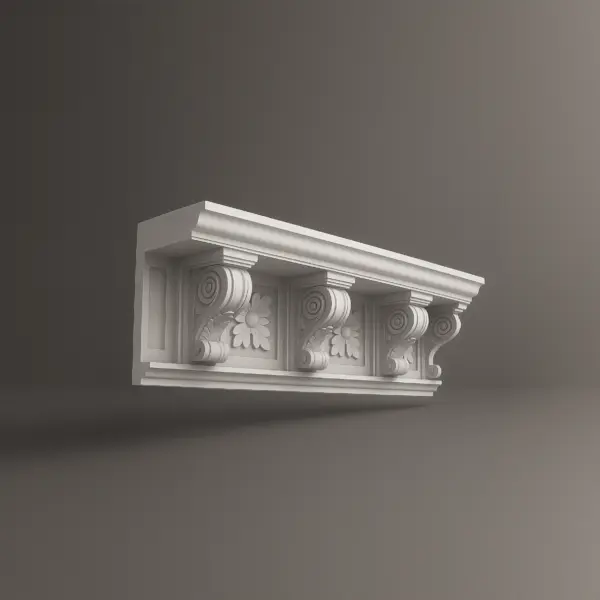

- Crown Molding: To draw the eye upward and add a finishing touch of elegance where wall meets ceiling.

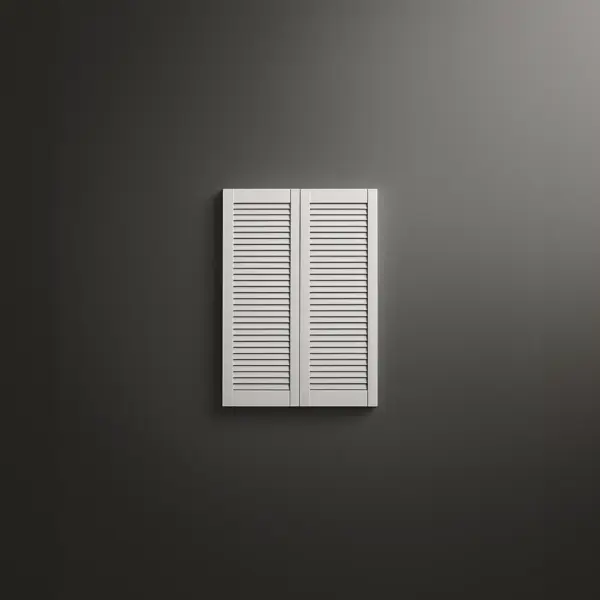

- Wall Molding & Paneling: To turn flat, boring walls into dynamic surfaces with depth and character.

- Casings & Surrounds: To frame windows and doors, transforming simple openings into stately features.

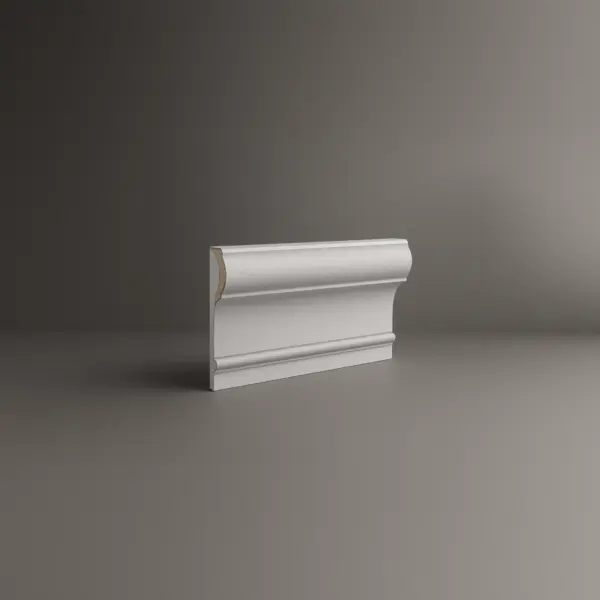

- Baseboards & Chair Rails: To ground the room and provide a durable, aesthetic transition.

Get a modular system that installs with the clean precision your design deserves.

The science behind flawless form and fierce durability

Our architectural moldings interior and exterior systems are born from an advanced material science that leaves traditional methods behind. It starts with a structural, high-density Expanded Polystyrene (EPS) foam core, precision-cut by CNC routers to match your exact CAD files. Every curve, every edge, every detail is perfect from the start.

But the real magic is the armor. We encapsulate this lightweight core in our signature polyurea hard coat. This spray-applied elastomer creates a seamless, impact-resistant, and completely waterproof shell. This isn’t just foam anymore; it’s a monolithic composite with incredible strength that laughs at dents, moisture, and time.

The final surface is a smooth, paint-ready finish that provides the perfect canvas for your color palette. This advanced construction ensures your decorative molding is not only beautiful on day one but stays that way for decades.

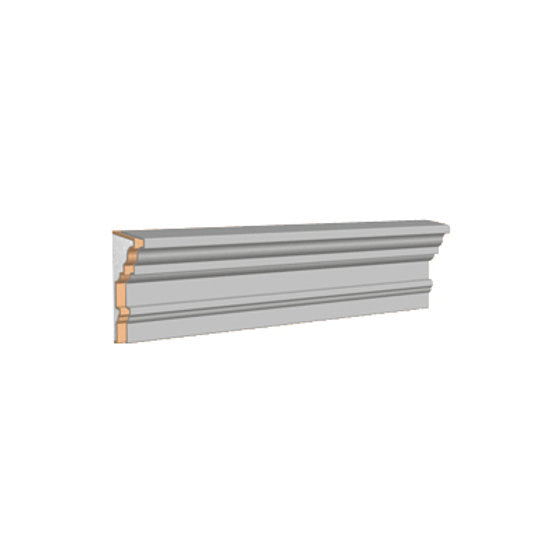

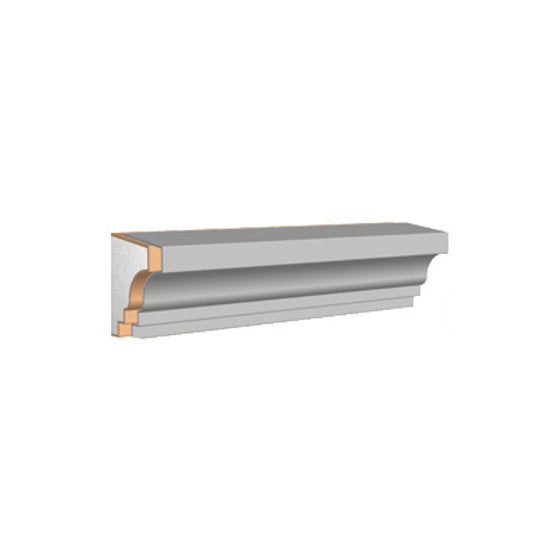

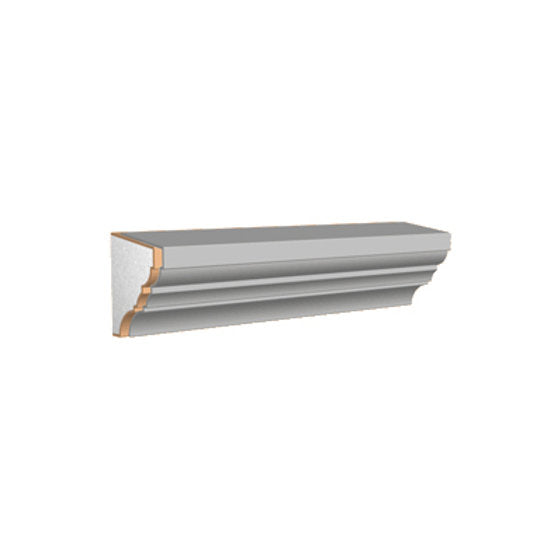

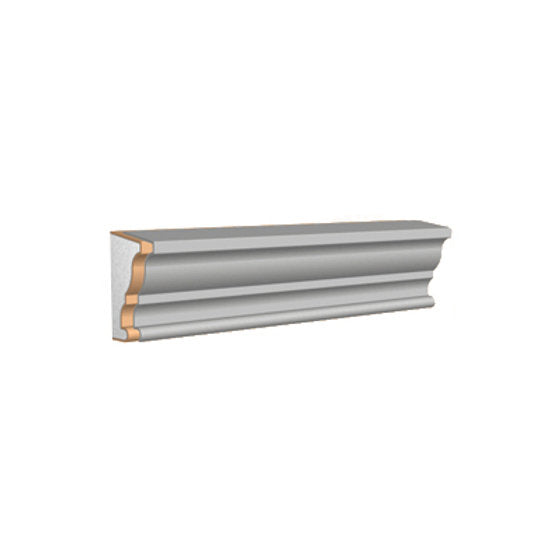

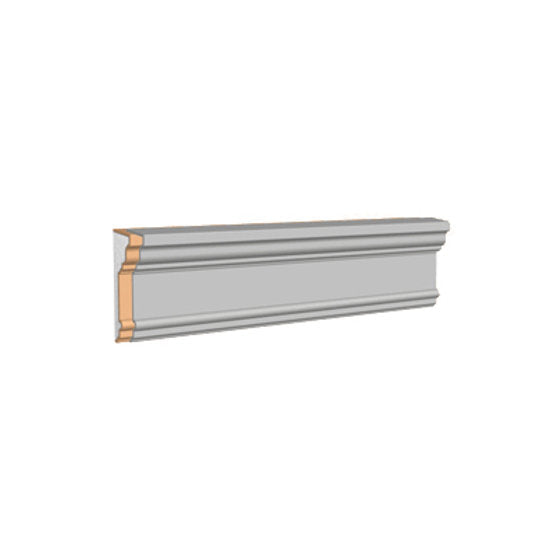

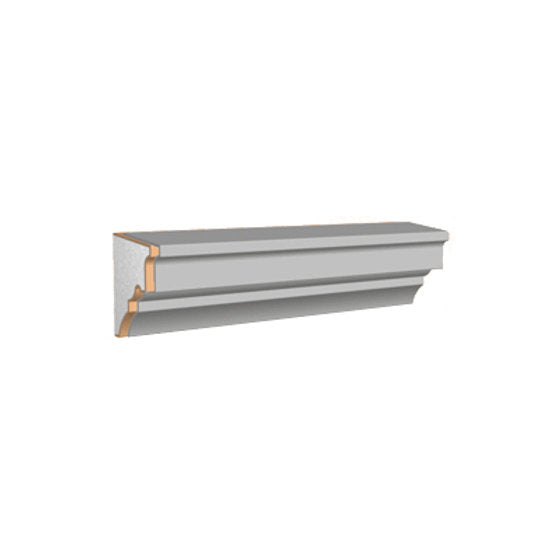

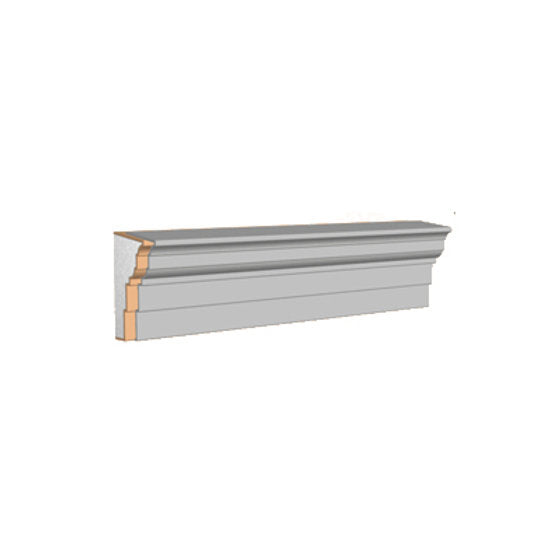

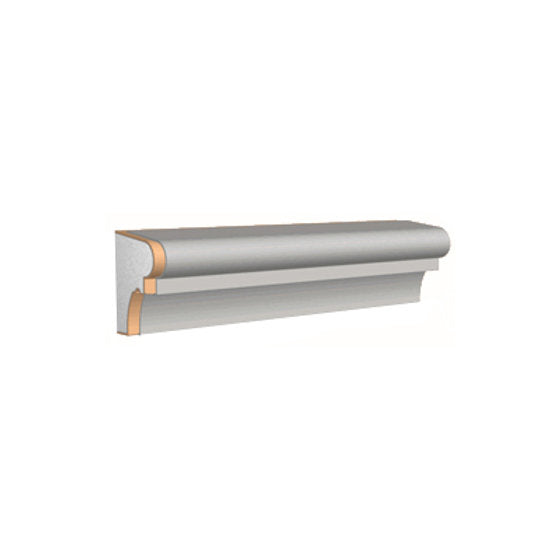

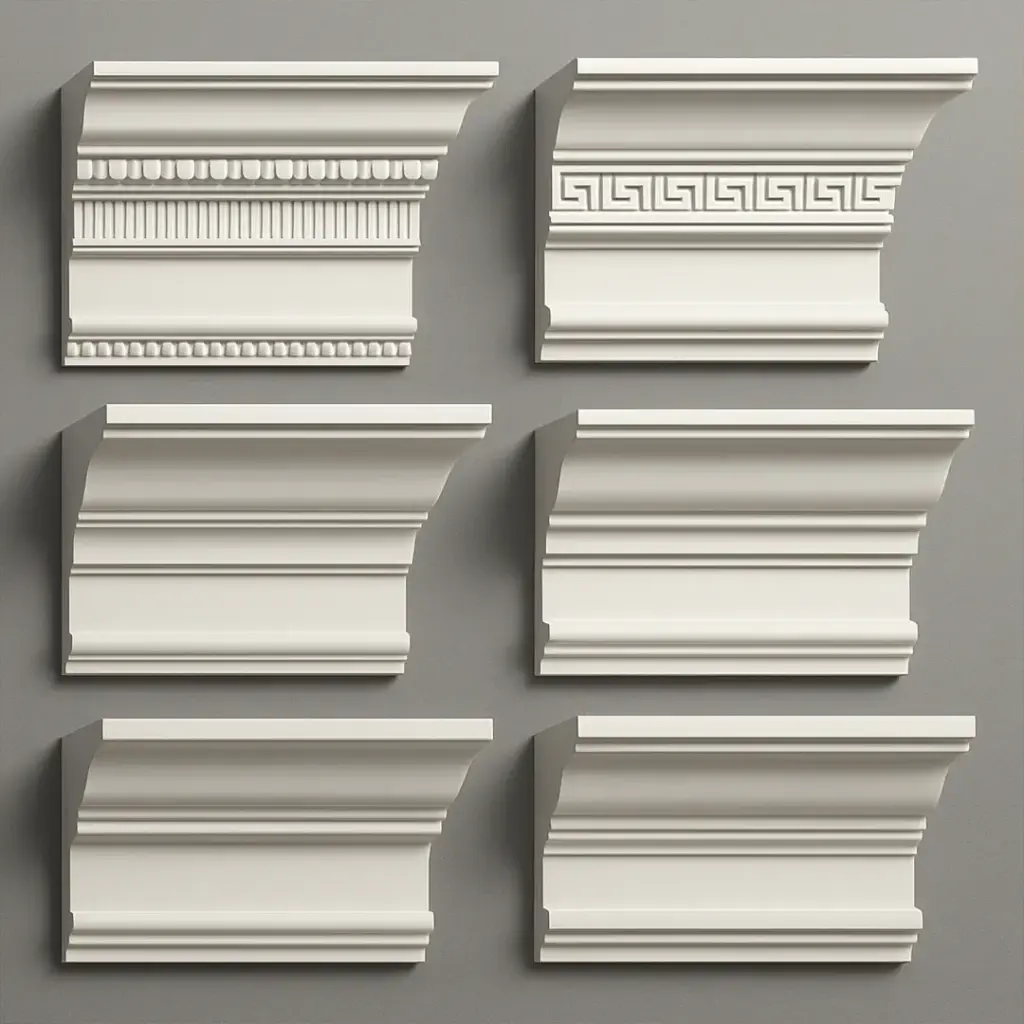

Assortment of decorative moldings

EPS foam molding vs. traditional materials:

The unfair advantage

Stop fighting with heavy, fragile, and outdated materials. Choose a lightweight, indestructible, and fully custom decorative wall molding solution. Built to last, made in the USA.

Requires costly structural reinforcement, specialized framing, and engineering.

Requires expensive, specialized crews and takes weeks, inviting project delays.

Prone to cracking, chipping, and rot. Requires constant, costly repairs and upkeep.

Custom work is prohibitively costly. Your best ideas often get value-engineered out.

Massive labor and material costs are compounded by engineering and inevitable long-term repairs.

Mounts directly to any surface. No structural engineering or reinforcement needed.

A small crew installs in hours, slashing labor costs. No mess, no specialized skills required.

Waterproof shell won't crack, chip, or rot. Built to last for decades in any climate.

If you can design it, we can create it. Complex curves and custom profiles are easy and affordable.

Drastically reduced labor, shipping, and equipment costs plus zero maintenance. A smarter long-term investment.

Сustom decorative moldings

How to order architectural moldings

From your initial CAD file or rough sketch to job site delivery—our process is engineered for speed, accuracy, and collaboration.

It all begins with a deep dive into your project. We work as your technical partner to transform creative intent into a solid, actionable plan.

- Analyze Your Inputs: We review your architectural plans, CAD files, sketches, and inspirational images to understand your design from every angle.

- Define the Scope: In a collaborative consultation, we discuss the project’s aesthetic goals, site conditions, and technical requirements to ensure a perfect fit.

- Establish a Technical Blueprint: We finalize all specifications, from dimensions to finish textures, creating a clear roadmap for fabrication that aligns perfectly with your vision.

We bridge the gap between concept and cost, providing you with the clarity and confidence to move forward.

- Receive a Detailed 3D Visualization: We create and send you a precise 3D model, allowing you to see exactly how your custom architectural elements will look before production begins.

- Get a Transparent, Itemized Proposal: You receive a clear, comprehensive quote with no hidden fees. We believe in total transparency, so you know exactly what you’re investing in.

- Maintain Complete Control for Final Approval: We don’t proceed until you are 100% satisfied. You have the final say on the design and budget before we move to the next stage.

This is where your approved design becomes a physical reality, crafted with an obsessive focus on quality in our 45,000 sq. ft. workshop.

- Execute with Robotic Accuracy: Our state-of-the-art CNC hot-wire machines carve your architectural elements with flawless precision, matching your approved 3D models to the exact specification.

- Armor for a Century of Performance: Our skilled artisans apply our signature Polyurea hard coat, creating a seamless, impact-resistant, and weatherproof shell designed for decades of durability.

- Verify Through Rigorous Quality Control: Every single piece undergoes a multi-point inspection to ensure it meets our exact standards for shape, finish, and structural integrity.

Our commitment extends all the way to your job site, ensuring a smooth and successful installation.

- Protect with Secure, Custom Crating: We build specialized shipping crates for every project, guaranteeing your elements arrive in pristine, ready-to-install condition.

- Streamline Your Installation: Your pieces are delivered pre-assembled and lightweight, designed to slash on-site labor time and eliminate the need for heavy machinery.

- Support Your Crew to the Finish Line: We provide detailed installation guides and offer live Zoom support to answer your team’s questions, guaranteeing a perfect final fit.

It all begins with a deep dive into your project. We work as your technical partner to translate creative intent into a solid, actionable plan.

- Analyze Your Inputs: We review your architectural plans, CAD files, sketches, and inspirational images to understand your design from every angle.

- Define the Scope: In a collaborative consultation, we discuss the project’s aesthetic goals, site conditions, and technical requirements to ensure a perfect fit.

- Establish a Technical Blueprint: We finalize all specifications, from dimensions to finish textures, creating a clear roadmap for fabrication that aligns perfectly with your vision.

We bridge the gap between concept and cost, providing you with the clarity and confidence to move forward.

- Receive a Detailed 3D Visualization: We create and send you a precise 3D model, allowing you to see exactly how your custom architectural elements will look before production begins.

- Get a Transparent, Itemized Proposal: You receive a clear, comprehensive quote with no hidden fees. We believe in total transparency, so you know exactly what you’re investing in.

- Maintain Complete Control for Final Approval: We don’t proceed until you are 100% satisfied. You have the final say on the design and budget before we move to the next stage.

This is where your approved design becomes a physical reality, crafted with an obsessive focus on quality in our 45,000 sq. ft. workshop.

- Execute with Robotic Accuracy: Our state-of-the-art CNC hot-wire machines carve your decorative architectural shapes with flawless precision, matching your approved 3D model to the millimeter.

- Armor for a Century of Performance: Our skilled artisans apply our signature Polyurea hard coat, creating a seamless, impact-resistant, and weatherproof shell designed for decades of durability.

- Verify Through Rigorous Quality Control: Every single piece undergoes a multi-point inspection to ensure it meets our exacting standards for form, finish, and structural integrity.

Our commitment extends all the way to your job site, ensuring a smooth and successful installation.

- Protect with Secure, Custom Crating: We build custom shipping crates for your elements, ensuring they arrive on-site in pristine, ready-to-install condition.

- Streamline Your Installation: Your pieces are delivered pre-assembled and lightweight, designed to slash on-site labor time and eliminate the need for heavy machinery.

- Support Your Crew to the Finish Line: We provide detailed installation guides and offer live Zoom support to answer your team’s questions, guaranteeing a perfect final fit.

Our project gallery

Engineered solutions for visionary projects

Whether you’re restoring a landmark or building a new one, our system is engineered for your success

Finally, achieve the details you’ve always envisioned. We fabricate custom profiles to your exact CAD specifications, enabling multi-layered cornices, grand ceiling details, and dramatic decorative wall molding panels without the weight and budget constraints of the past.

Add a high-end finish that dramatically increases property value and appeal, without killing your timeline. Our lightweight moldings install incredibly fast, helping you complete projects ahead of schedule and under budget.

Create unforgettable brand environments. From the grand entrance of a hotel to the sophisticated interior of a luxury retailer, our durable moldings withstand high-traffic use and require zero maintenance.

Replicate ornate, historical profiles with 100% accuracy but without stressing the original structure. Our system is the perfect solution for restoring architectural heritage with modern, long-lasting materials.

Before and after:

From bland box to architectural statement

Discover our workHow moldings communicate quality

Architectural details are the language of quality. They speak before you do. A well-designed molding system tells clients, guests, and tenants that you invest in excellence and permanence. It’s the difference between a space and an experience.

- An Image of Permanence and PrestigeCrisp, multi-layered moldings create a sense of solidity and craftsmanship. It’s a visual cue that signals stability and attention to detail, building trust and confidence in your brand or property from the first glance.

- Engineered for Zero HeadachesUnlike wood that splits or plaster that cracks, our composite decorative molding is engineered to be inert. It will look as perfect in year twenty as it did on day one, with nothing more than a simple wipe-down. This is a true "set it and forget it" investment.

- A Signature Look for Your BrandYour space should be an extension of your brand. We can create custom profiles that are unique to your project, allowing you to build a signature architectural identity that sets you apart from the competition.

Client testimonials

From your first idea to the final installation — our process is clear, fast, and designed to make every detail simple.

FAQ

How should we care for panel surfaces?

Just dust them with a soft cloth. If you’d like a new color, repaint in place—foam accepts coatings easily.

Can you create custom shapes not listed in catalogs?

Absolutely. We specialize in custom designs. In a Sarasota gallery, we built wave-shaped panels that didn’t exist before; they became the signature of the space.

How heavy is a foam decorative panel?

Very light—several times lighter than plaster or wood. That reduces structural load and simplifies handling.

How do you ensure dimensional accuracy?

Every element is checked against CAD and visually inspected. That’s why installation fits perfectly on the first try.

Is foam molding suitable for exterior applications?

Yes. Foam is ideal for façades and storefronts—UV-stable and resistant to weather.

What do we do if part of a wall panel gets damaged?

If one section is damaged—it’s easy to fix. No need to replace the whole wall. We simply restore that area, and once it’s repainted, it’s as good as new.

Do you deliver everywhere in the United States, even remote areas?

Yes, we ship to continental US. From Miami to Montana—we manage delivery logistics to match your construction schedule.

Can we integrate LED lighting or fixtures into the profiles?

Of course. Foam works perfectly with LED systems, diffusing light beautifully and adding subtle depth.

Why should we choose foam instead of plaster or wood?

Because foam saves time, reduces weight, and eliminates maintenance headaches while looking equally refined.

Do we provide technical documentation for approvals and installation?

Always. CAD drawings, submittals, and clear packaging details accompany every shipment.

What about long-term warranty and performance?

We back our products with a 20-year warranty. Foam remains stable, strong, and visually flawless for decades.

Is decorative wall molding ideas relevant to modern minimalist design?

Very much so. Subtle relief and refined geometry give minimalist interiors depth and elegance.

How do architectural interior moldings support brand experiences?

By shaping first impressions—entries, walls, and corridors—into memorable branded spaces.

& specification catalog

Get the definitive guide to our custom decorative architectural foam shapes. This free catalog is packed with hundreds of design profiles, detailed technical specifications, and real-world project applications.

Have a project in mind?

Our dedicated specialists are ready to collaborate with you, turning your concept into a detailed plan with a transparent budget. Let’s bring your vision to life!

More architectural shapes

We provide architects, builders, and homeowners with turnkey decorative elements that transform any project — fast, easy, and cost-effective.

Decorative Moldings

Over 25 years in the field taught us a simple truth: space isn’t just walls and ceilings. It’s mood, energy, and identity. And molding is the instrument of professional finish that gives that space meaning and expression. Architects, designers, contractors, developers—everyone who creates distinctive places—knows it’s not about “decorating,” it’s about delivering a sense of value and intention.

If once decorative elements were a luxury, today decorative wall molding is part of the architectural language. It hides joints, visually enlarges rooms, adds depth, and reinforces the concept. We’ve watched even minimalist interiors come alive once well-designed decorative wall moldings are introduced—the wall starts to breathe, light and shadow play, the overall narrative clicks into place.

For teams building not just square footage but atmosphere, this is the kind of move that creates a wow effect without runaway costs.

What it is and core functions

Foam molding is a family of profiles that add volume, style, and architectural expression to exteriors and access. They can run along walls and ceilings, frame doors and windows, accent columns and niches – the designer’s tool to give a room “oxygen.”

Key functions we emphasize:

- Aesthetic. Profiles create light–shadow relief, refine proportions, and bring visual harmony.

- Functional. They conceal transitions or joints, allow for integrated lighting or even hidden systems.

- Zoning. Profiles help articulate wall sections or define areas within open plans.

- Brand/identity. In commercial projects, decorative wall molding ideas for access help build recognizable ambiance and deliver a branded spatial experience.

We recall a small but impeccably styled boutique hotel in Miami where we proposed volumetric profiles that visually “raised” the walls, making the lobby feel larger. The owner later admitted that this single move sold the atmosphere of “boutique luxury.”

History and evolution

Architectural decoration has existed since antiquity. Architectural moldings for access adorned palaces, temples, theaters. In the 21st century the idea remains, but the material shifted. Instead of plaster or wood, architectural foam unlocked new possibilities.

When we started in the late ’90s, the U.S. market leaned heavily on plaster and wood. Today, priorities are function, minimalism, and durability. Modern interior architectural moldings are not just ornament; they’re engineered design components that work with the space.

A recent project: a contemporary residential complex in Atlanta. The client wanted “strict geometry without extra weight.” We designed slender foam profiles—visually light yet dimensionally precise. The facade reads modern and refined, without the weight or cost penalties of traditional materials.

Materials and technology

We manufacture every decorative wall molding and decorative wall molding panels element exclusively from architectural foam – a material that blends lightness, strength, and fabrication flexibility.

Why foam only

Foam is a modern engineering material crafted for architectural solutions, for example for access. Its advantages are clear:

| Feature | Technical Value & Performance |

|---|---|

| Lightweight | Ensures easier handling and lower transport costs compared to traditional plaster or wood materials. |

| Strong | Features a stable structure that resists moisture penetration and prevents cracking or warping over time. |

| Durable | Engineered to eliminate issues related to shrinkage, rot, insect damage, or mold growth. |

| Surface Realism | Advanced texturing techniques imitate wood or stone so convincingly that even seasoned professionals are surprised. |

| Eco-aligned | Utilizes safe, high-quality materials that strictly adhere to U.S. manufacturing and quality standards. |

Everything we make comes from our own U.S. production, giving us flexibility and control: no dependence on outside suppliers, easy tailoring to the brief, and full fidelity to drawings and specifications.

Accuracy, quality control, and logistics

Professionalism shows in predictability. Clients should know exactly what they’ll get and when. That’s why quality control isn’t a phase – it’s our operating system.

- Millimeter-level precision. Every element for access is verified against CAD. When helpful, we prepare 3D mockups to approve form and proportion upfront.

- Visual and structural checks. Before shipment, geometry, rigidity, and surface clarity are inspected.

- Flexible logistics. We schedule deliveries to meet your build sequence so material arrives in great condition at the right stage.

- Packaging and labeling. Each element for access is individually labeled for straightforward storage and on-site handling.

For a Florida restaurant group facing a hard opening date, we scheduled deliveries in installation sequence. Result: zero downtime, interiors ready on schedule, brand delighted.

We’ve also supported architects requesting non-standard angles and dimensions. We customized forms in production and validated them with digital templates so everything aligned perfectly on site. These small details are where engineering partnership beats a commodity supplier.

Comparison with alternatives

| Material | Typical Issues | Foam Advantages |

|---|---|---|

| Wood | Heavy, absorbs moisture, can deform over time. | Foam is light, moisture-resistant, and won’t warp. |

| Plaster | Fragile, slow to work with, and prone to cracking. | Foam is easier to work with and significantly longer-lasting. |

| MDF / Generic Polymers | Limited forms, heavy, and often features weak detailing. | Foam allows for any geometry, texture, and complex architectural style. |

Foam solves both aesthetic and engineering challenges – reducing weight, easing handling, and cutting installation time and risk.

Types and real-world use

Decorative wall molding panels are our flagship. We tailor them to any style, from classic to high-tech. In a Sarasota gallery, we created a softly backlit panel composition that echoed a coastal sunset. Visitors called it “architectural poetry.”

Foam molding for ceilings, accesses and walls helps unify space. In a Jacksonville consulting office, slender lines swept from wall to ceiling. Simple idea, big impact: a cohesive environment that felt taller and wider.

Exterior architectural moldings excel at finishing niches, portals, accesses and window reveals. In a Fort Lauderdale residential complex, we detailed window returns with a stone-like texture—visually premium, technically efficient.

Importance of maintenance and operation

Foam’s day-to-day performance is one of its biggest advantages. It shrugs off moisture, cleans easily, and needs minimal care.

Compared to wood or plaster, upkeep for foam decorative elements for access is dramatically simpler: regular dusting with a soft dry cloth is usually enough. When you want a refresh, repaint in place—foam accepts standard coatings without elaborate prep.

We provide a 20-year warranty with proper operation. Clients often say, “Install it—and forget it.” That’s not hyperbole. Foam doesn’t crack, yellow, wick moisture, or distort.

In a community near Tampa, a designer checked in a decade after completion: “The profiles look like they were installed yesterday.” That’s the power of a well-chosen modern material.

Where it’s used

Hotels and hospitality

Hospitality is about impressions. You need warmth and status in the same breath. Decorative wall molding panels bring visual texture and individuality to lobbies, corridors, and suites. In a Miami resort lobby, vertical panels with integrated backlighting visually lifted the ceiling and brightened the space. Guests lined up for photos against the wall—interior as brand asset.

Commercial offices and showrooms

Clear geometry and recognizable identity are essential. Decorative wall molding supports a coherent corporate language. In an Orlando showroom, we embedded brand motifs directly into panel patterns. A simple move that created a powerful signature feature.

Premium residential developments

Balance matters – visual value with optimized cost. Foam enables refined entries, corridors, and stair halls without the penalties of heavy materials or finicky finishes.

Event and exhibition environments

Temporary builds demand speed and lightness. Foam is ideal: striking look, quick handling, re-usable components after teardown.

Restaurants and bars

Architectural moldingshelp zone spaces, integrate lighting, and reinforce style. In Tampa, geometric panel relief created a kinetic play of light across the dining room, setting an evening mood from the first minute.

Facades and storefronts

Architectural foam thrives where other materials give in. It endures moisture, heat, salt air, and even the moody shifts of coastal weather—making it a natural choice for exterior applications. When used on façades or storefronts, it brings that unmistakable blend of refinement and practicality: sleek, modern, and professional, yet effortlessly low-maintenance.

We’ve seen it many times—storefront cornices that still look freshly installed years later, even under the Florida sun. The texture holds, the color remains vivid, and the surface stays perfectly clean with minimal care. Foam doesn’t just survive outside; it ages gracefully, like good architecture should.

Why partnering with Decorative Architectural Shapes makes the difference

We don’t just ship materials; we build confidence into your project. Every element we produce carries a story of precision, reliability, and craftsmanship born of decades in the industry.

- Proudly Made in the USA. Full in-house production means complete control—no middlemen, no surprises.

- Customization without compromise. Need a specific color, texture, or profile? We’ll create it from your concept with exceptional accuracy.

- Light yet enduring. Foam is feather-light yet strong enough to withstand time, humidity, and heat.

- Guidance at every step. From first sketches to delivery, we stay with you—sharing expertise and ensuring seamless fit.

- See it before you build it. Texture samples, 3D mockups, and renderings help confirm proportions and finishes before production.

- Engineering precision. Every curve, every joint, every millimeter—measured and verified for flawless installation.

- True long-term value. Foam means faster installation, fewer tools, less maintenance, and years of consistent performance.

When you partner with us, you gain more than decorative elements—you gain peace of mind that your design will look right, perform right, and stand the test of time.

& specification catalog

Get the definitive guide to our custom decorative architectural foam shapes. This free catalog is packed with hundreds of design profiles, detailed technical specifications, and real-world project applications.

Have a project in mind?

Our dedicated specialists are ready to collaborate with you, turning your concept into a detailed plan with a transparent budget. Let’s bring your vision to life!